Projection lamp filament and lamp cup focusing and glue injecting device based on mold positioning and method of device

A technology of wick lamps and projection lamps, which is applied in the field of projectors, can solve problems such as low production efficiency, large waste of raw materials, and high production costs, and achieve the effects of improving production efficiency, reducing workload, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

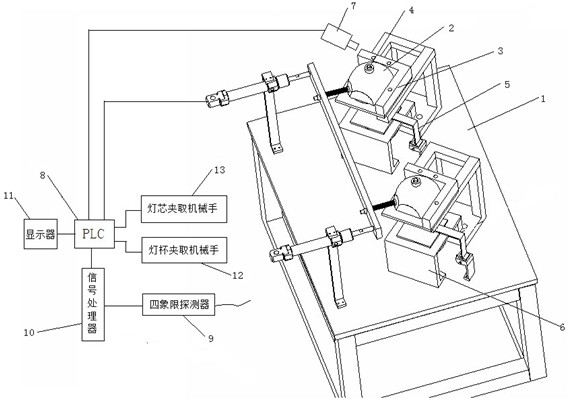

[0030] As shown in Figure 1, the projection wick lamp cup focusing glue injection device based on mold positioning includes workbench 1, lamp cup 2, lamp cup automatic positioning device 3, wick 4, wick automatic positioning device 5, calibration light source device 6, injection Gluing device 7, PLC 8, four-quadrant detector 9, signal processor 10, display 11, lamp cup gripper 12 and wick gripper 13; calibration light source device 6, lamp cup automatic positioning device 3, wick automatic positioning device 5 Fixed on the workbench 1, the lamp cup 2 is fixed on the lamp cup automatic positioning device 3, the wick 4 is fixed on the lamp wick automatic positioning device 5, one end of the glue injection device 7 is connected with the PLC8, and the other end of the glue injection device 7 is placed on the lamp cup 2 Above, the four-quadrant detector 9 is connected to the signal processor 10, the signal processor 10 is connected to the PLC8, and the PLC8 is connected to the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com