Device and method for heating and heat preserving of optical devices

A technology of heating and heat preservation, optical devices, applied in the field of optoelectronics, can solve problems such as poor performance of optical devices, and achieve the effects of improving efficiency, reducing power consumption, and wide temperature control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the method and device of the present invention will be used to automatically control the heating and heat preservation of the FP filter.

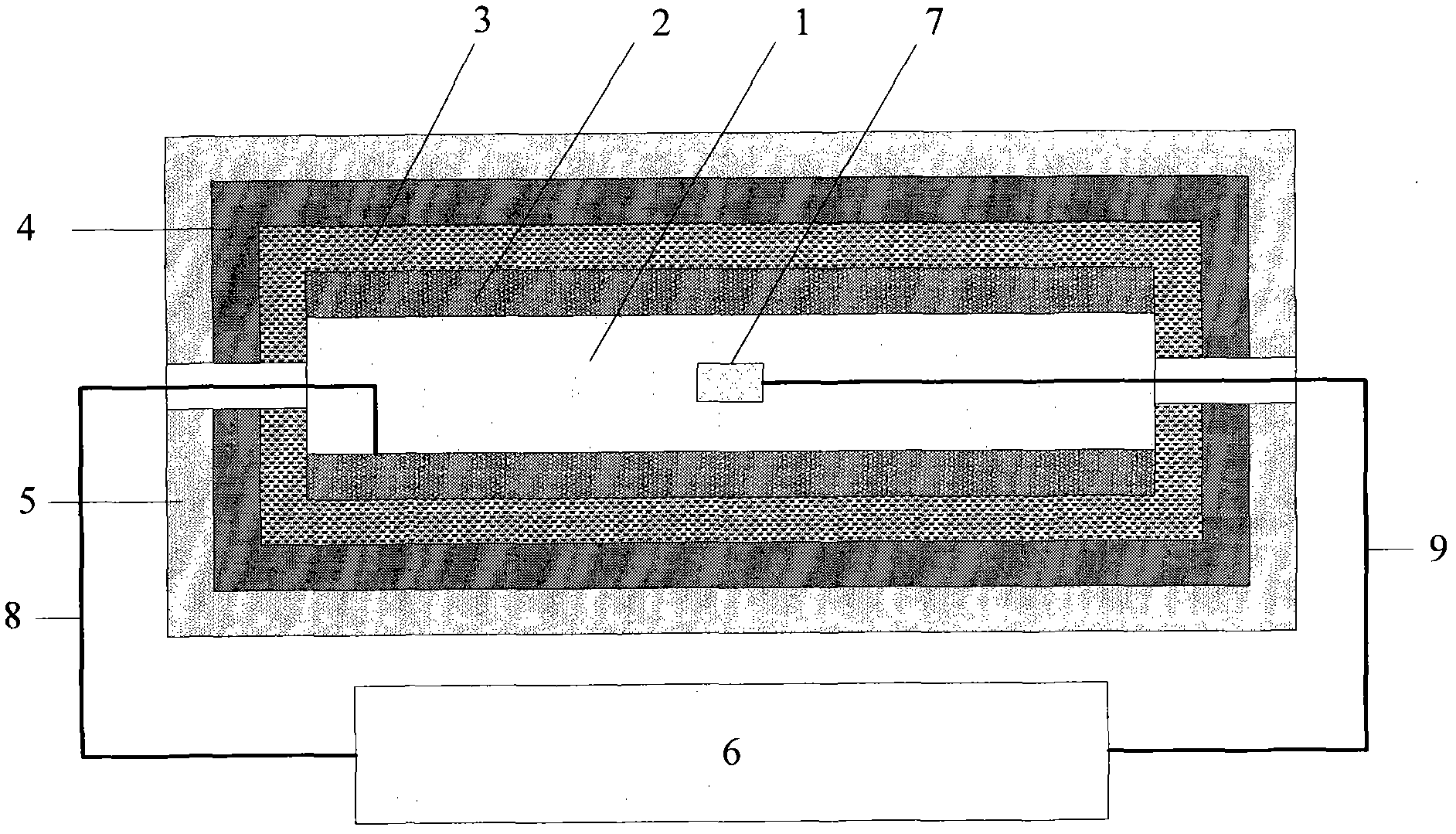

[0037] like figure 1 , the optical device heating and heat preservation device includes a heater 2, a heat insulation layer 3, a waterproof coating 4, a cavity shell 5, a control circuit 6, a thermocouple 7, a heater lead 8, and a thermocouple lead 9.

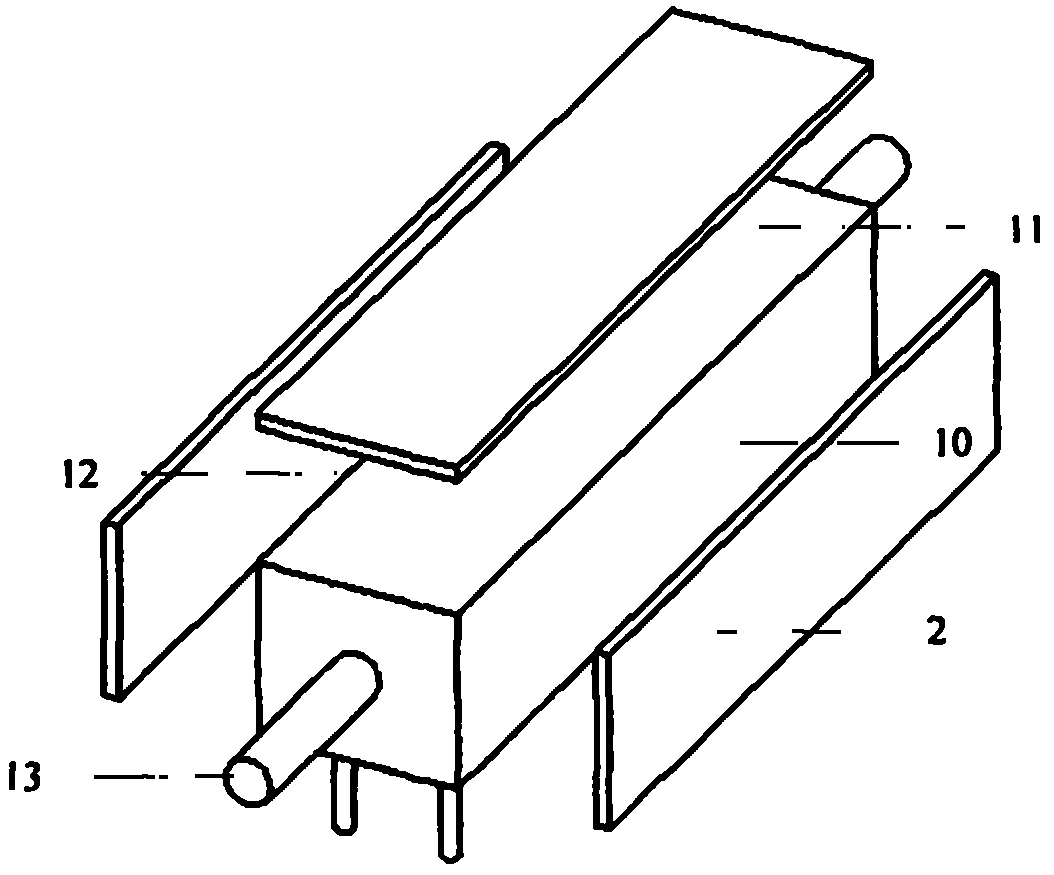

[0038] like image 3 , Figure 4 As shown, the controlled optical device 1 is an FP filter, which is a cuboid device, and the bottom surface 15 of the FP filter has FP filter welding legs 14, and the FP filter leads 13 enter and exit from the left and right sides of the controlled optical device 1. Therefore, the There are optical fiber inlet and outlet holes on the left and right sides of the cavity shell 5 of the heating and insulating device, and welding leg holes are arranged on the bottom surface.

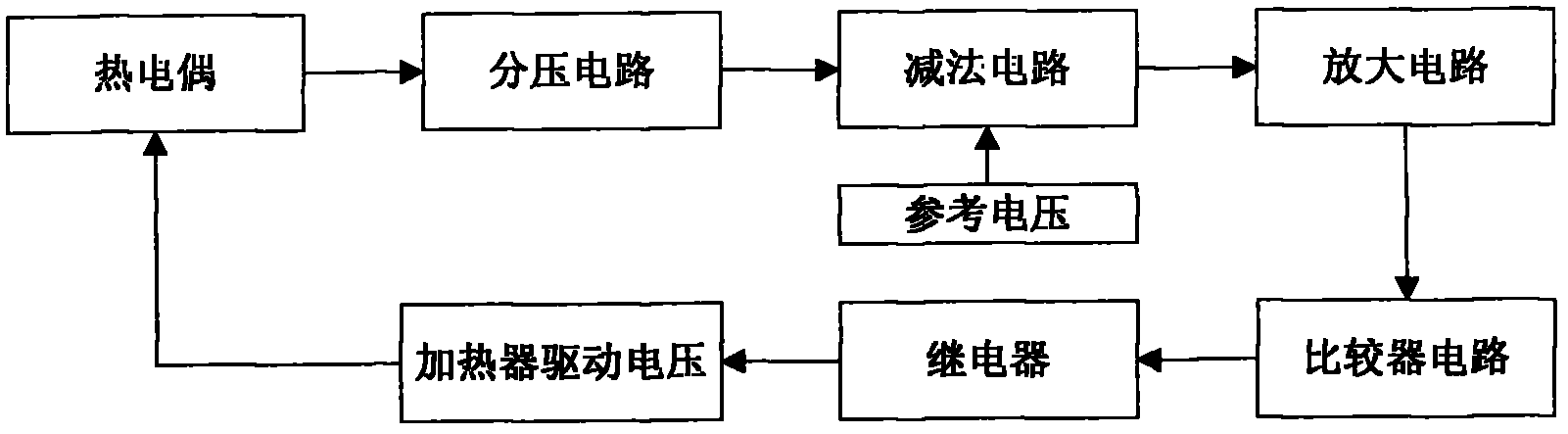

[0039] The connection relationship of the heating and heat...

Embodiment 2

[0052] In this embodiment, the method and device of the present invention will be used to automatically control the heating and heat preservation of the optical fiber etalon.

[0053] like figure 1 , the optical device heating and heat preservation device includes a heater 2, a heat insulation layer 3, a waterproof coating 4, a cavity shell 5, a control circuit 6, a thermocouple 7, a heater lead 8, and a thermocouple lead 9.

[0054] like Figure 5 , Image 6 As shown, the controlled optical device 1 is a fiber optic etalon, which is a cuboid device, and the fiber optic etalon leads 17 enter and exit from the left and right sides of the controlled optical device 1. Therefore, there are optical fibers entering and leaving the left and right sides of the cavity shell 5 of the heating and heat preservation device. hole.

[0055] The connection relationship of the heating and heat preservation device used for the optical fiber etalon is as follows:

[0056] The heater 2 is pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com