Automatic crystal grinding and polishing machine

A grinding and polishing machine, fully automatic technology, applied in the direction of grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve hidden dangers of personal health, can not realize the function of completely unattended, crystal grinding and polishing machine Incomplete and other problems, to achieve the effect of close cooperation between equipment and work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

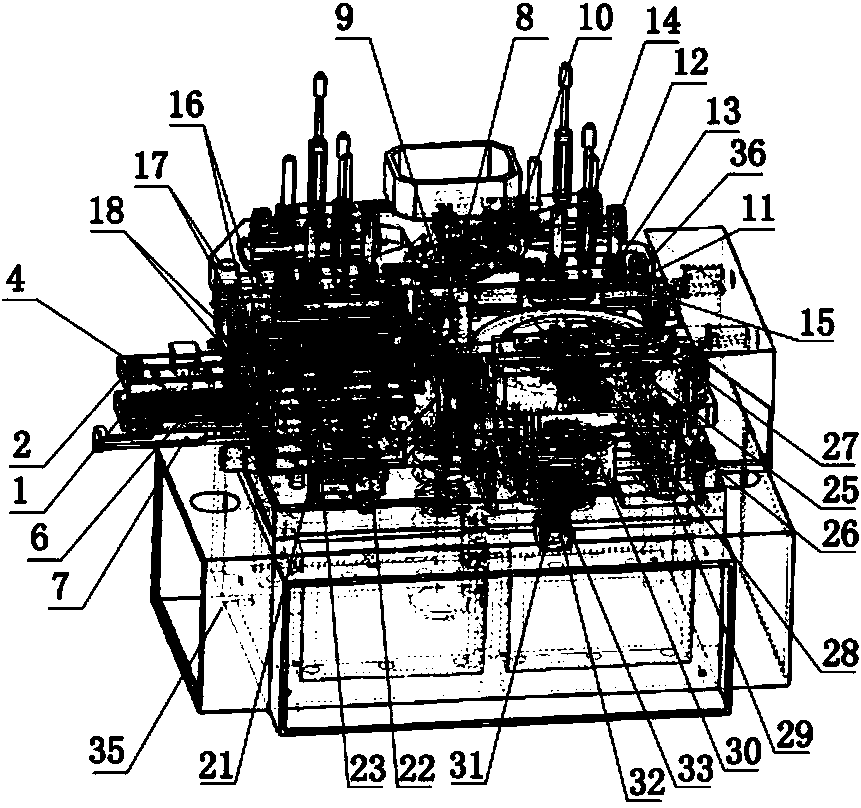

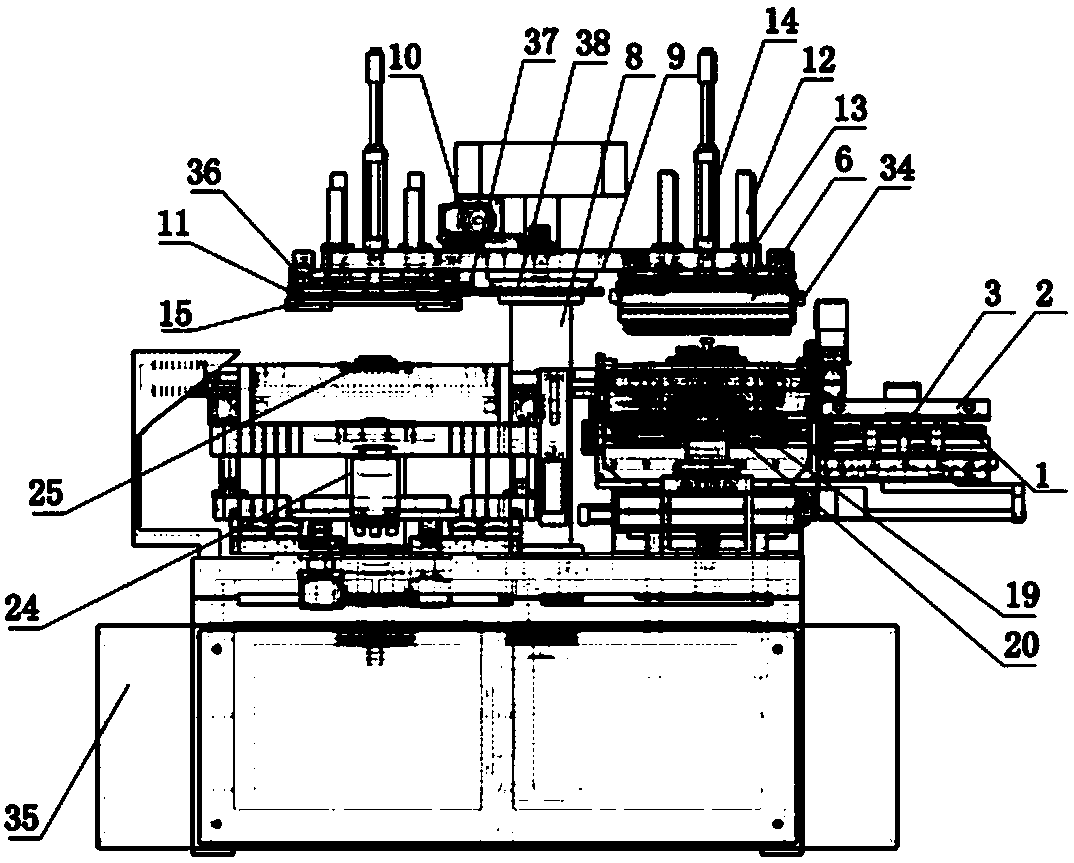

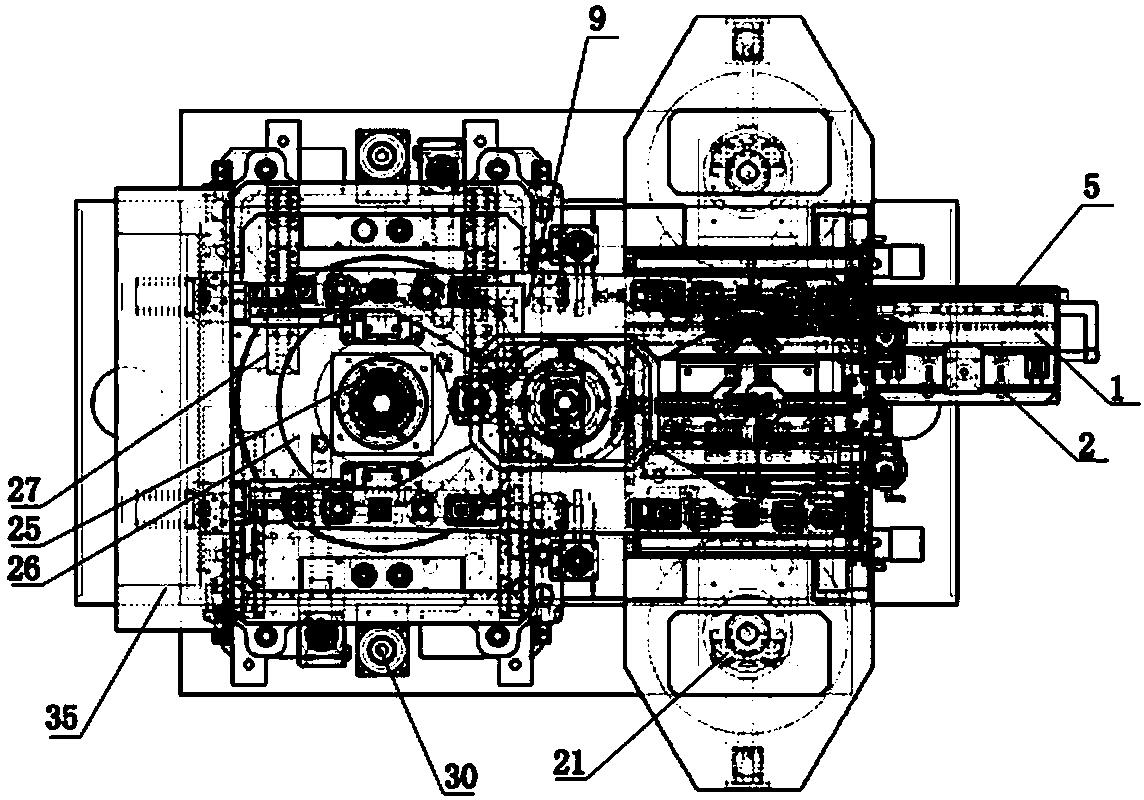

[0035] Example: such as figure 1 , figure 2 with image 3 As shown, the fully automatic crystal grinding and polishing machine of the present invention can be roughly divided into the following parts from the structure: vibrating feeding device, manipulator rotating and shifting device, manipulator lifting and grabbing device, docking feeding and preparation device, hemispherical grinding and polishing Integrated device Ⅰ, docking preparation and stripping device and hemispherical grinding and polishing integrated device Ⅱ;

[0036] Wherein the manipulator rotation shifting device is arranged on the position above the center of the frame 35, and the manipulator lifting and grabbing device is respectively provided with one on the four corners of the manipulator rotating and shifting device, and the manipulator lifting and grabbing devices on the opposite corners form a central symmetrical arrangement; butt loading and The preparation device, the hemispherical grinding and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com