Manufacturing method for millet puffed cake

A production method and millet technology, applied in the field of deep processing of miscellaneous grains, can solve the problem that rice cakes cannot reach the quality level of commercially available rice snow cakes, and achieve the effects of improving thermal expansion performance, quality and thermal expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

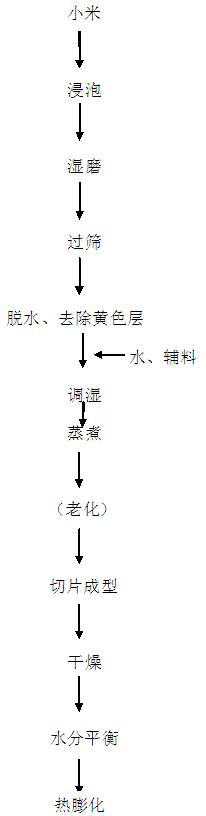

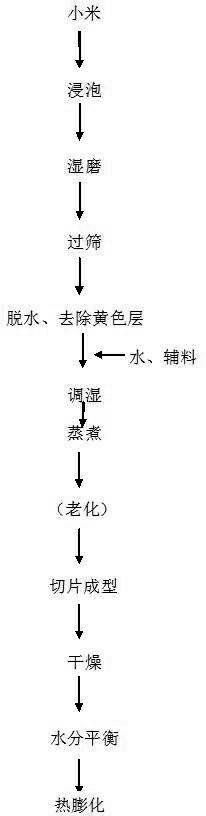

Method used

Image

Examples

Embodiment 1

[0015] Add water to the millet flour to adjust the moisture content to 50%, then add baking soda which accounts for 0%, 0.2%, 0.5%, 1.0% and 2.0% of the mass of the millet flour respectively and stir evenly, cook at 100°C for 25 minutes, and slice into shapes ( 4 cm in diameter and 3 mm in thickness), dried at 50°C to a moisture content of 8%, sealed and stored for 24 h to balance the moisture, and then puffed in an oven at 310°C for 50 s. The puffing effect is characterized by the puffing rate index.

[0016] Expansion rate = volume of puffed rice cake / volume of sample before puffing

[0017] Table 1 Effect of adding amount of baking soda on puffing effect

[0018] Amount of baking soda added (%) 0 0.2 0.5 1.0 Expansion rate 6.3 6.6 6.9 8.2

[0019] It can be seen from Table 1 that the addition of baking soda helps to improve the thermal expansion properties of millet flour, and the greater the addition amount, the more significant the improveme...

Embodiment 2

[0021] Add water to the millet flour to adjust the moisture content to 50%, add 0%, 2%, 4%, 6%, and 8% of the mass of millet flour to the salt, stir well, cook at 100°C for 25 minutes, and slice into pieces (diameter 4 cm, thickness 3 mm), dried at 50°C to a moisture content of 8%, sealed and stored for 24 hours to balance the moisture, and then puffed in an oven at 310°C for 50 s.

[0022] Table 2 Effect of salt addition on puffing effect

[0023] Added amount of salt (%) 0 2 4 6 Expansion rate 6.3 6.4 8.0 8.4

[0024] It can be seen from Table 2 that the addition of table salt also contributes to the improvement of thermal expansion properties of millet flour, and the greater the addition amount, the more significant the improvement.

Embodiment 3

[0026] Add water to adjust the humidity of millet flour to make the moisture content 50%, add salt and baking soda and stir evenly, cook at 100°C for 25 minutes, slice into shapes (diameter 4 cm, thickness 3 mm), and dry at 50°C until the moisture content is 8%. Store in an airtight container to allow moisture to balance for 24 h, and then puff it in an oven at 310°C for 50 s.

[0027] Table 3 The effect of adding salt and baking soda on the puffing effect

[0028] Added amount of salt (%) 0 2 4 Amount of baking soda added (%) 0 0.2 0.5 Expansion rate 6.3 6.8 8.4

[0029] It can be seen from Table 3 that the co-addition of salt and baking soda is more conducive to the improvement of thermal expansion performance of millet flour than the addition of a single variety of auxiliary materials. The study found that with the further increase of salt and baking soda, the puffing rate of millet puffed cakes will also increase, but when the addition inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com