Machine capable of simultaneously carrying out pipe cutting and ring pressing on pipe

A technology for pressing rings and pipes is applied in the field of machines that can perform pipe cutting and ring pressing work on pipes at the same time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

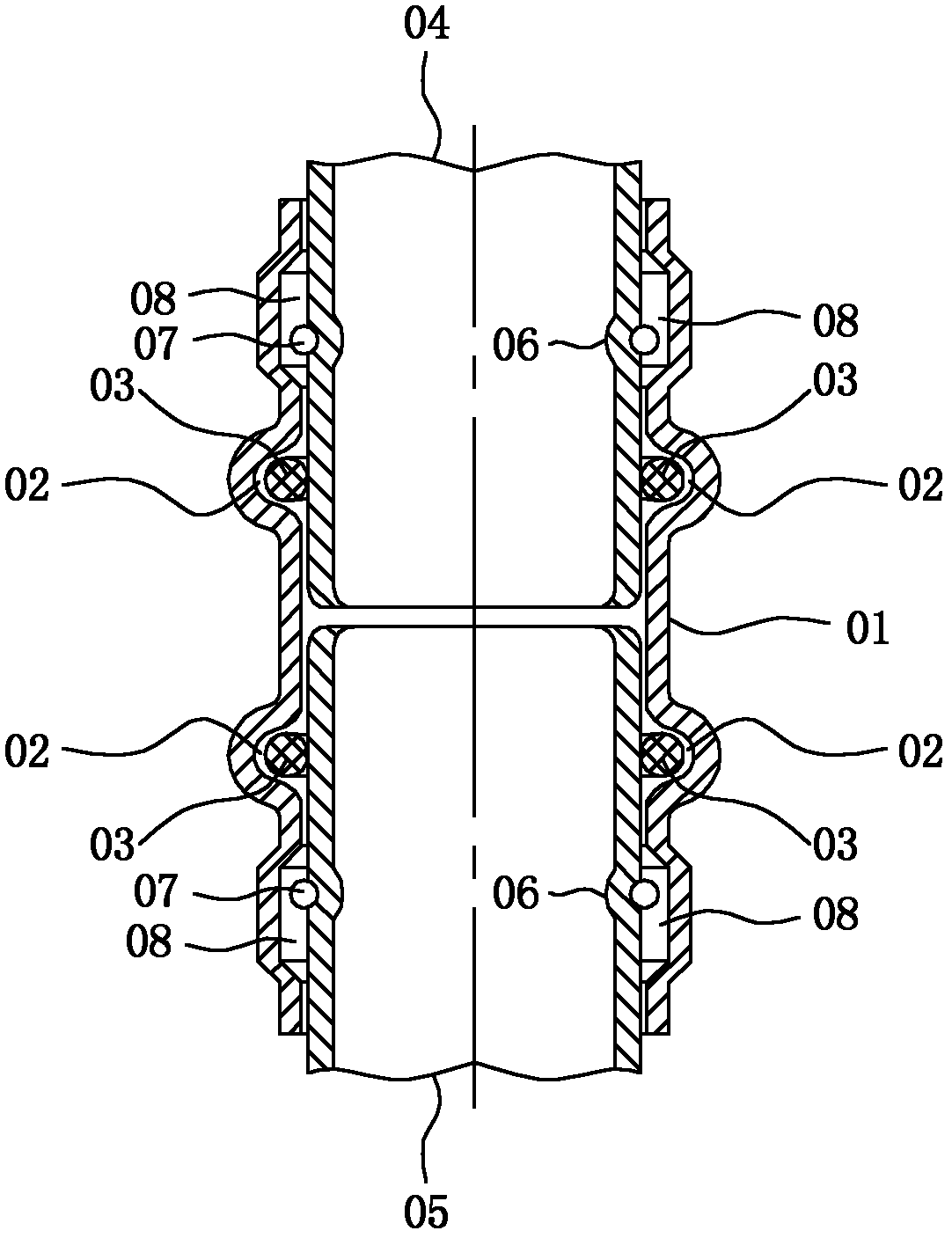

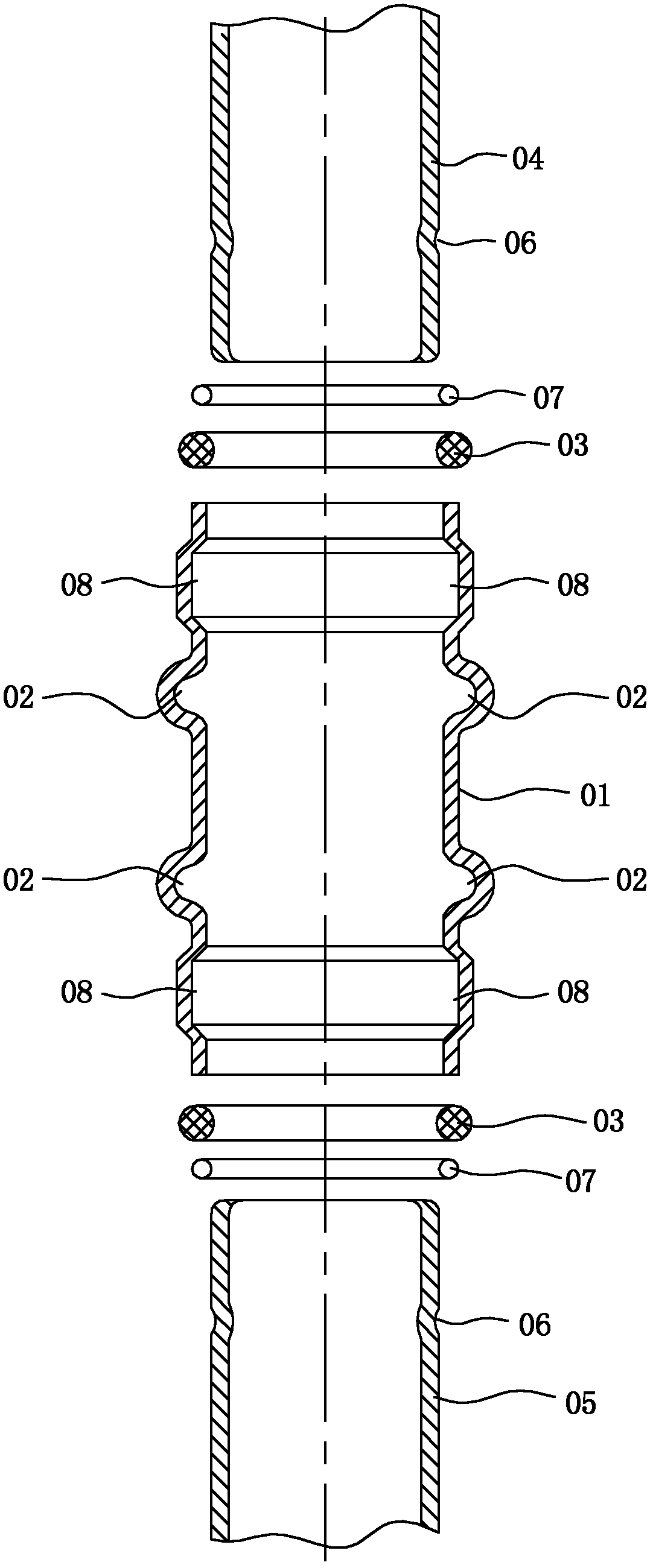

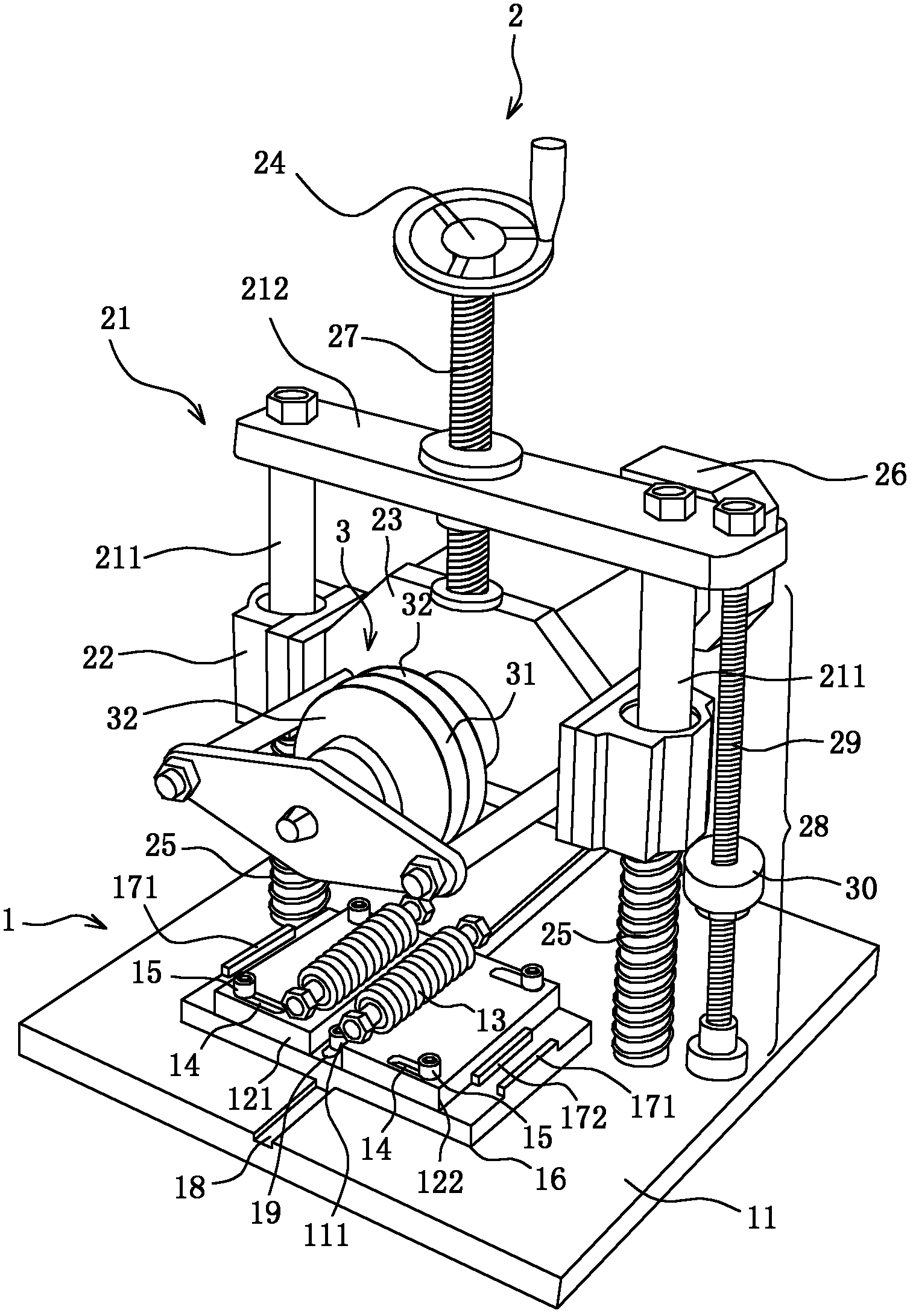

[0020] Now elaborate the present invention in conjunction with accompanying drawing:

[0021] The machine of this embodiment that can simultaneously cut pipes and press rings on pipes includes a supporting device 1 that can freely rotate the pipes, a pressing device 2, a toothless rotary cutter head group 3, and the pressing device 2 drives the toothless The toothed rotary cutter set 3 and the supporting device 1 are pressed against each other. The toothless rotary cutter set 3 is composed of a cutting cutter 31 and a pressure ring cutter 32. The cutting cutter 31 and the pressure ring cutter 32 are parallel to each other. And rotate around the same rotation center line, the radius of the cutting cutter head 31 is larger than the radius of the pressing ring cutter head 32 .

[0022] The supporting device 1 that can make the pipe material a rotate freely is composed of a supporting platform 11, a longitudinal moving plate 16, a left transverse moving plate 121, a right transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com