Automatic adjustment control system and method for segmental prefabricated assembled beam formwork

A prefabricated assembly and automatic adjustment technology, applied in the control/regulation system, program control in sequence/logic controller, non-electric variable control, etc., can solve the problem of not being able to give ten adjustment points, and reduce manual measurement. The probability of errors, the reduction of the probability of input errors, the effect of improving the turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

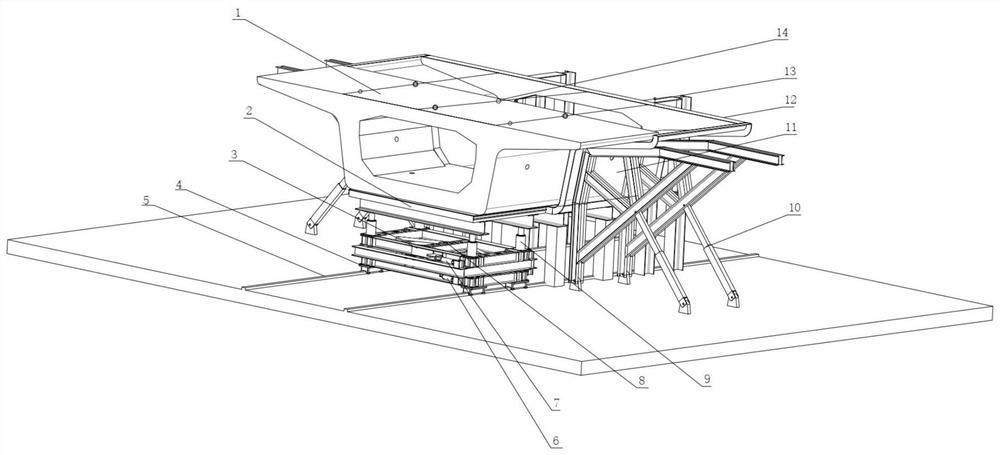

[0033] combine figure 1 As shown, the segmental prefabricated assembled beam formwork automatic adjustment control system includes digital twin technology, numerical control electric screw drive rod device and numerical control measurement system 13, matching beam segment 1, bottom mold trolley 3 and longitudinal moving track 5, the bottom mold The trolley 3 is connected and arranged on the longitudinal moving track 5 through a numerical control electric screw drive rod device, the bottom formwork 2 is connected above the bottom formwork trolley 3, the matching beam section 1 is arranged on the bottom formwork 2, and the matching beam section 1 is provided with a fixed end formwork 12 on the rear side, the numerical control measurement system 13 is set on the fixed end formwork 12, the numerical control measurement system 13 is connected with the digital twin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com