High-speed six-degree of freedom parallel manipulator

A degree of freedom, manipulator technology, applied in the field of robotics, can solve problems such as difficulty in achieving high-speed motion, affecting the dynamic performance of the mechanism, increasing the mass and inertia of moving parts, and achieving the effect of good dynamic performance, uniform force, and high-speed motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments.

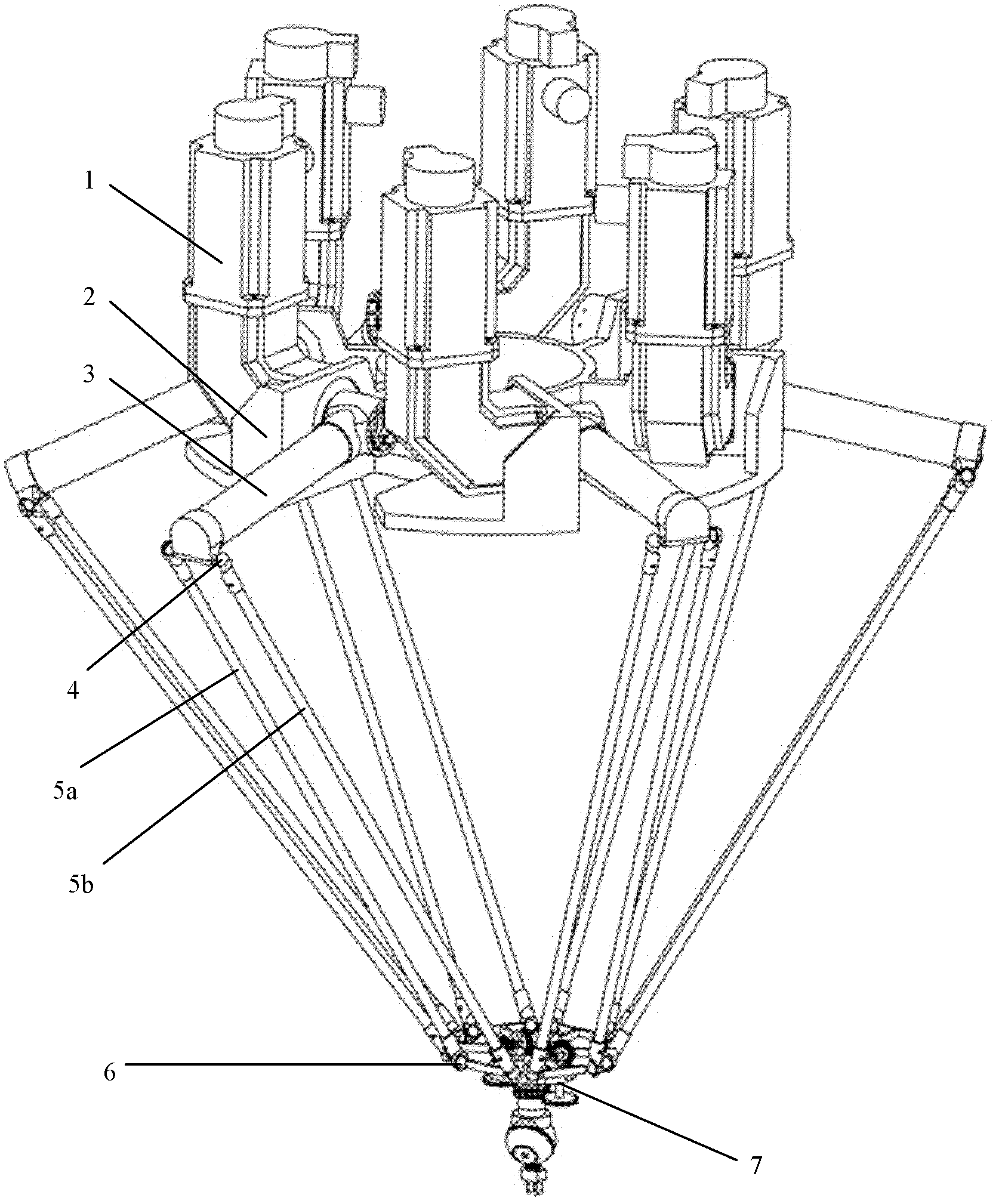

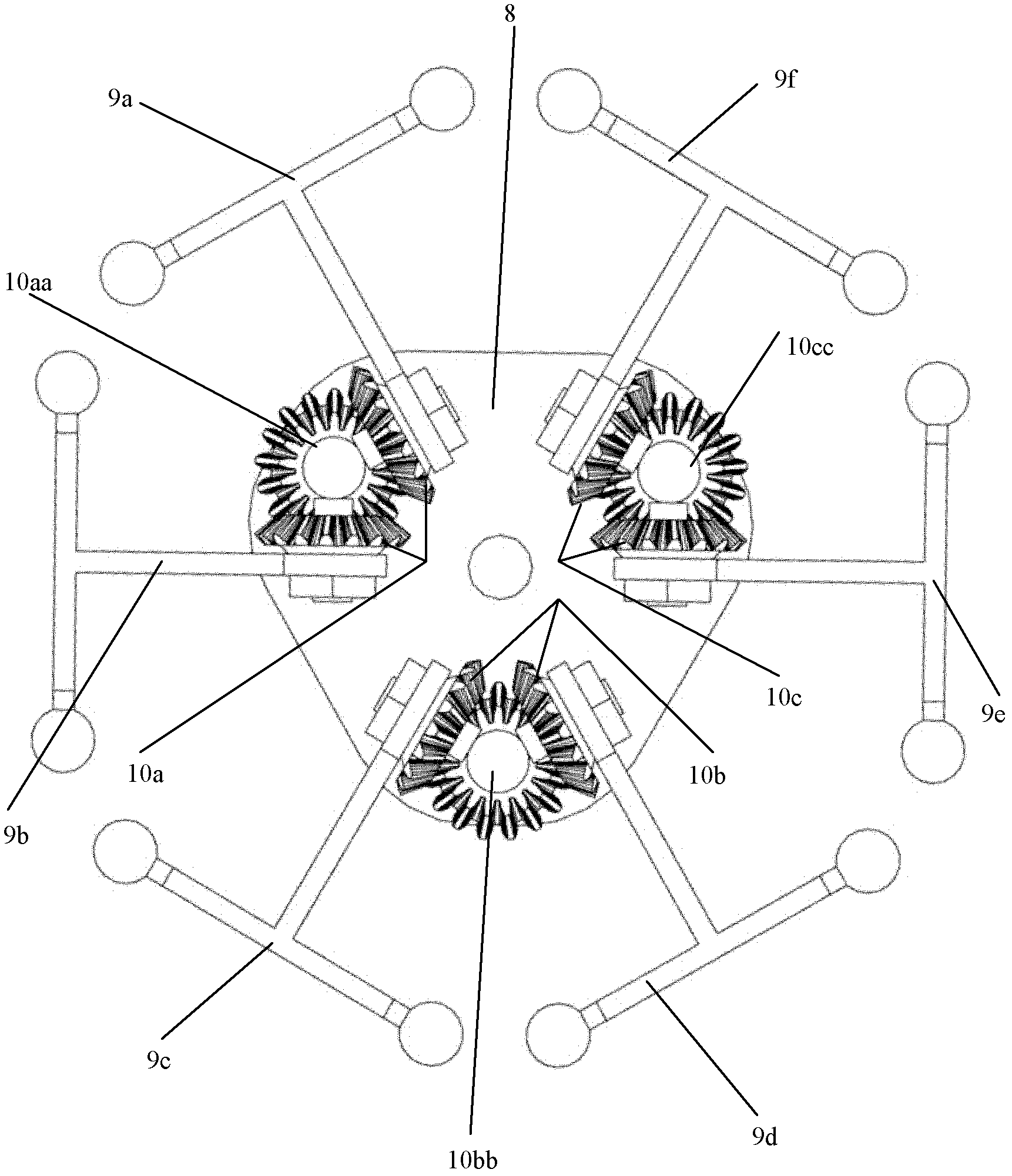

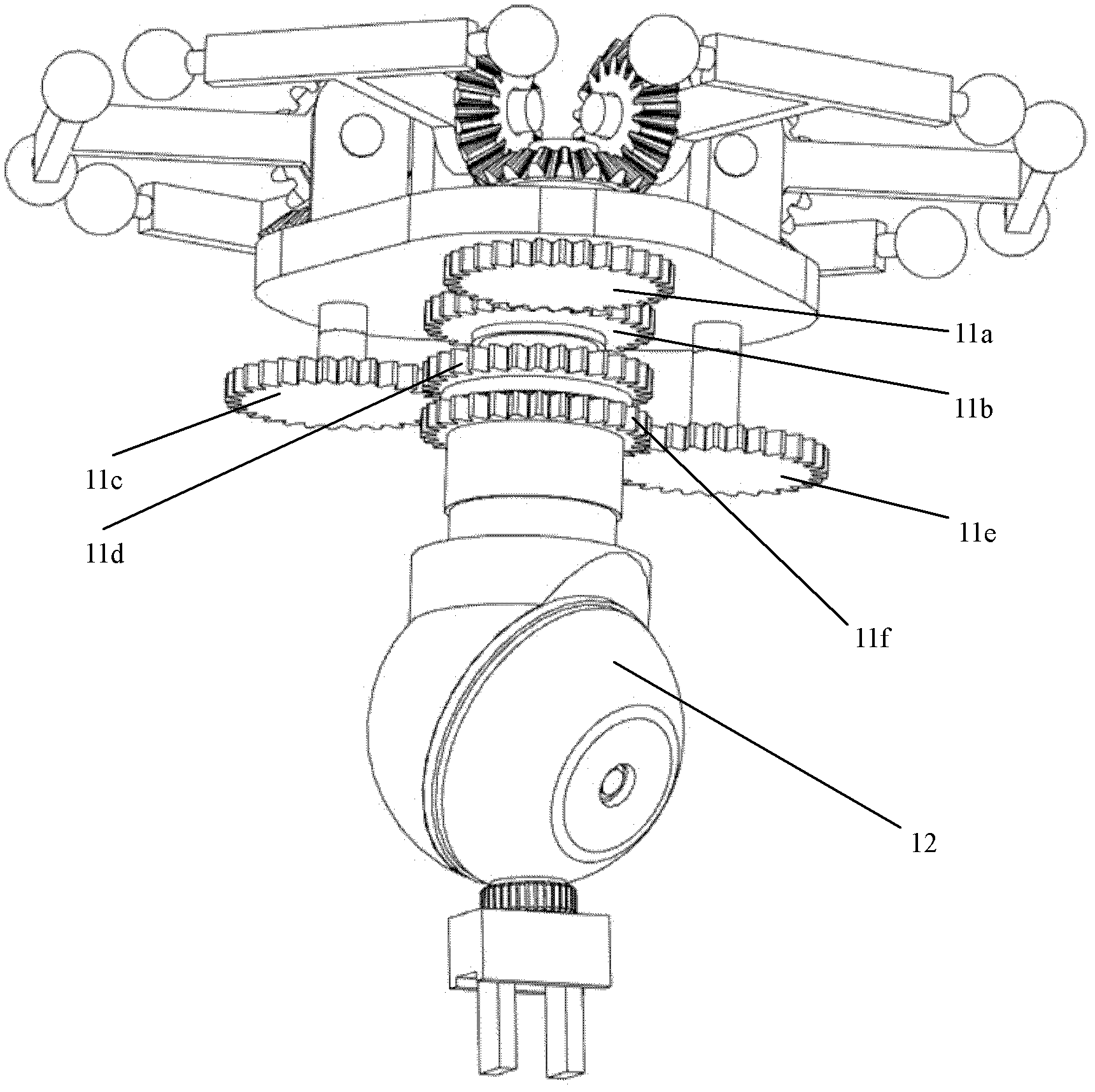

[0017] Such as figure 1 As shown, a high-speed six-degree-of-freedom parallel manipulator of the present invention includes a fixed frame 2, a movable platform 7, a three-degree-of-freedom wrist 12, and six movement branches with the same structure arranged between the fixed frame 2 and the movable platform 7. There are six driving devices 1 fixed on the fixing frame 2.; Each motion branch chain includes a near frame rod 3 and two parallel and equal-length far frame rods 5a, 5b. One end of the near frame rod 3 is fixedly connected to the output end of a driving device 1. The near frame rod 3 The other end is fixedly connected to the upper connecting shaft 4; the driving device 1 provides a degree of freedom of rotation or movement for the near frame rod 3; the same ends of the two remote frame rods 5a, 5b are respectively connected to the respective support through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com