Visual worktable for workpiece conveying on catenary

A catenary and worktable technology, which is applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problem that workpieces cannot be hung on the catenary, loading and unloading workers have high labor intensity, and are not suitable for mass production and other problems, to achieve the effect of simple structure, short working time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

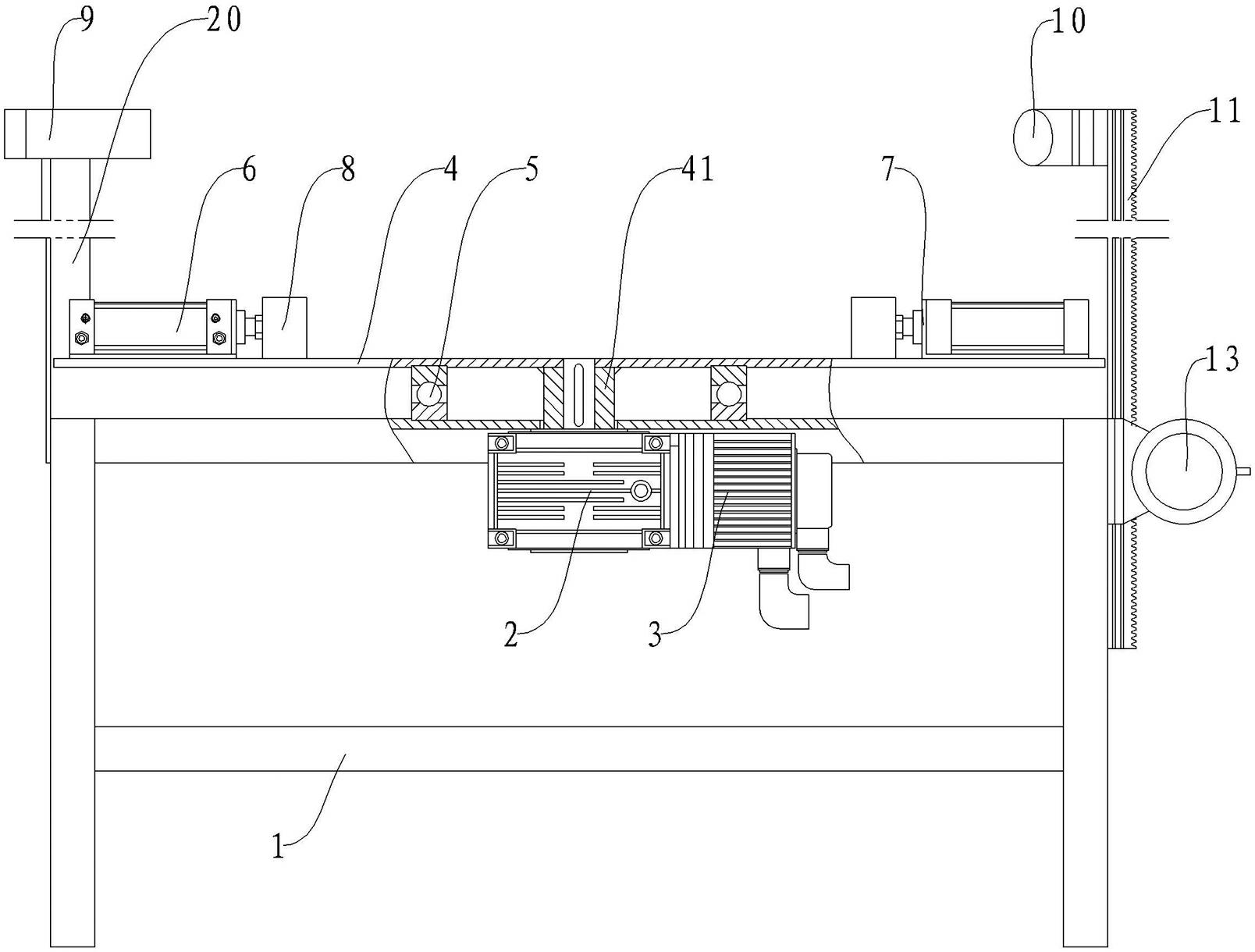

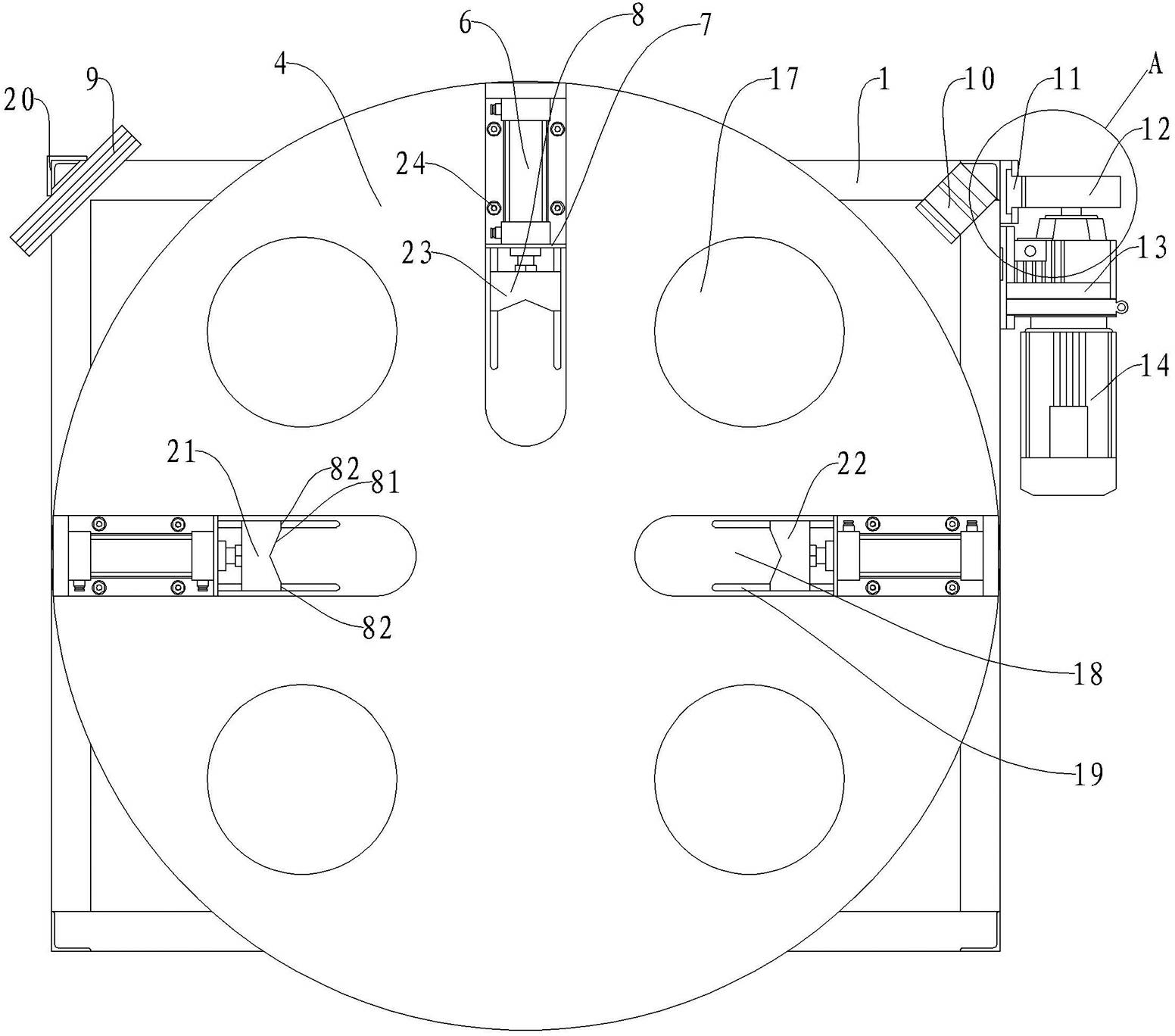

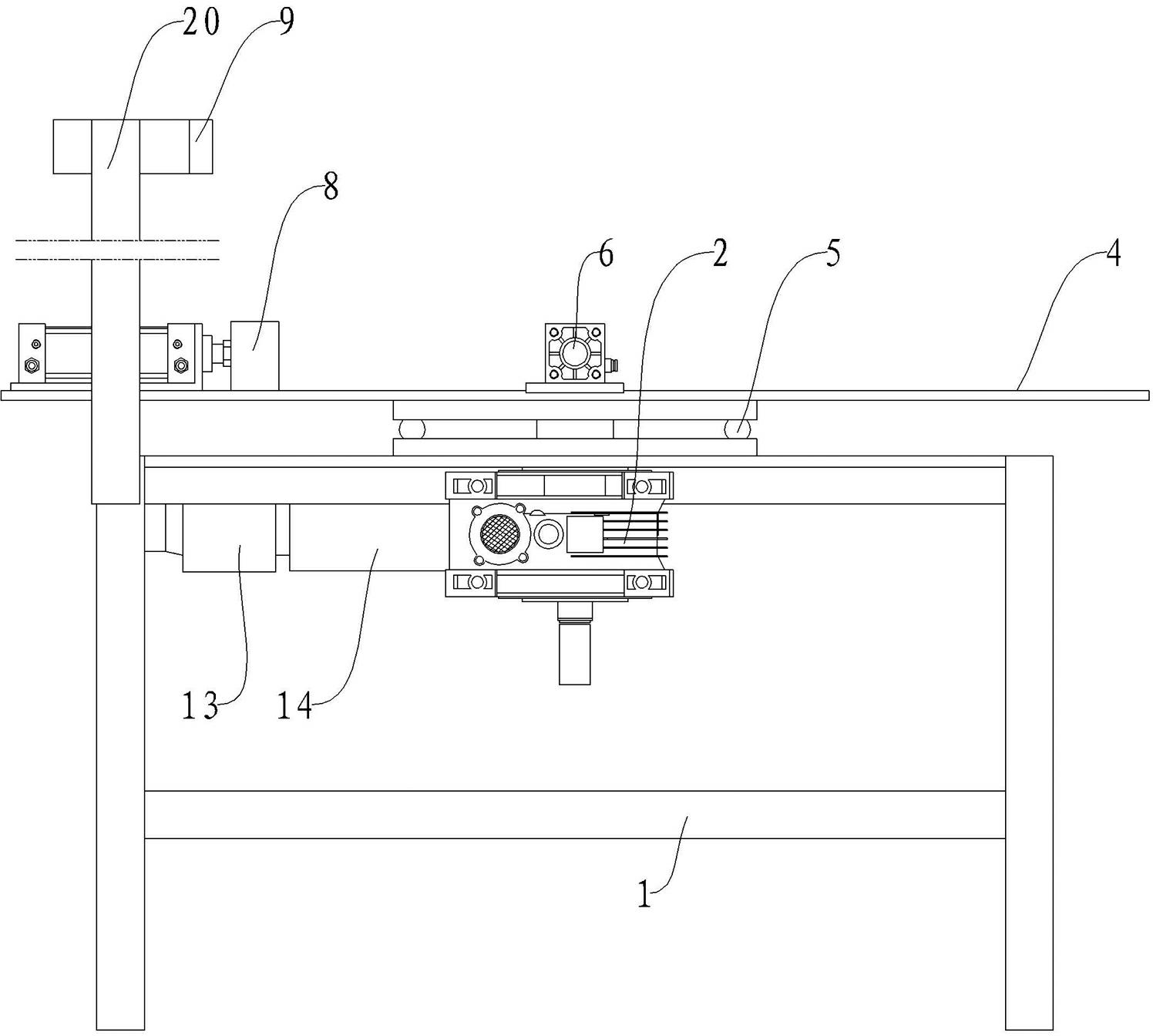

[0025] Such as figure 1 , 2 , 3, the vision workbench for workpiece handling on the catenary mainly includes a workbench 1, a turntable 4, a turntable driving device, and a machine vision system.

[0026] The turntable 4 is arranged above the workbench through the central axis 41 .

[0027] The turntable driving device includes a servo motor 3 and a speed reducer 2 for rotation, and the servo motor 3 and the speed reducer 2 for rotation are fixed on the workbench 1 and are located below the turntable 4 . The rotation is connected by a key between the output shaft of the speed reducer 2 and the central shaft 41 of the turntable. The servo motor drives the turntable to rotate around the central axis through the rotation reducer.

[0028] Because the diameter of the output shaft of the reducer 2 and the central shaft 41 of the turntable are small, the diameter of the turntable is relatively large (the turntable is about 1.2 meters in diameter during actual production), so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com