Construction method for integrally pouring inverted arch concrete by matching trestle with top formwork

A construction method and integral pouring technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems that the concrete cannot be formed according to the designed shape, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

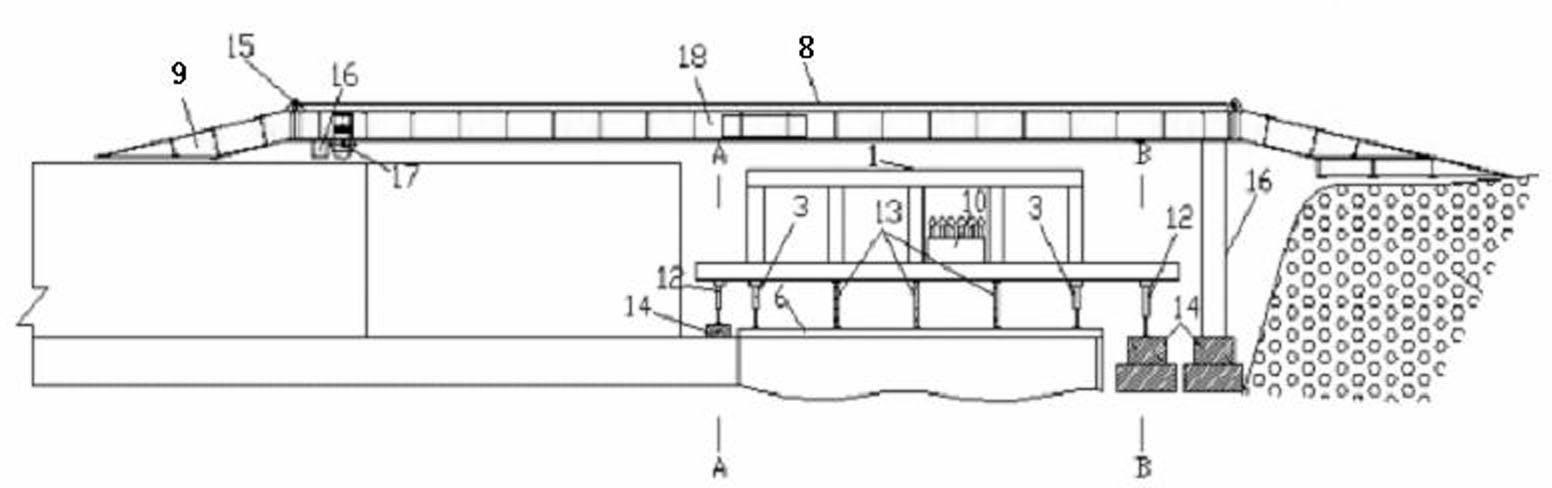

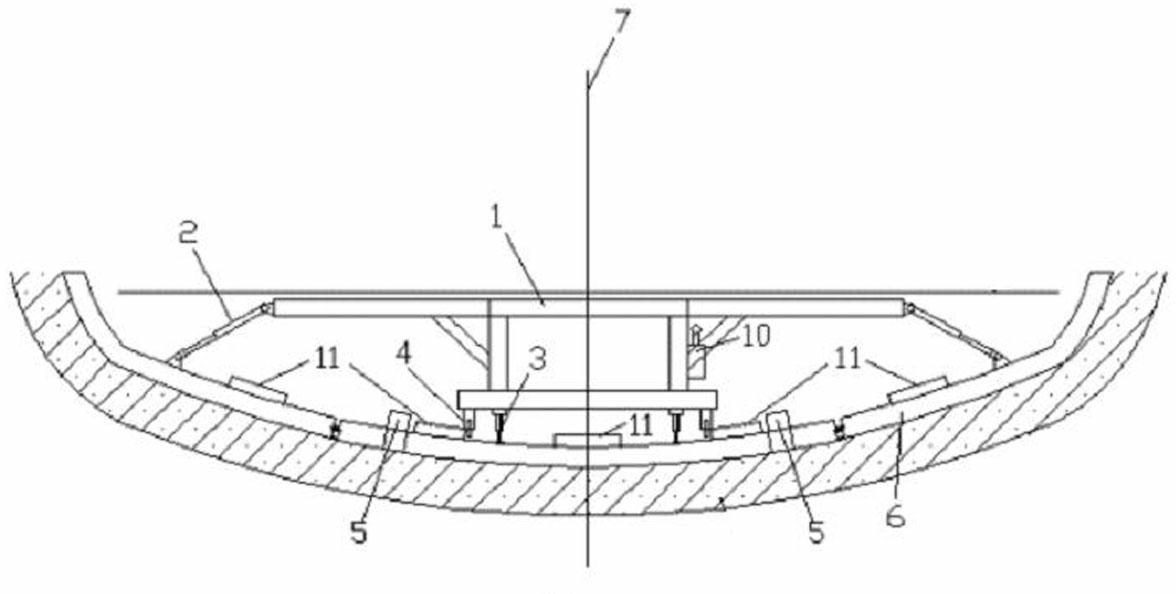

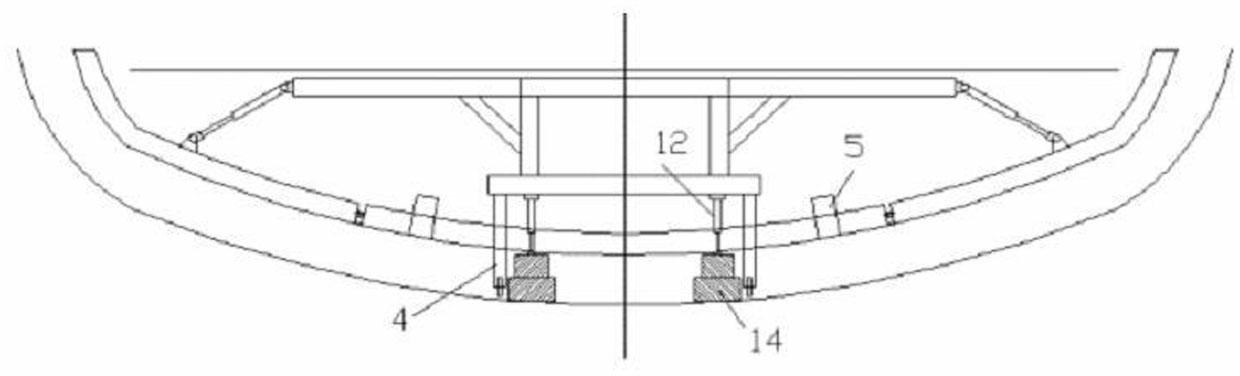

[0023] Such as figure 1 , 2 , a kind of trestle bridge shown in 3,4,5 coordinates the top form integral pouring inverted arch concrete construction method, comprises the following steps:

[0024] (1) Fabrication of the top mold structure: use I-shaped steel to weld the top mold main frame 1, and the top mold main frame and each template 6 pass through the side mold oil top 2, the bottom mold oil top 3, and the top mold structure to lift the oil top 12 connections, the top mold tail end is equipped with a top mold structure walking wheel 4, wherein the templates 6 are connected by a rotating shaft, the side mold oil top 2, the bottom mold oil top 3, and the top mold structure lifting oil top 12 Controlled by the top mold telescopic oil roof control box 10 arranged between the top mold main frame 1 and the template 6;

[0025] (2) Manufacture of trestle structure: Weld the trestle main girder 18 with I-beam, weld the trestle steel plate 8 at the top of the trestle main girder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com