Pumping unit brake locking device

A technology of locking device and pumping unit, which is applied in the direction of mechanical equipment, mining fluid, wellbore/well parts, etc. It can solve the problems of inconvenient operation and unsafe braking, etc., so as to reduce labor intensity, reduce maintenance cost and ensure safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

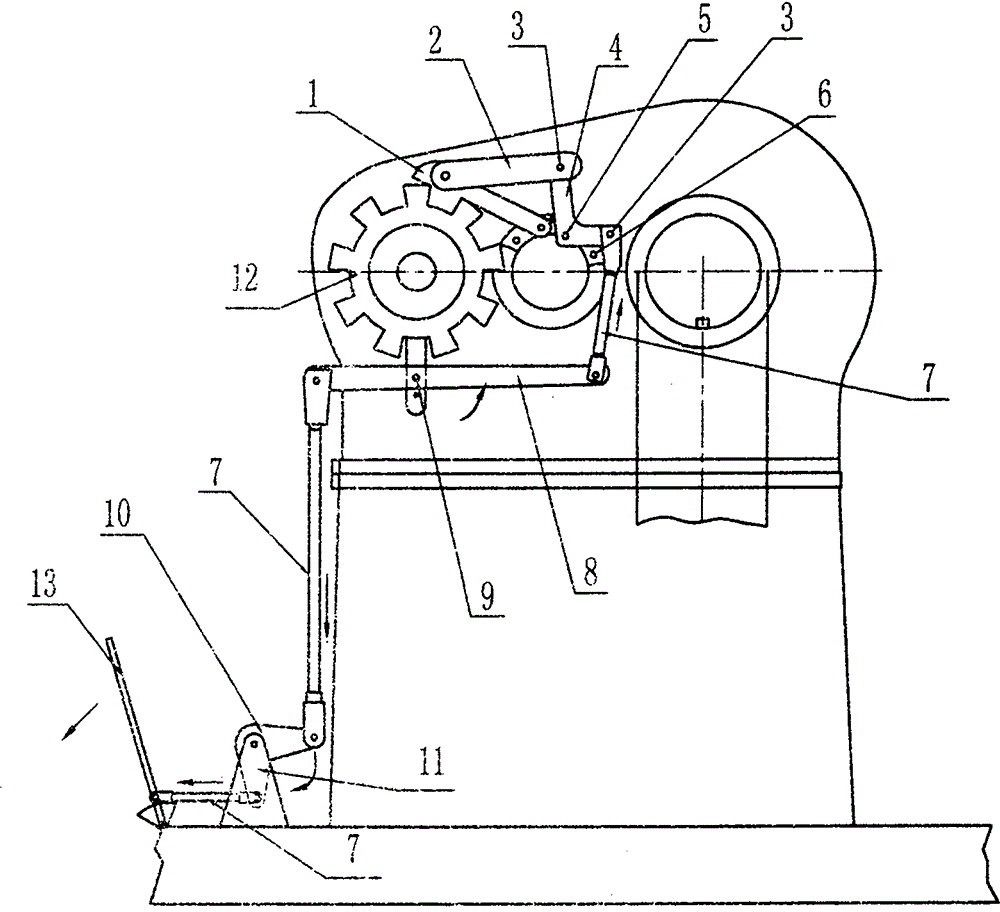

[0009] exist figure 1 In a specific embodiment, 8-12 Great Wall grooves are made along the outer edge of the brake wheel 12, and the brake claw 1 of the reduction box, the connecting plate 2, the right-angle crank arm 4, the connecting rod 7, the rocking arm 8, and the crank arm are connected with the connecting pin 3. 10, the brake connects 13. When braking, the brake handle 13 is tightened, the vertical connecting rod 7 is downward, and the left end of the rocking arm 8 is lowered and the right end is raised, the oblique connecting rod 7 is lifted up, the upper end of the right-angle crank arm 4 is inclined to the left, and the connecting plate 2 pushes the reduction box The brake claw 1 rotates to the left, and the brake claw 1 of the reduction box coincides with the wheel groove, thereby realizing braking and locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com