Patents

Literature

38results about How to "To achieve safe production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum armour tape winding method

ActiveCN103346510AImprove applicabilityImprove securityApparatus for repairing insulation/armouring cablesEngineeringConductor Coil

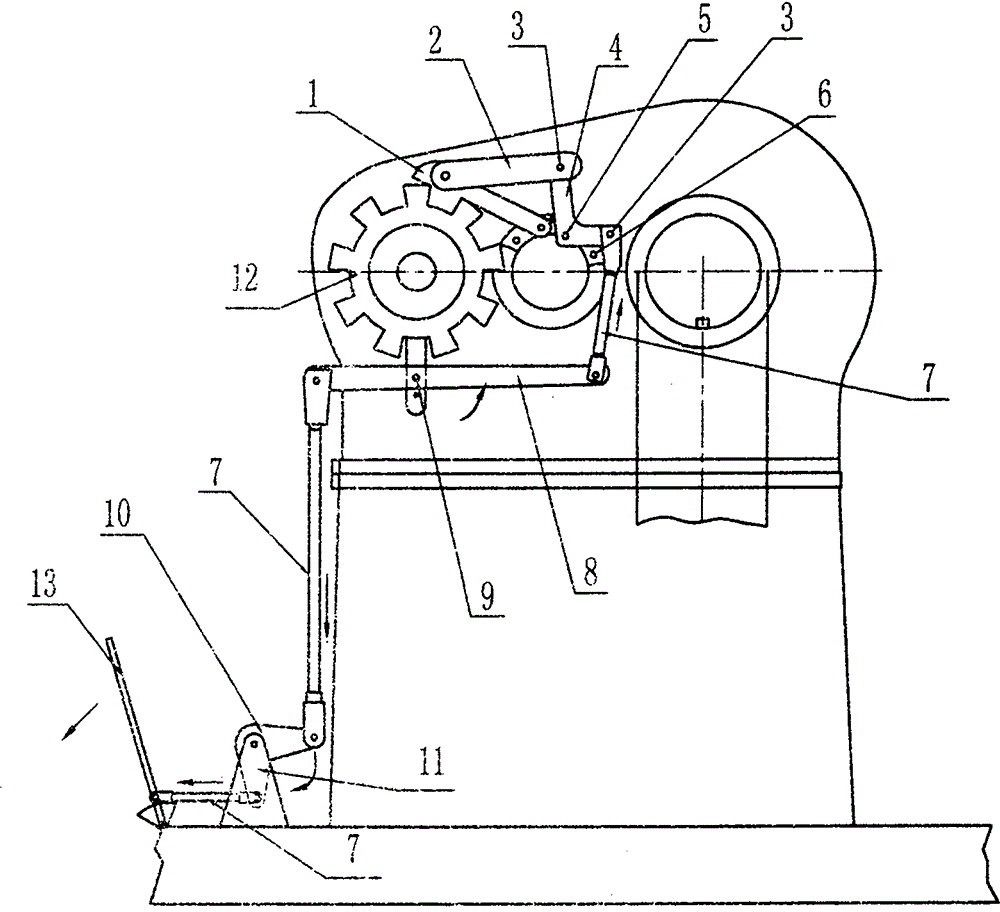

The invention discloses an aluminum armour tape winding method which comprises the following steps of enabling one end of an aluminum armour tape to penetrate through a hollow shaft, enabling one end, in the hollow shaft, of the aluminum armour tape to extend in the direction of the hollow shaft, wrenching a movable tooth section, rotating the hollow shaft to enable the hollow shaft to be aligned at a first opening, a second opening, a third opening and a fourth opening to form gaps, enabling a cable to penetrate into the hollow shaft through the gaps, closing the movable tooth section, using an auxiliary clamping rod to press and fix the aluminum armour tape and the cable in a hanging hook, then rotating an insulation crank to drive a first gear and a second gear to rotate through a rocker in an insulation barrel to further drive the hollow shaft to rotate along the axis of the hollow shaft, and tightly winding the aluminum armour tape on the periphery of the fixed cable. The aluminum armour tape winding method greatly improves applicability and safety of hot-line work, enables the hot-line work to be convenient and quick and achieves the purposes of improving power supply reliability and serving the society.

Owner:STATE GRID CORP OF CHINA +1

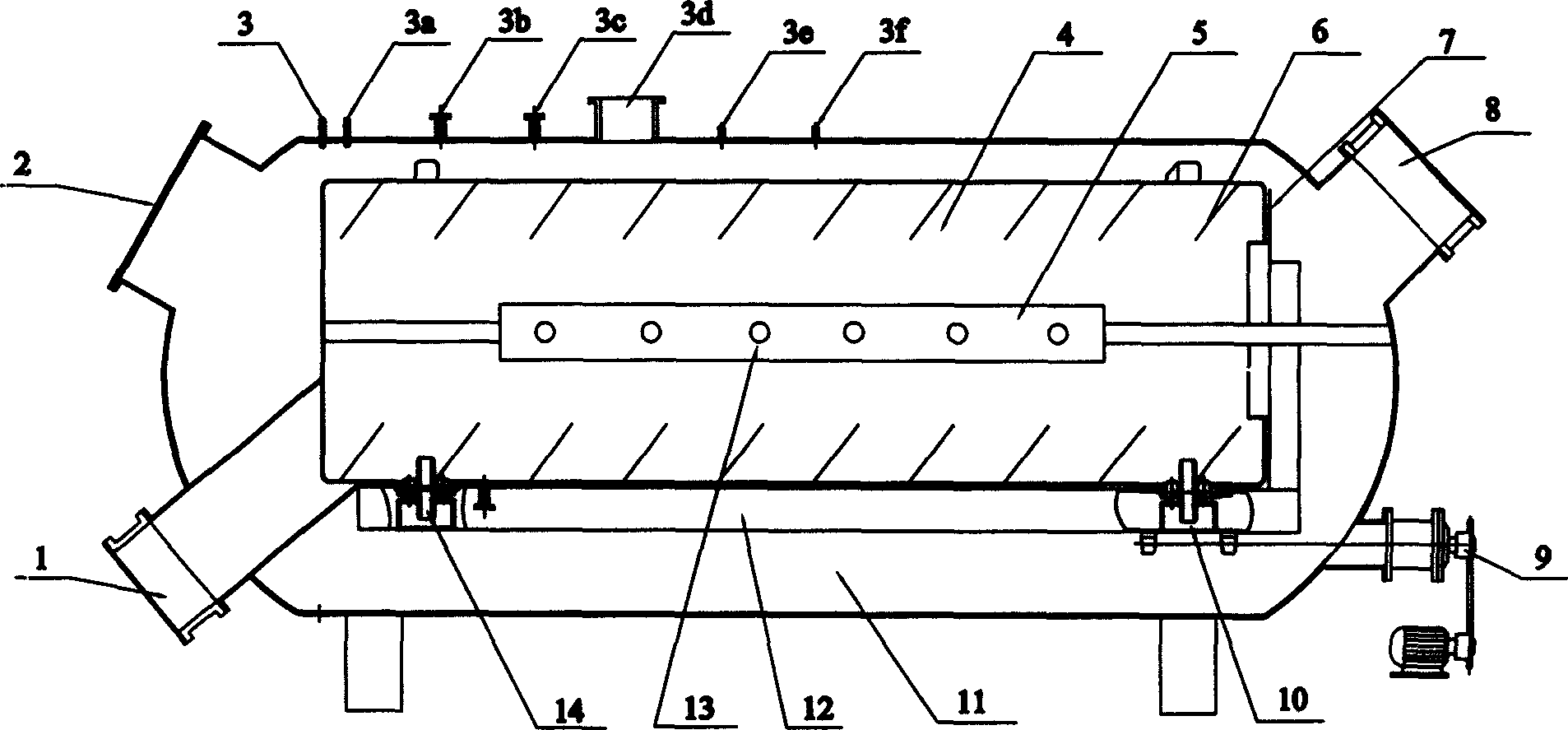

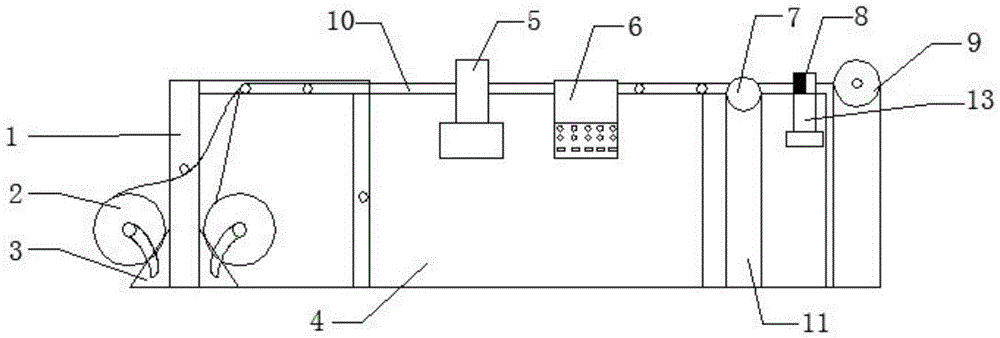

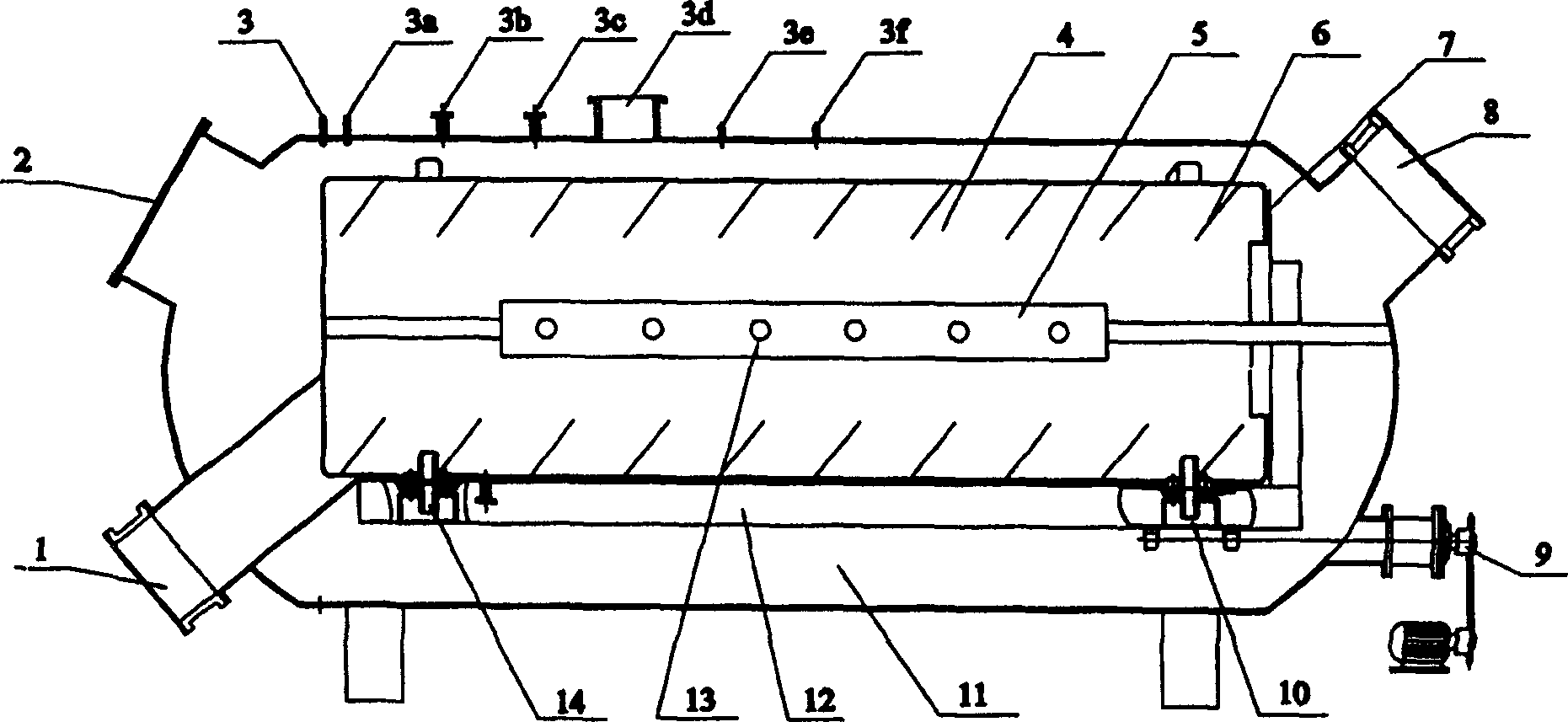

Equipment for processing tobacco leaves

InactiveCN1559312AImprove physical shapeImprove combustion effectTobacco preparationEngineeringTobacco leaf

A tobacco leaves processing apparatus for removing free nicotine, odor and stimulating substance from tobacco leaves iscomposed of a cylindrical body with drum, supporting frame and spray tube in it. Said drum is supported by the rollers on said supporting frame and is rotating on the rollers under the action of external driver. The liquid additive is sprayed onto the tobacco leaves via said spray tube.

Owner:于开平 +3

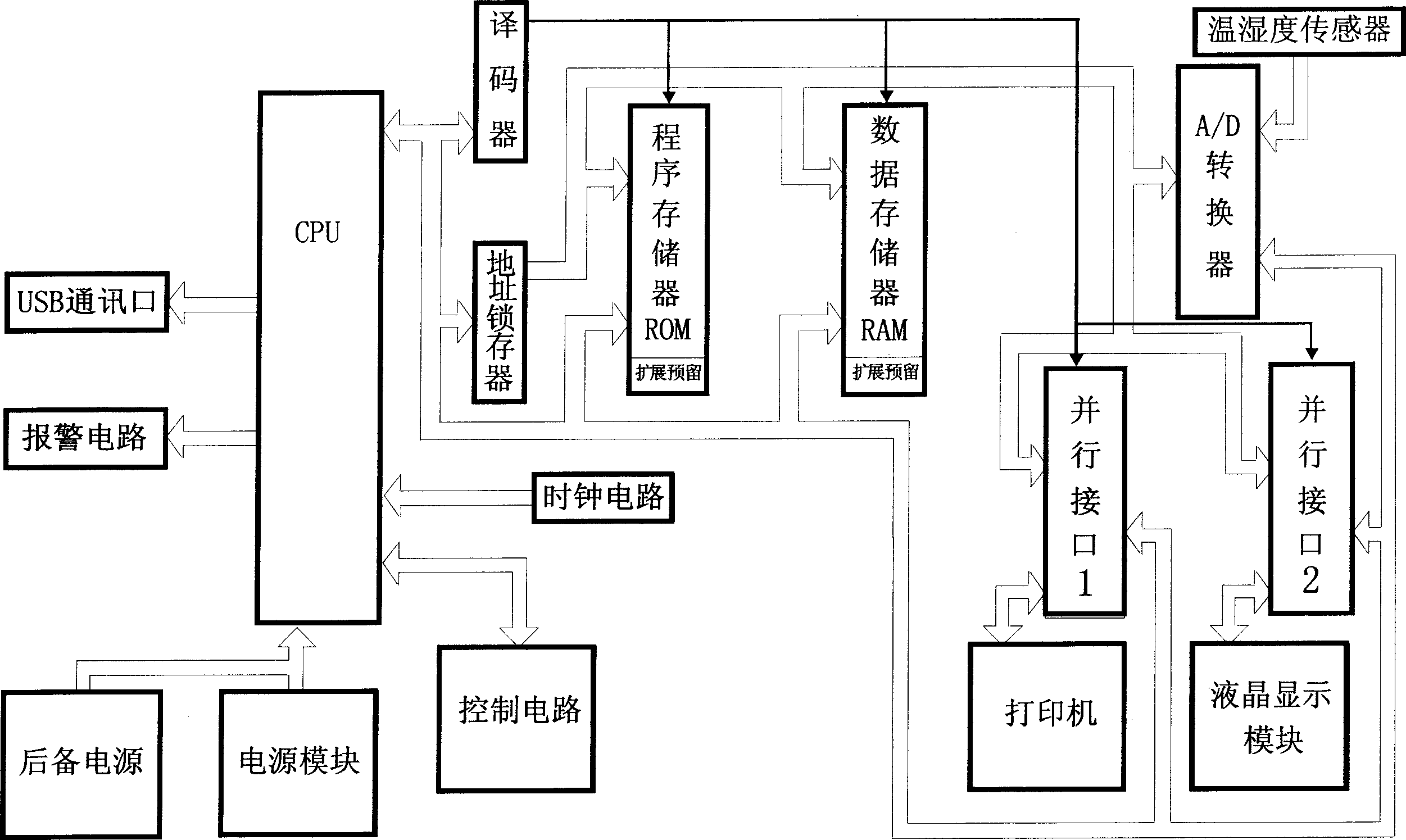

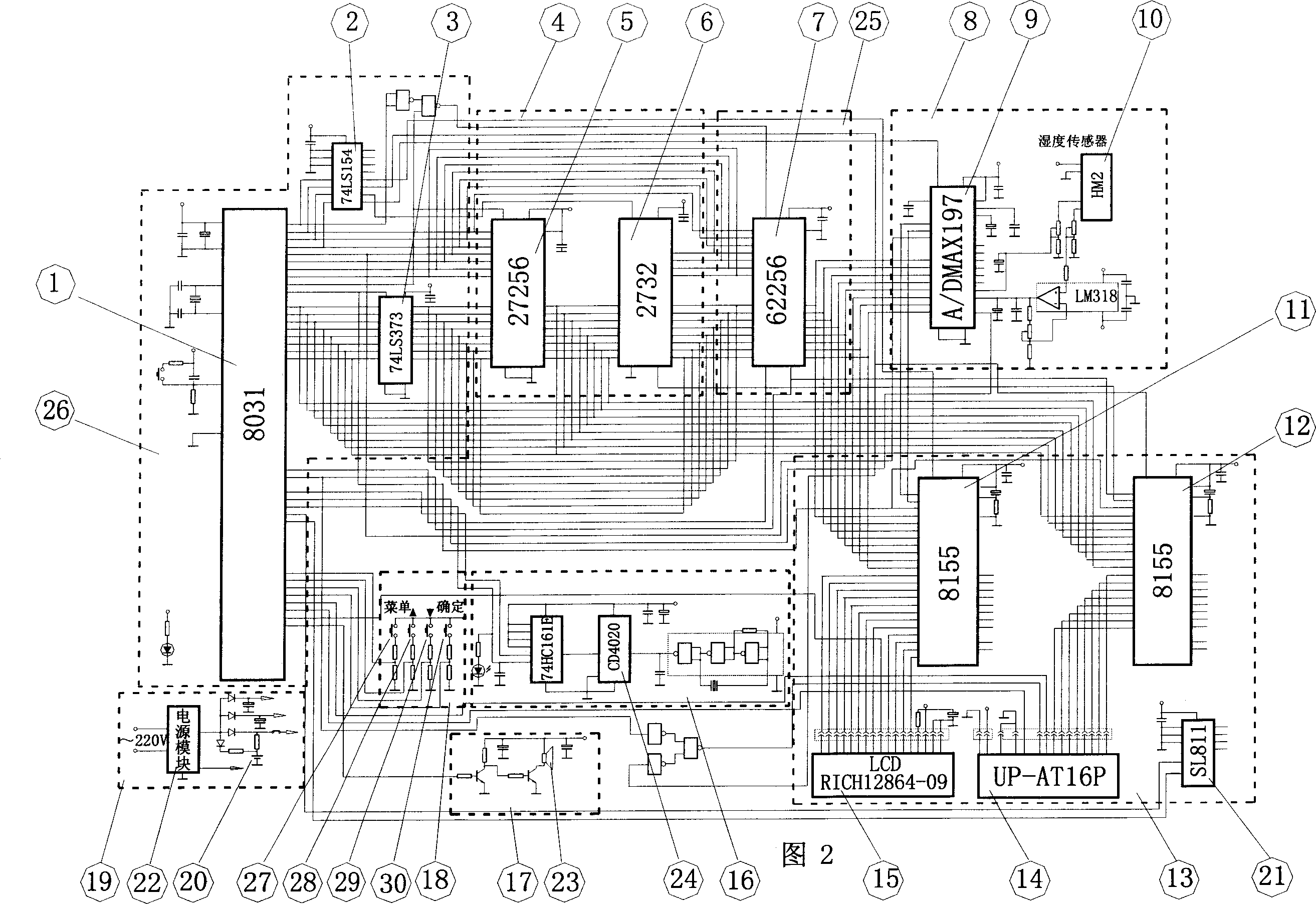

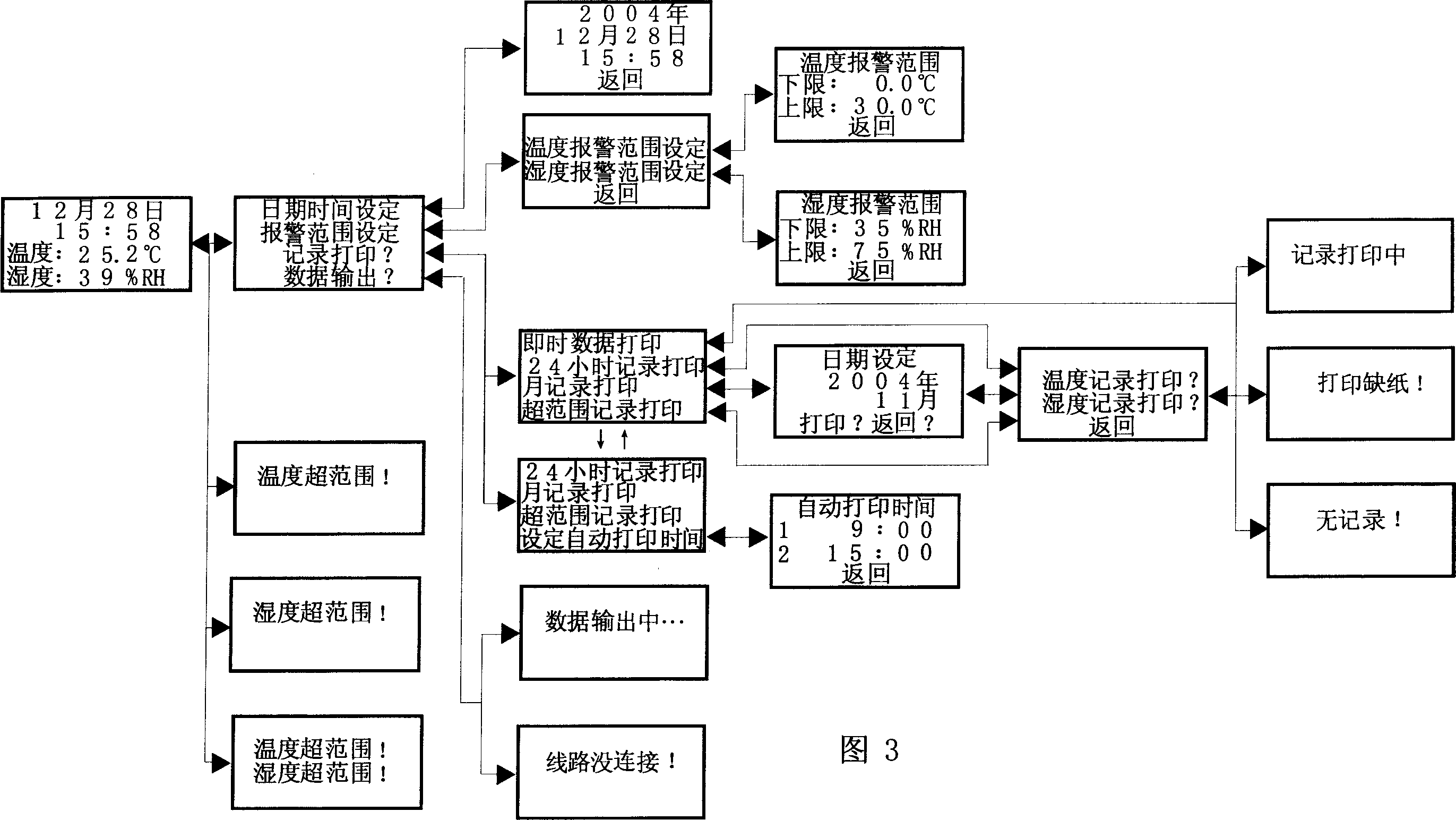

Temperature and humidity collecting recorder and making method and data management ananlysis method

InactiveCN1616930AGuarantee authenticityTo achieve safe productionRecording apparatusData acquisitionData memory

The temperature and humidity collecting recorder consists of data acquiring circuit, data memory circuit, program memory circuit, output circuit, clock control circuit, alarm circuit, functional operation control circuit and power source circuit. The temperature and humidity information, data through processing in the program memory circuit and Chinese character information are stored in the data memory. Date, time, temperature, humidity, user mark and other information are saved. The present invention combines sensor technology and computer technology and has the integral functions of data acquisition, Chinese character display, data printing and graph printing.

Owner:尹新鸣

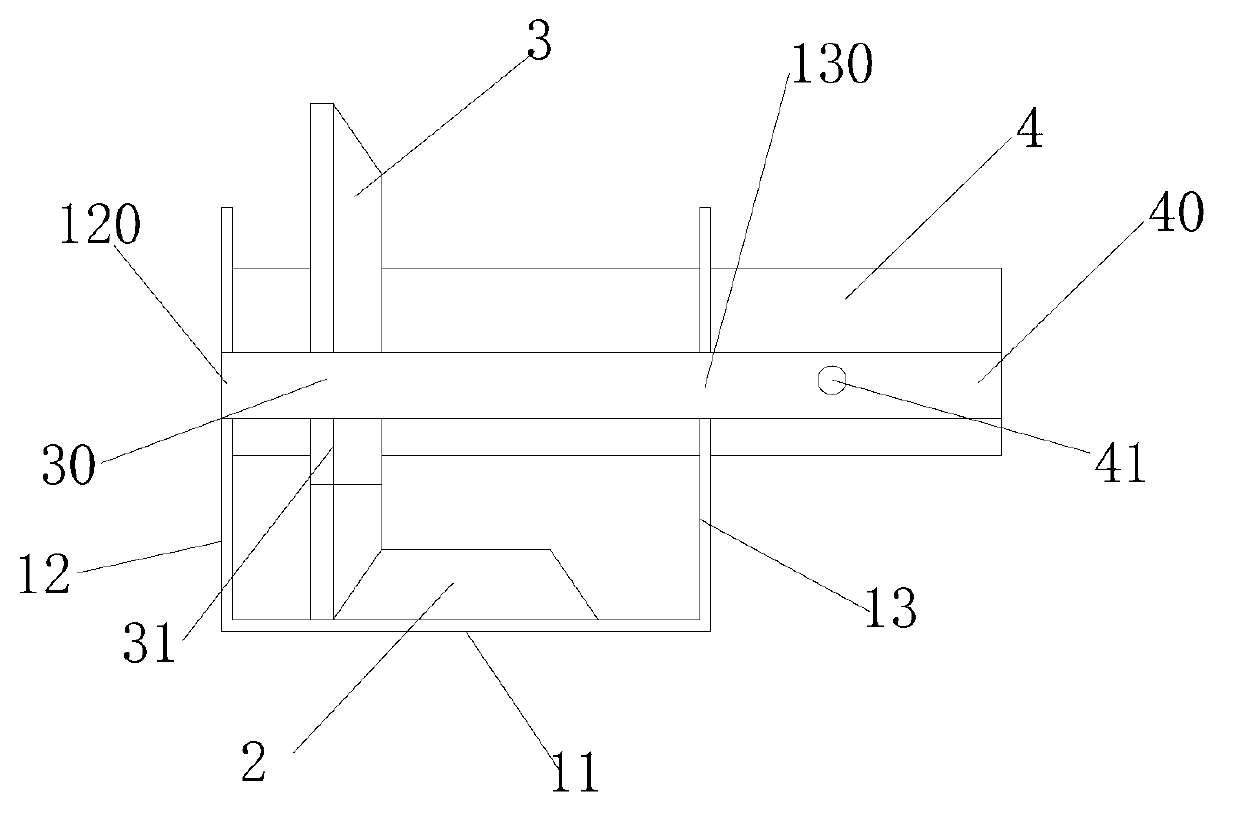

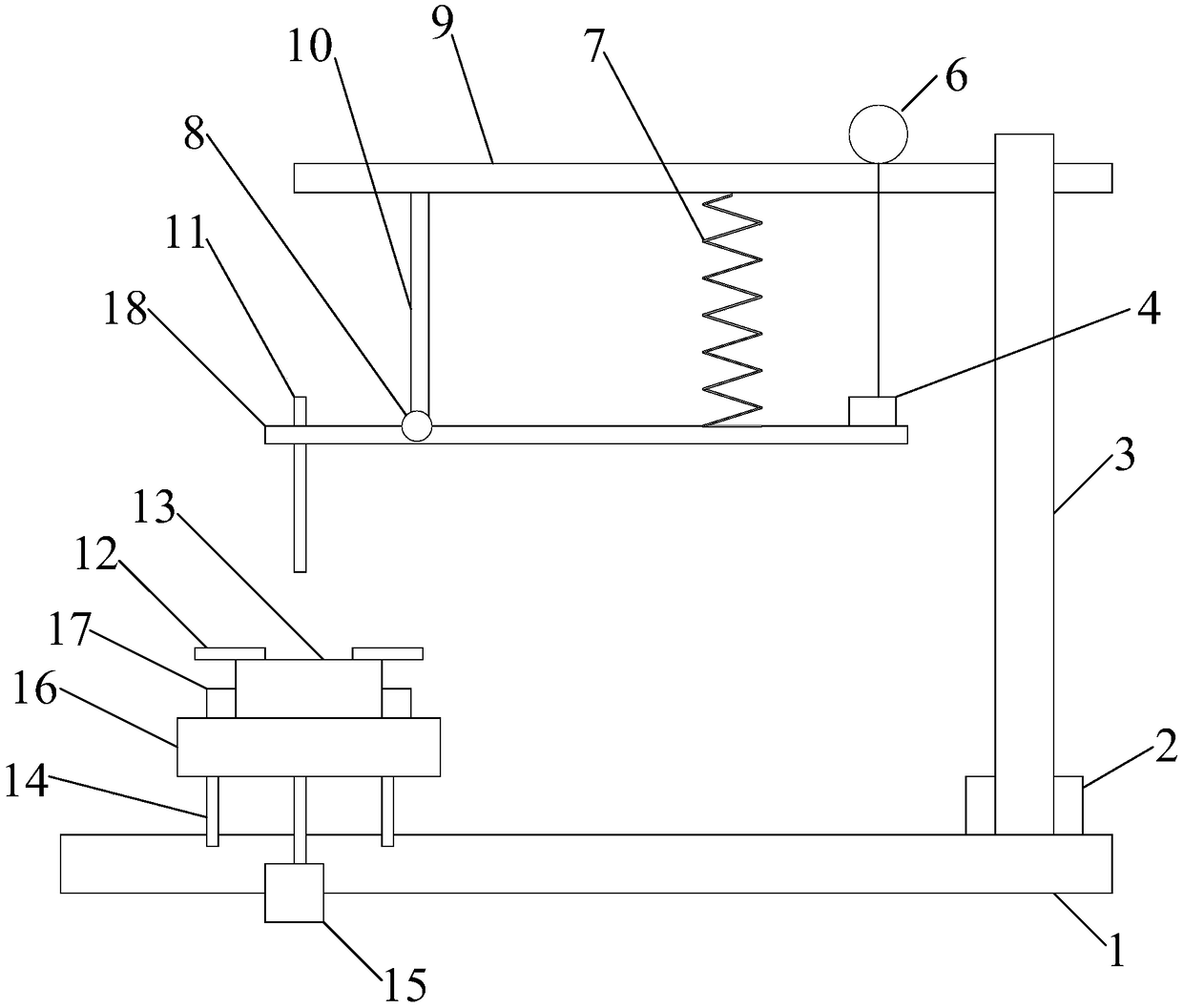

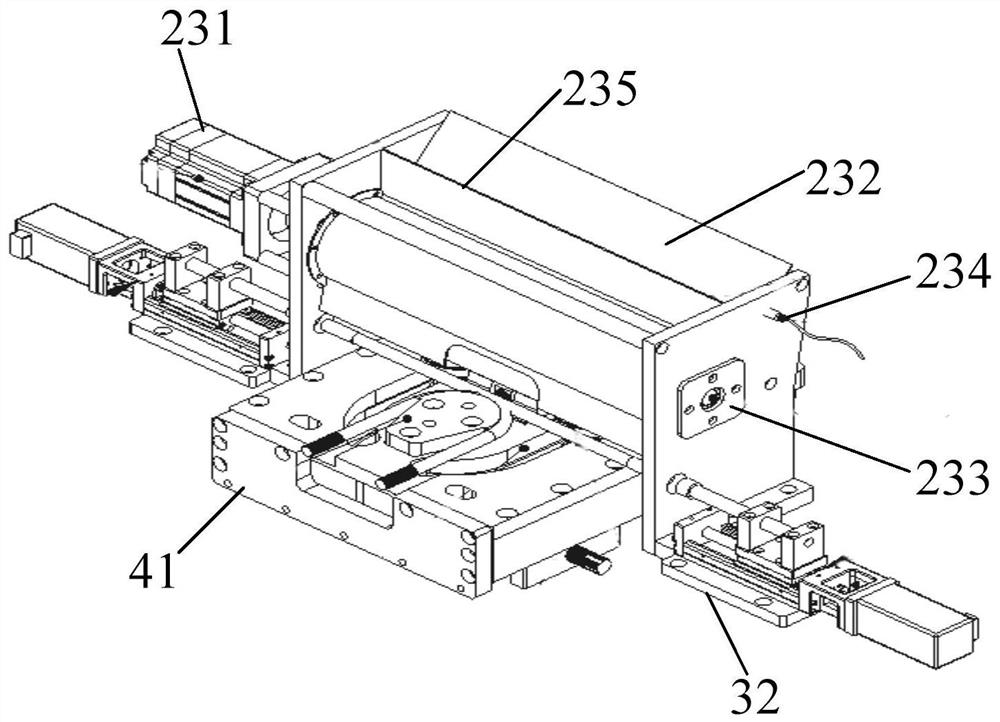

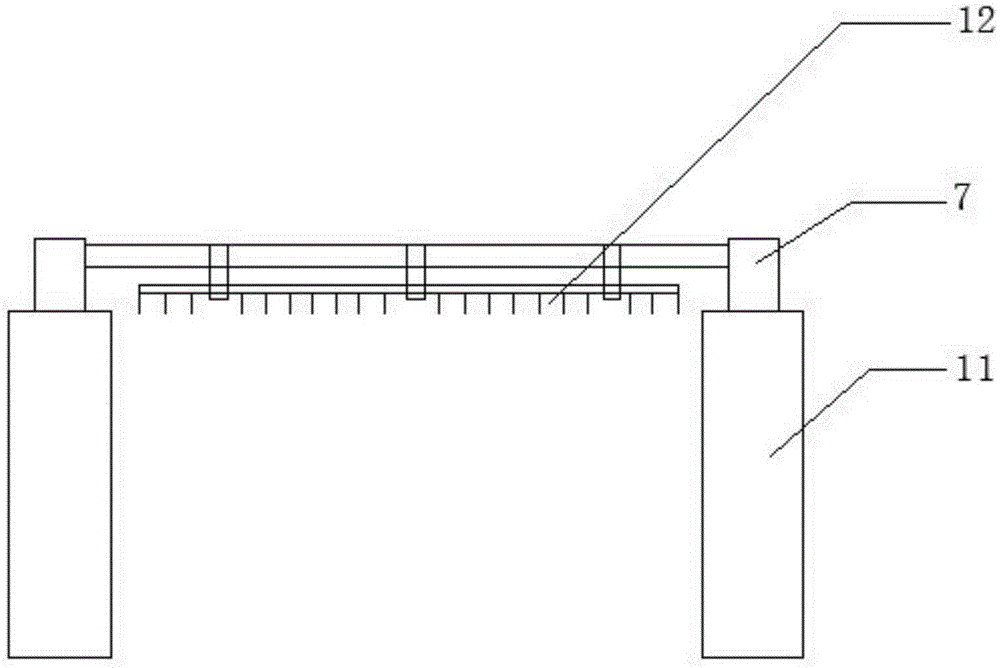

High-efficient stamping part flatness detecting device

InactiveCN108955503ASimple structureEasy to operateMechanical roughness/irregularity measurementsEngineering

The invention provides a high-efficient stamping part flatness detecting device, which is used for detecting the flatness of stamping parts in the production process of automobile parts. The high-efficient stamping part flatness detecting device includes a base, a bracket device, a detecting device and a worktable device; the bracket device and the worktable device are connected to the base; the detecting device is connected to the bracket device, and the detecting device is located above the worktable device; the detecting device comprises a dial indicator, a contact block, a spring, a connecting support rod, a measuring needle, a lever and a rotating shaft; the dial gauge passes through and is connected to a through hole of the bracket device; a probe portion of the dial indicator is connected to one end of the lever through the contact block; two ends of the spring are connected to the bracket device and the lever respectively; one end of the connecting support rod is connected to the lever through the rotating shaft; the measuring needle is connected to the bracket device; and the dial indicator, the spring, the connecting support rod, and the measuring needle are sequentiallyarranged after connection. The high-efficient stamping part flatness detecting device has a simple structure, is convenient to operate, is practical and reliable, and can improve the market competitiveness of enterprises.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

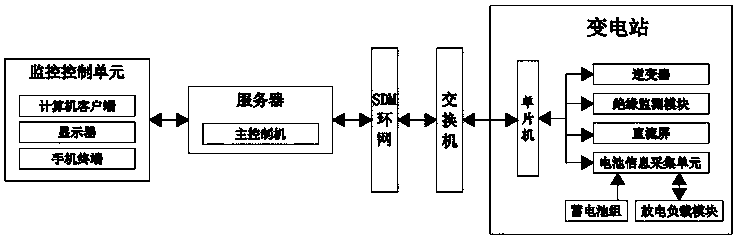

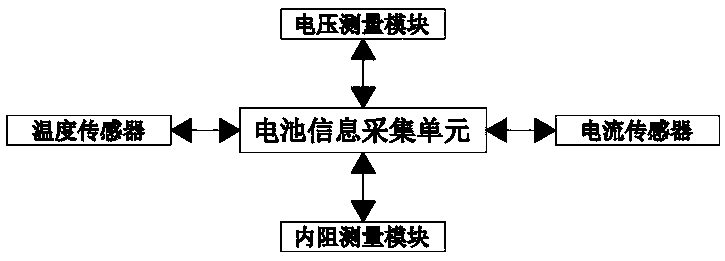

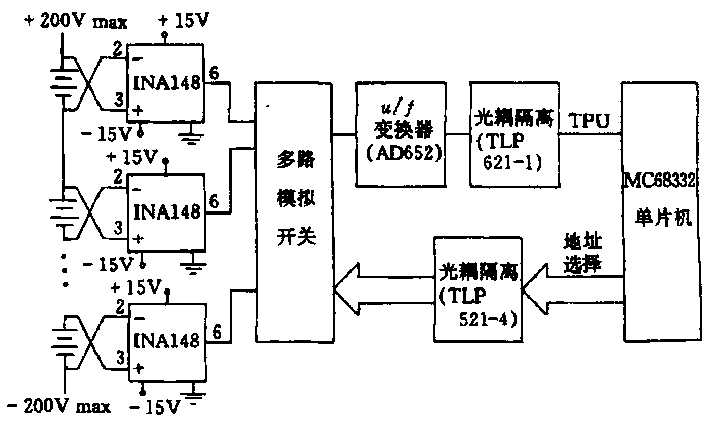

Online monitoring system for running state of transformer substation DC system

InactiveCN111007419ADetect health hazards in timePerfect alarm functionElectrical testingInternal resistanceTransformer

The invention discloses an online monitoring system for the running state of a transformer substation DC system, and relates to the technical field of substations. The system comprises a transformer substation, a switch, an SDM ring network, a server and a monitoring control unit. The transformer substation is electrically connected with the bidirectional input end of the switch through a local area network. The bidirectional output end of the switch is electrically connected with the bidirectional input end of the server through the SDM ring network. The voltage, the current and the environment temperature of a storage battery pack are monitored in real time according to the state of the storage battery pack; the voltage and the internal resistance of each single storage battery are monitored; cross comprehensive analysis is carried out on the voltage, internal resistance data and variation trend of a single storage battery in combination with a charge-discharge curve; health hidden troubles of the storage battery pack can be timely discovered and alarm prompt information can be given so that timely maintenance is facilitated, remote realization and real-time control can be realized, equipment of the transformer station DC system is enabled to be in a great working state, and objectives of safe production and working efficiency improvement can be achieved.

Owner:STATE GRID CORP OF CHINA +1

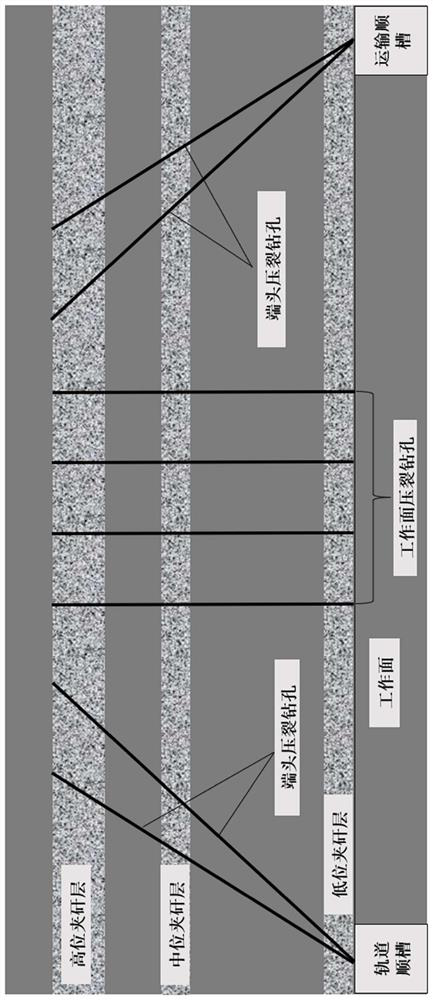

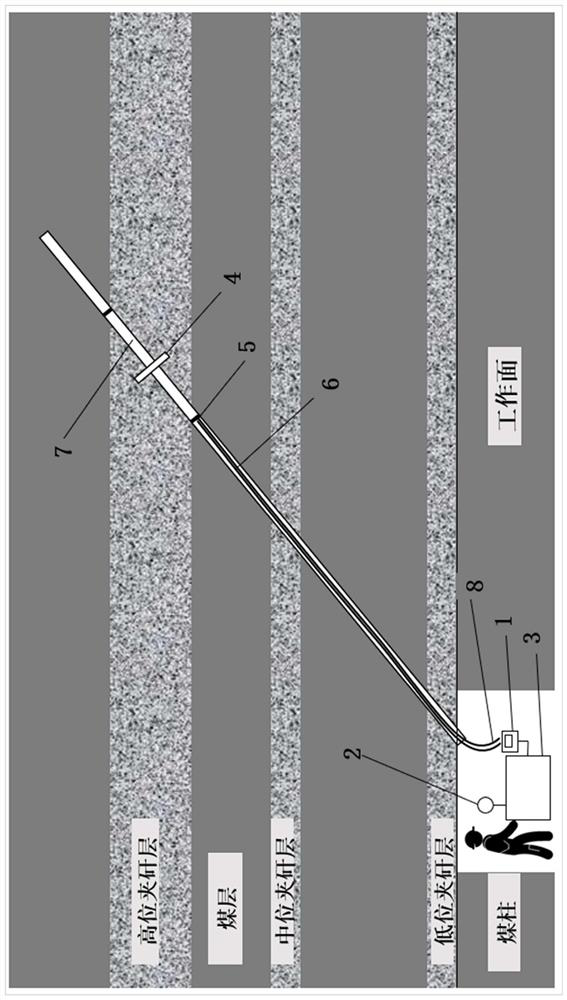

Networked presplitting technology for high-position dirt band layer of extra-thick coal seam based on hydraulic fracturing

PendingCN113982583AImprove fraudIncreased crack densityUnderground miningFluid removalMining engineeringHydraulic fracturing

The invention discloses a networked presplitting technology for a high-position dirt band layer of an extra-thick coal seam based on hydraulic fracturing. The networked presplitting technology comprises the following steps that a top coal structure of a fully mechanized caving face is observed; top coal fracturing parameters of the fully mechanized caving face are determined; fracturing drilling construction and grooving are conducted on top coal of the fully mechanized caving face; the fully mechanized caving face fracturing drill hole is subjected to drill hole sealing; high-pressure hydraulic fracturing is performed on the top coal of the fully mechanized caving face; the hydraulic fracturing effect of the fully mechanized caving face is analyzed; the step of conducting fracturing drilling construction and slotting on the top coal of the fully mechanized caving face comprises the steps that a plurality of fracturing drilling holes perpendicular to the top face of the fully mechanized caving face are formed in the top coal of the fully mechanized caving face; a plurality of fracturing drill holes which deflect towards the working face by an angle are formed in the top face of the rail gate road and the top face of the transportation gate road; and a plurality of transverse cutting grooves are formed in the part, located in the high-position dirt band layer, of the fracturing drill hole. Therefore, the high-position thick and hard dirt band layer in the coal seam can be pre-split and crushed, effective mining of the coal seam above the dirt band layer is achieved, and waste of resources is reduced.

Owner:陕西旬邑青岗坪矿业有限公司 +1

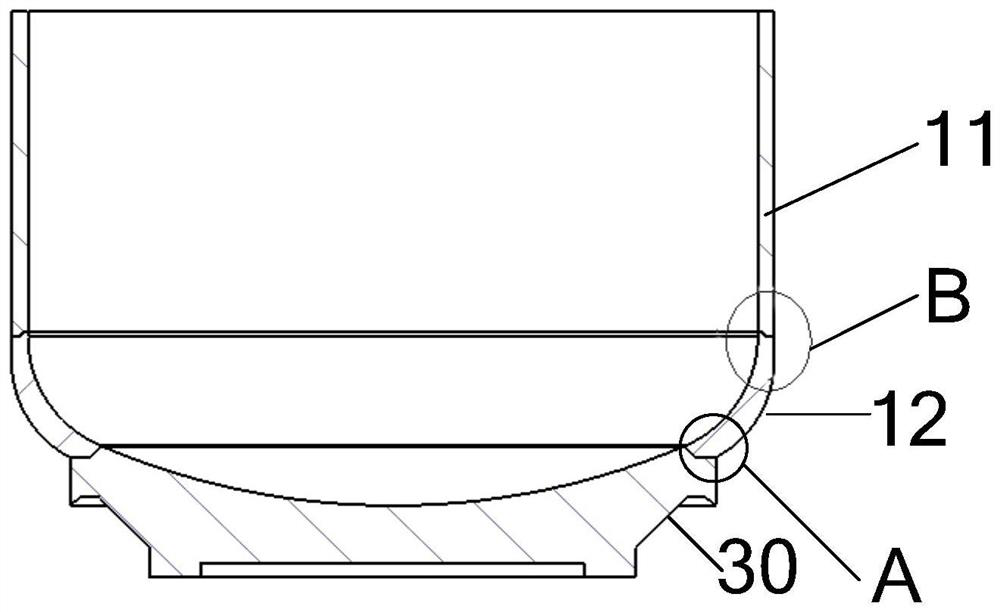

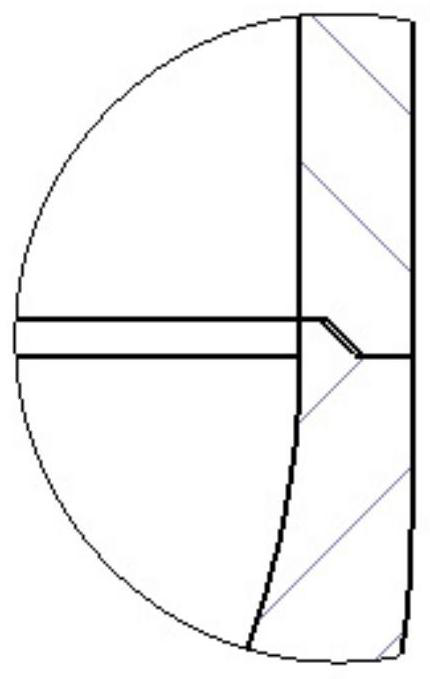

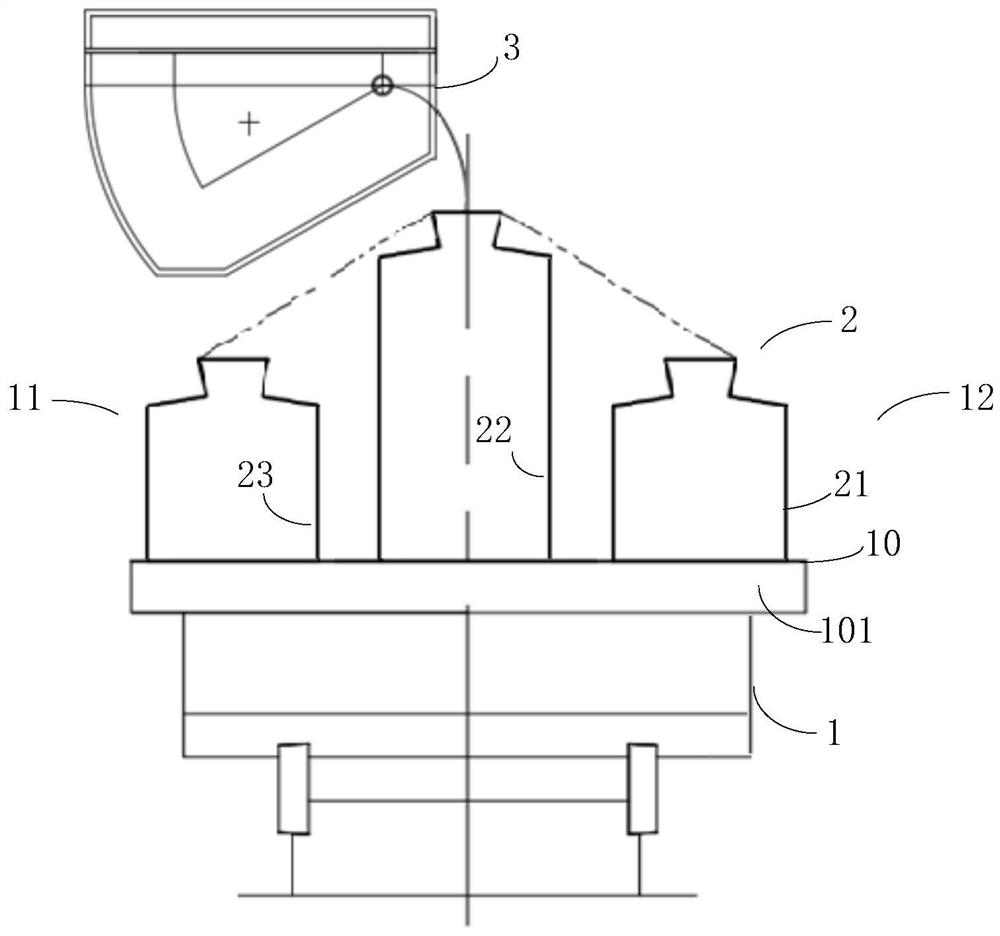

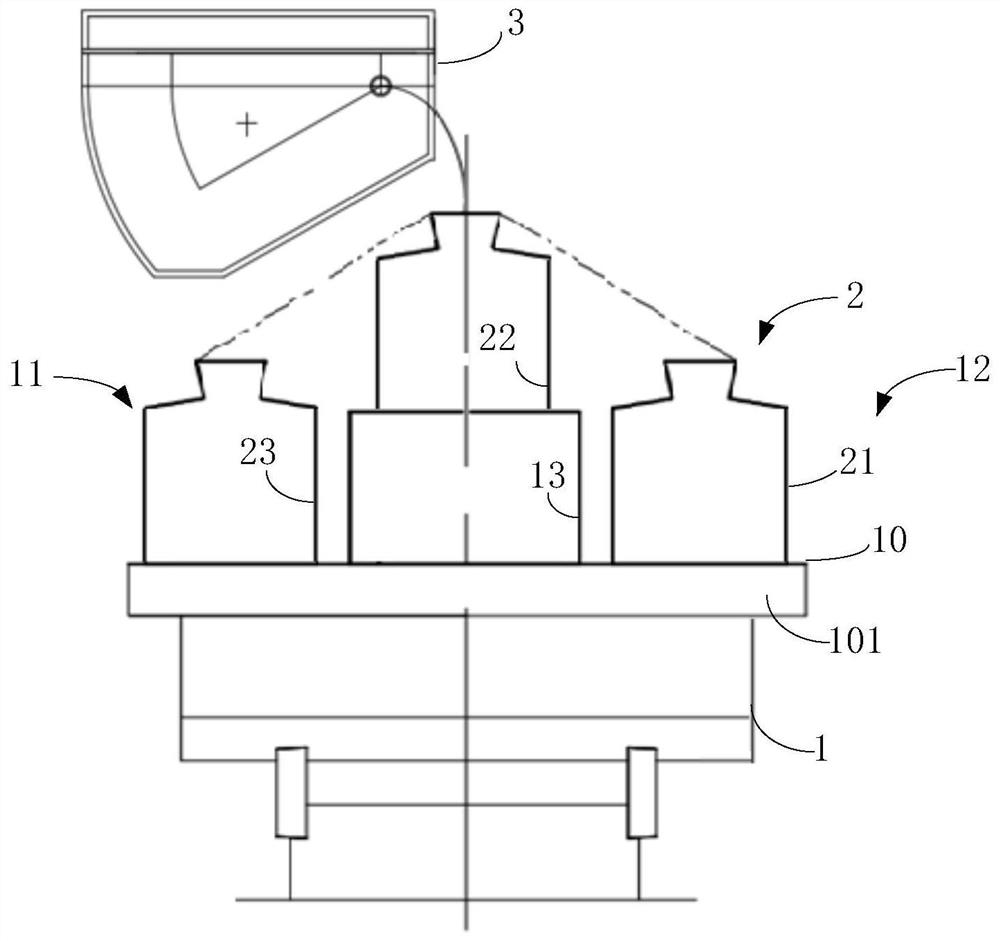

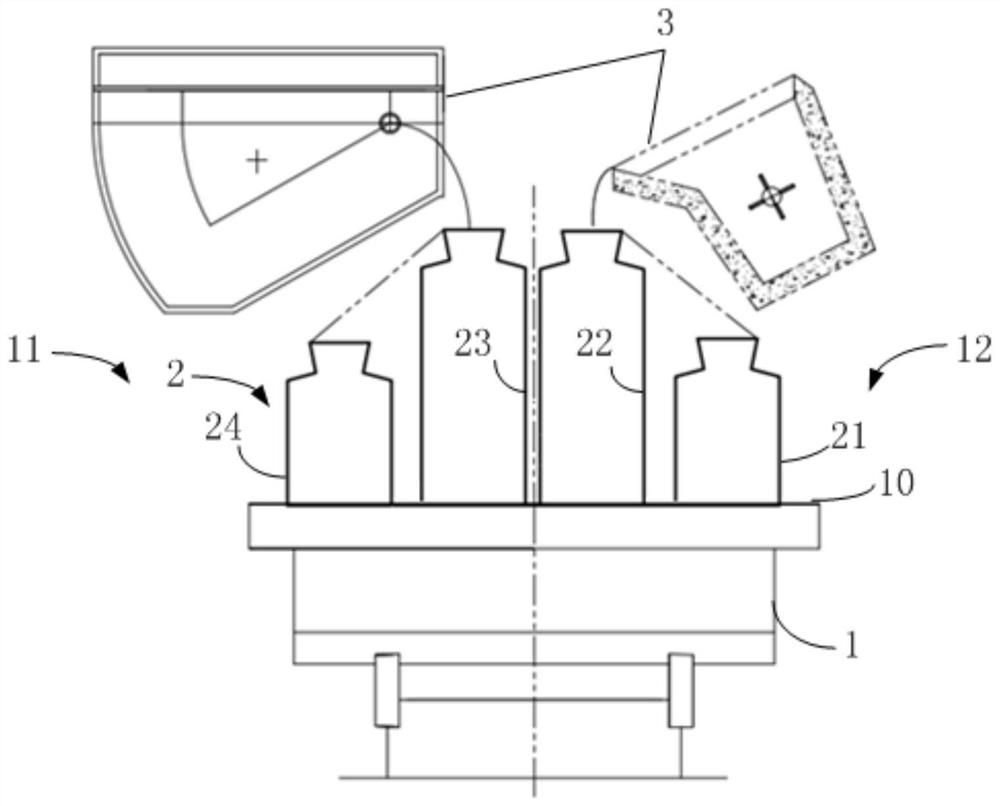

Carbon fiber bowl-shaped prefabricated body, carbon-carbon bowl body and crucible

PendingCN112195510AHigh strengthPlay a role of local enhancementPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides a carbon fiber bowl-shaped prefabricated body which is a hollow bowl-shaped body, and the diameter of an upper end opening of the carbon fiber bowl-shaped prefabricated body islarger than that of a lower end opening of the carbon fiber bowl-shaped prefabricated body. Only local vulnerable parts need to be replaced, the whole crucible does not need to be scrapped, safe production is achieved, materials are saved, and the cost is reduced.

Owner:SHANGHAI QI JIE CARBON MATERIALS

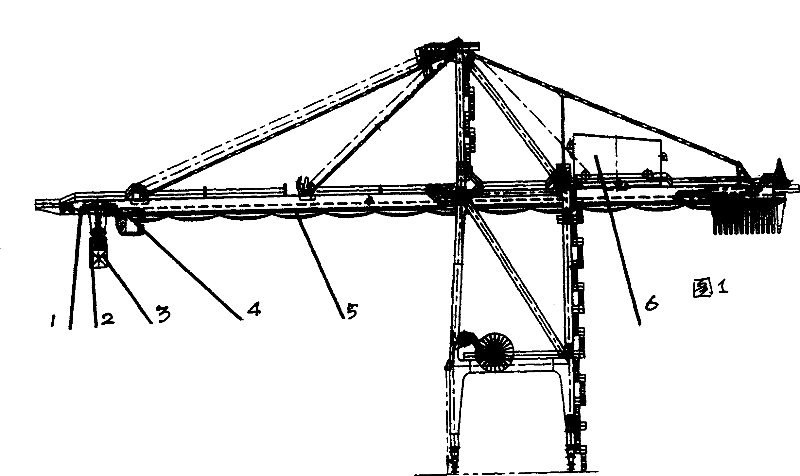

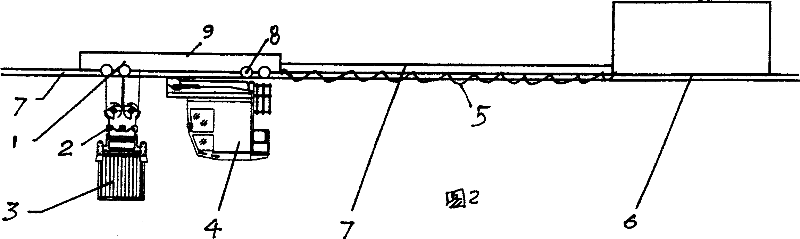

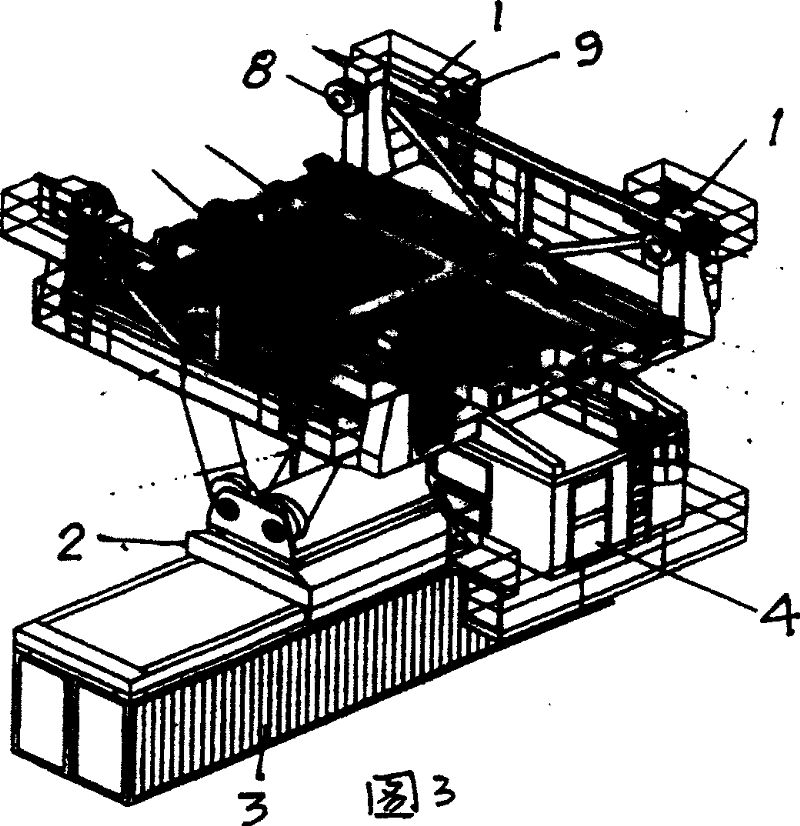

Device and control method for double speed of container bank crane vehicle

InactiveCN100337903CImprove production efficiencyImprove efficiencyLoad-engaging elementsTransverterControl circuit

This invention relates to cargotainer bank crane automobile two running speed device and method, wherein, the cargotainer has four locking signal sensors and operation bench speed selective switch to control circuit 3MJAMSC input module of control circuit. Then it is connected to communication module 217IF of control circuit SLOT3. The communication module 217IF and operation bench controls automobile haggle speed sensor connecting CPU-01. The CPU-01 connects 216IF communication module and then connects automobile converter connected to automobile motor. The invention adopts control program operation to increase speed without load.

Owner:TIANJIN PORT (GROUP) COMPANY

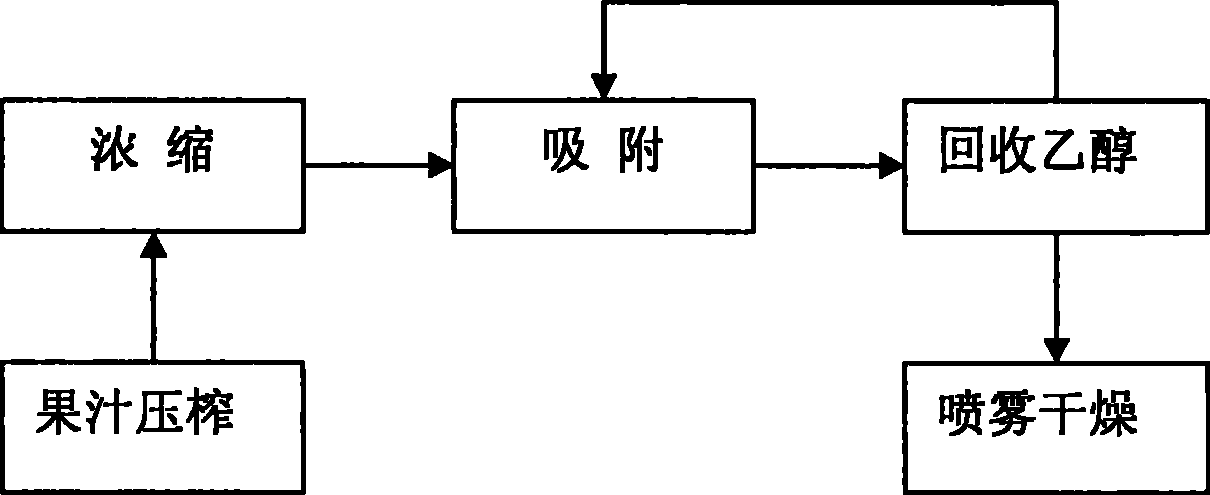

Extraction method for anthocyanin in blueberry adapted for industrial production

InactiveCN101161667BMeet environmental protection requirementsSimple processSugar derivativesSugar derivatives preparationFruit juiceElution

An extraction method for anthocyanidins from cowberry is provided, which is suitable for industrialized production and relates to an extraction method for effective components of natural plant, wherein the method includes the following procedures that: the pretreatment is carried out firstly, in which the cowberry is compressed, the juice obtained from compression is put into a condensation pot to be condensed with the Baume degree arriving at 10, then elution is carried out and the condensed juice passes through a plurality of absorbent columns successively until the juice becomes colorless,then 10-30 percent ethanol is used for the secondary elution, then the ethanol is recovered and juice is dried with spray drying technology. The technical procedures of the present invention are not only simple with low cost, but also healthy without pollution, thereby being suitable of large-scale industrialized production and capable of meeting the requirement of environmental protection the business at present.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Efficient U-shaped bolt manufacturing device

PendingCN112024759AHigh speedReduce work injuriesMetal-working feeding devicesNutsInductorHydraulic pressure

The invention provides an efficient U-shaped bolt manufacturing device which is used for automatic feeding and bending of U-shaped bolts of an automobile chassis. The manufacturing device comprises abending device, the bending device comprises a bending frame, a shaping wheel, two bending wheels, a track guide plate, a bending inductor and a hydraulic power system, the bending frame is a hollow frame body, and the shaping wheel is a sheet body with an arc groove. Arc grooves are formed in the positions, corresponding to the arc groove of the shaping wheel, of the bending wheels, the two bending wheels are connected with the hydraulic power system, and during work, the two bending wheels move along the two arc side edges of the track guide plate. The bending inductor is used for inductingwhether a bolt exists or not. According to the device, through automatic discharging, the production efficiency is improved, and the labor intensity of staff is relieved.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

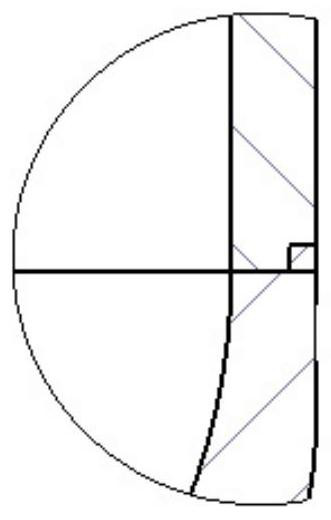

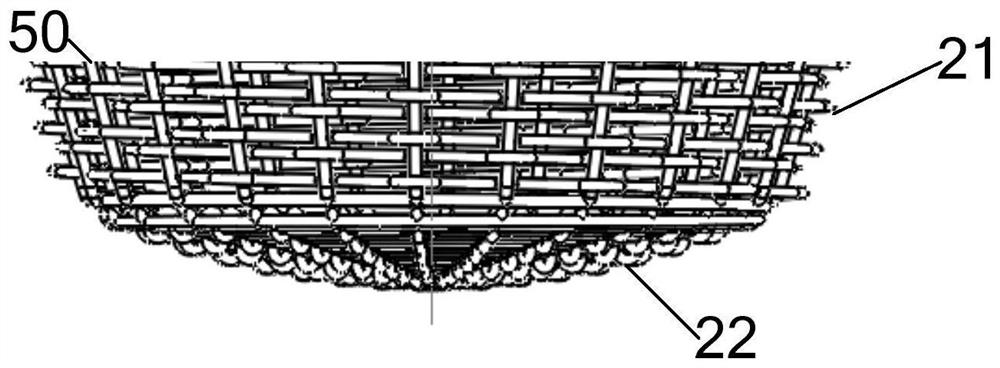

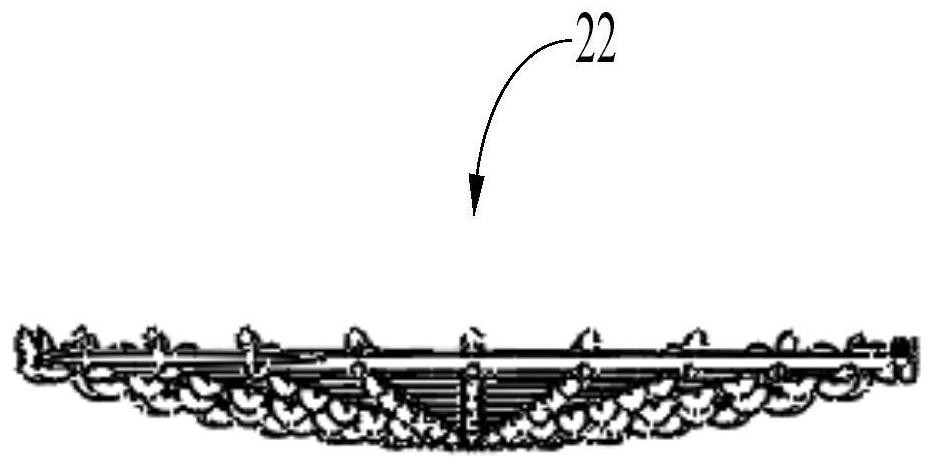

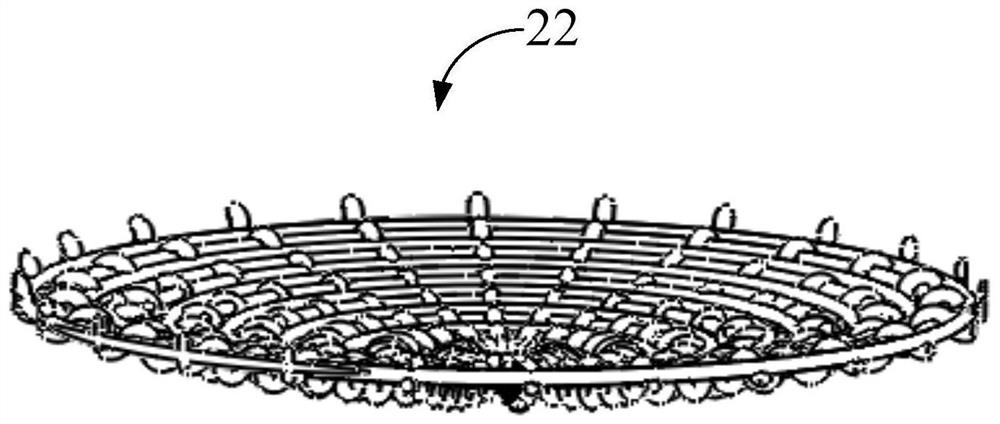

Woven bowl body prefabricated body and coating bowl body made of same

PendingCN112176402AHigh strengthPlay a role of local enhancementPolycrystalline material growthBy pulling from meltFiberCarbon fibers

The invention provides a woven bowl body prefabricated body which is used for the bottom of a crucible, namely the bottom of the crucible. The bowl body prefabricated body is a bowl-shaped net-shapedbody and is formed by weaving one or more carbon fiber ropes, and the net-shaped body of the bowl body prefabricated body is formed by aligning the one or more carbon fiber ropes in the first direction inclining by a first angle relative to a center shaft, and aligning one or more carbon fiber ropes along a second direction inclined at a second angle relative to the central shaft; wherein the second angle is the same as the first angle, and wherein the first direction and the second direction are symmetrical with respect to a central axis; or, the bowl body prefabricated body comprises a plurality of axial strips, wherein one or more carbon fiber ropes are spirally woven around the axial strips. The bowl body is woven in a crossed or spiral mode, weaving is simpler, the bowl bottom is densified, and the supporting strength of the crucible bottom is enhanced.

Owner:SHANGHAI QI JIE CARBON MATERIALS

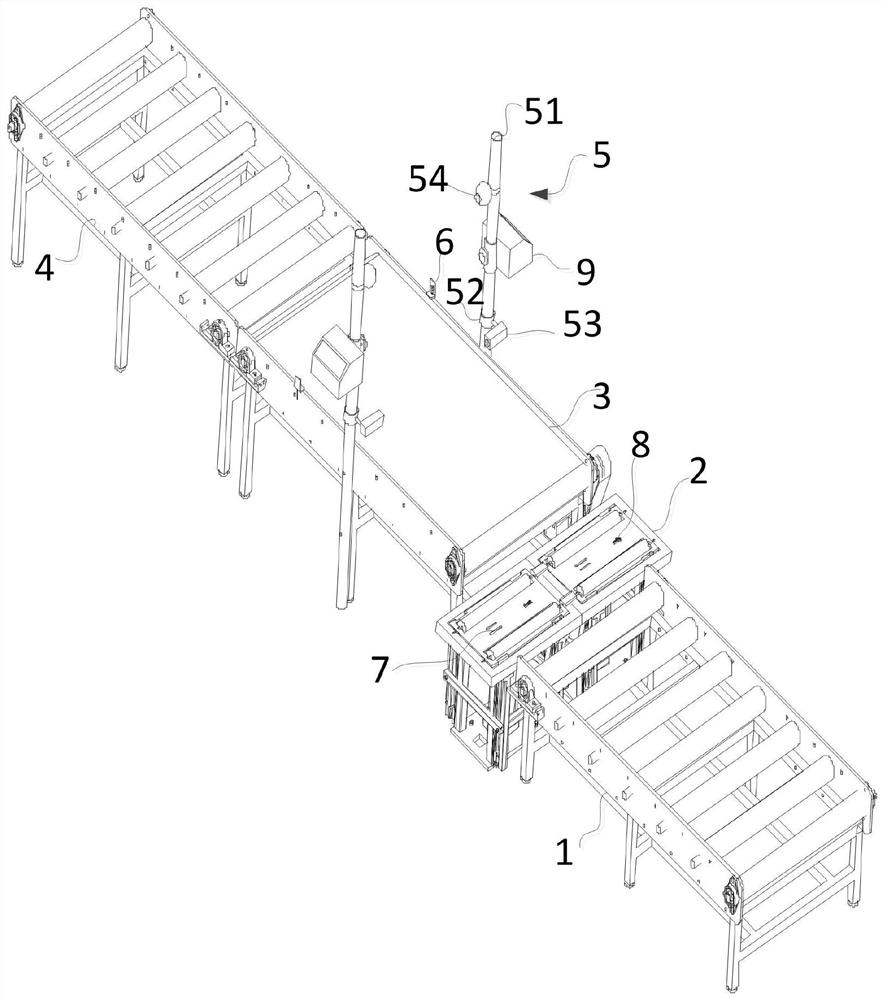

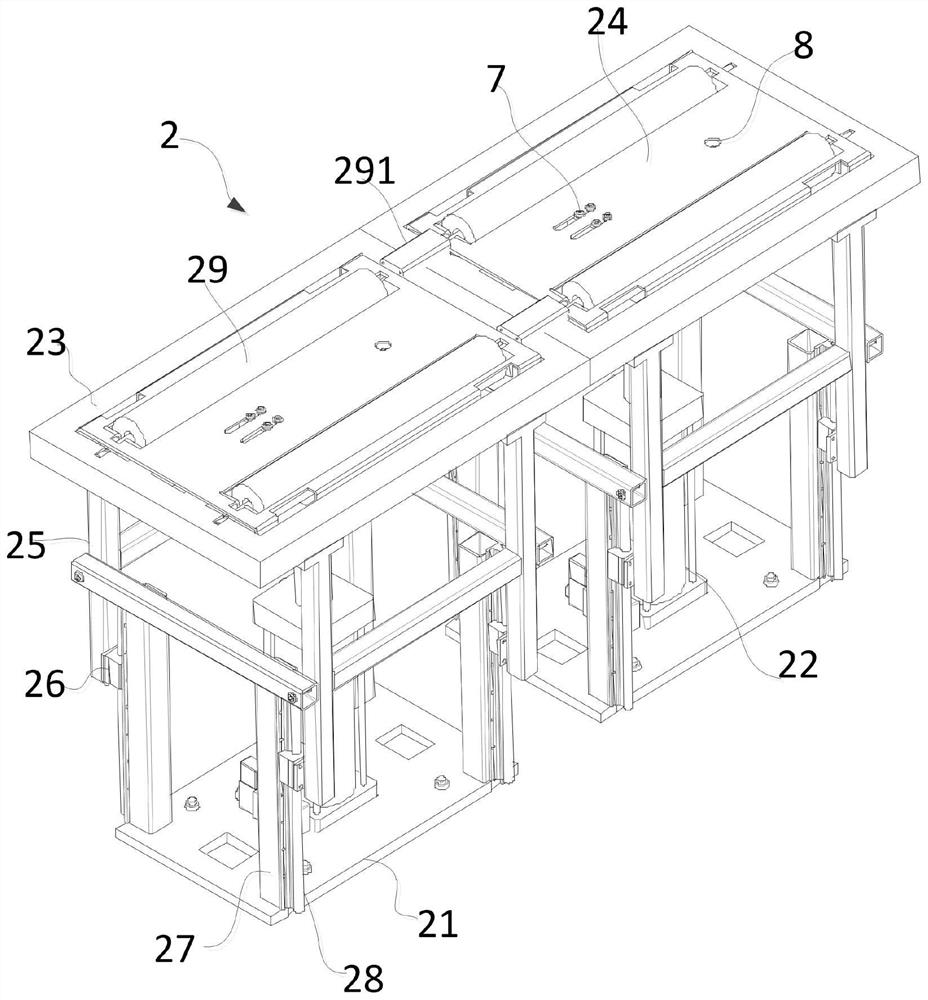

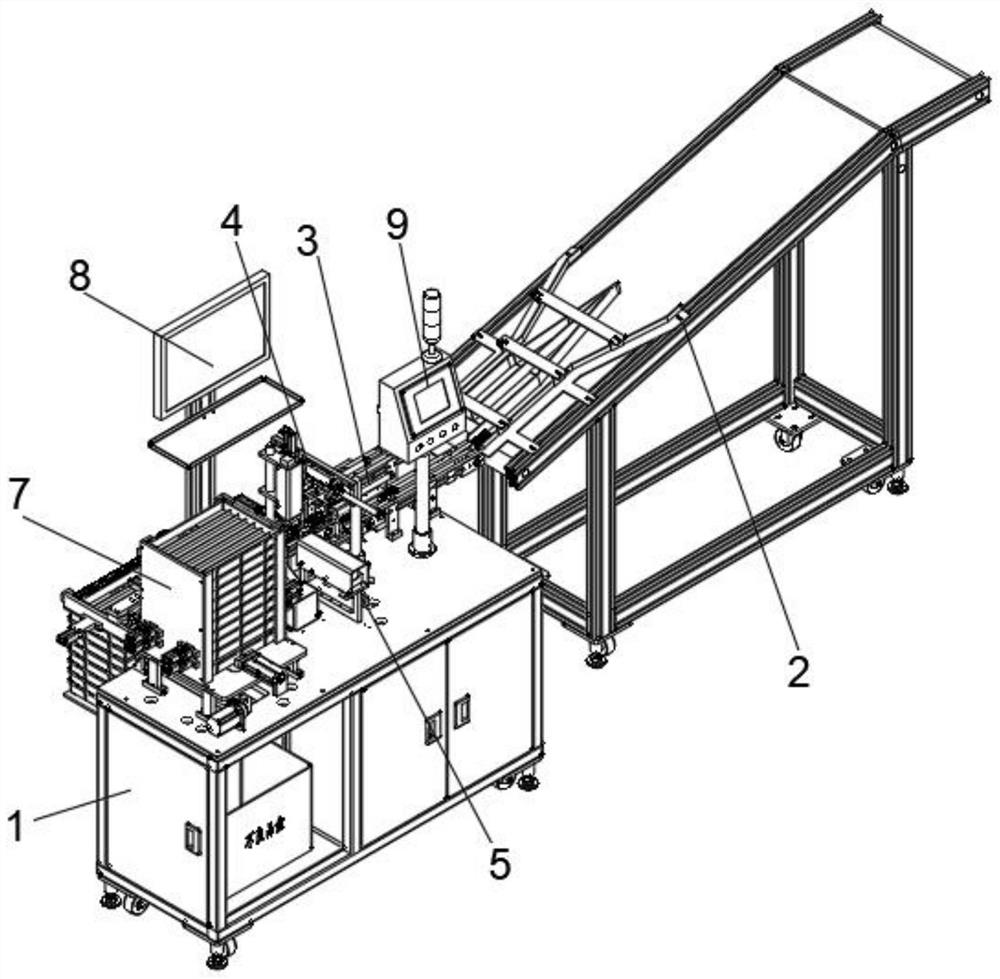

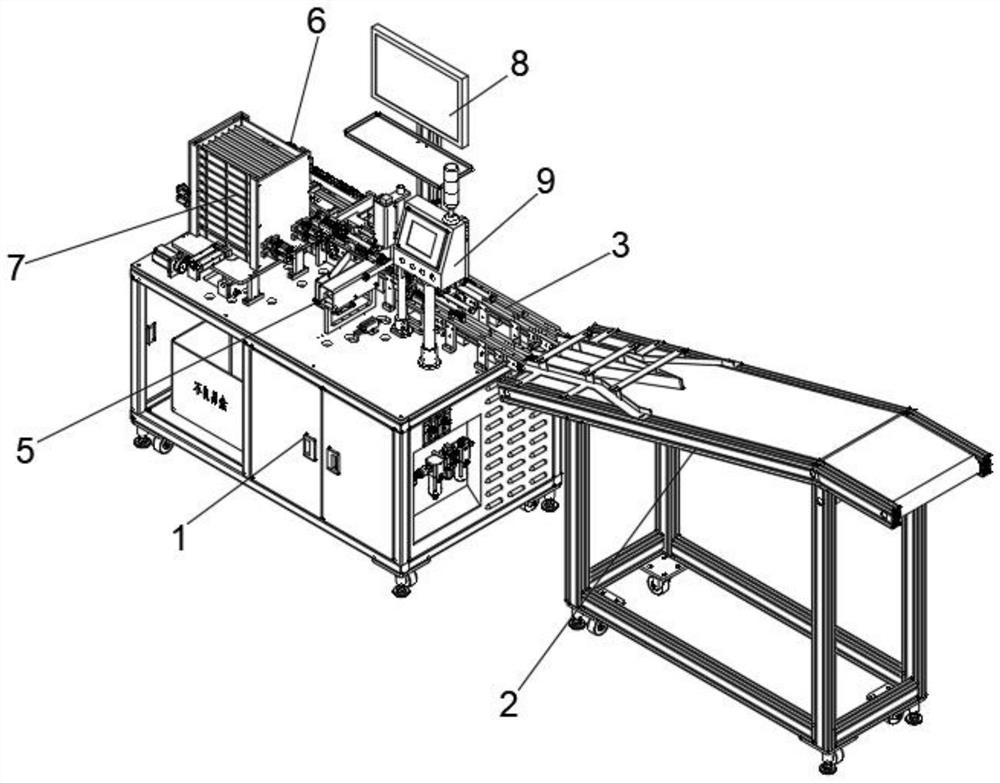

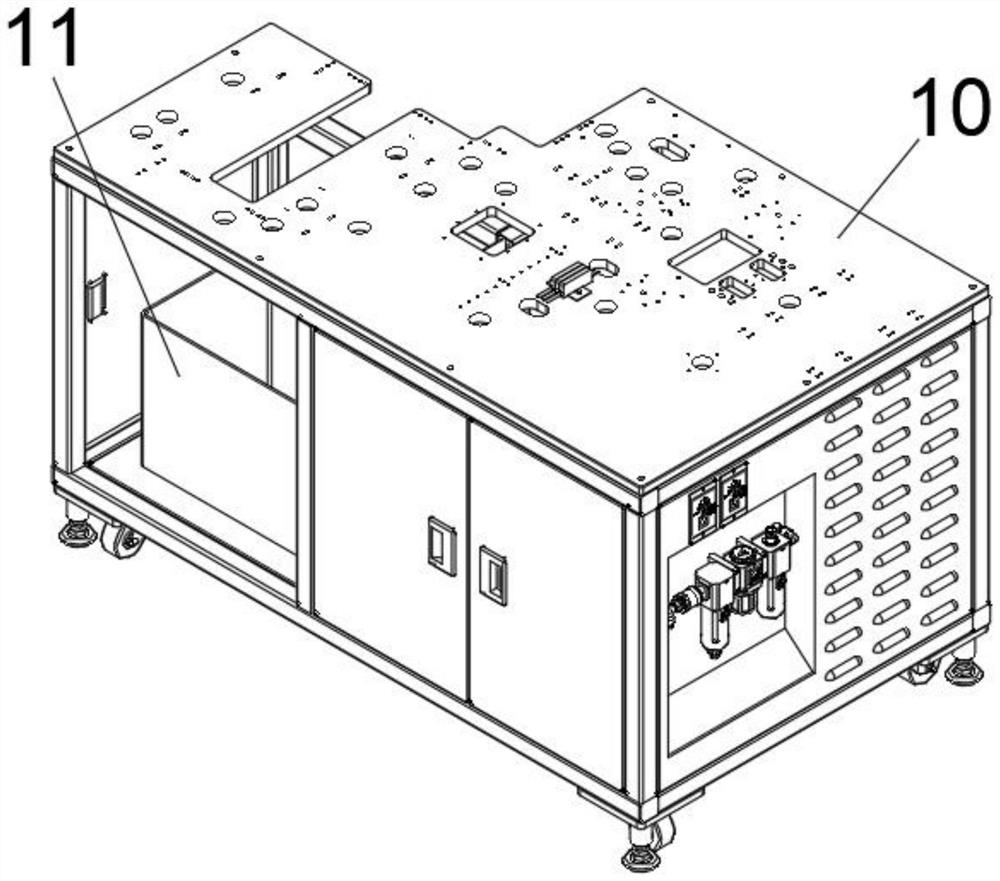

Intelligent furniture packaging production line

PendingCN111907845AReduce labor intensityTo achieve safe productionPackaging automatic controlPackaging machinesProduction lineProcess engineering

The invention belongs to the field of intelligent furniture manufacturing, and particularly relates to an intelligent furniture packaging production line. The intelligent furniture packaging production line comprises a furniture conveying device, a furniture quality inspection workbench, and a packaging conveying device which are sequentially arranged in the furniture moving direction. A monitoring code spraying device is arranged on one side of the packaging conveying device. The detection of whether parts in a box body are missed or not, a printed label, a number sign, delivery dates of thepackaging production line provided with a furniture box body, and the automatic conveying connection between the furniture box body and other devices entering a warehouse are effectively achieved. Andthe production personnel can remotely supervise and manage, or record images of the whole production process for backup and recheck, so that the purposes of safety production and reduction of the labor intensity of workers are achieved.

Owner:山东光明园迪儿童家具科技有限公司

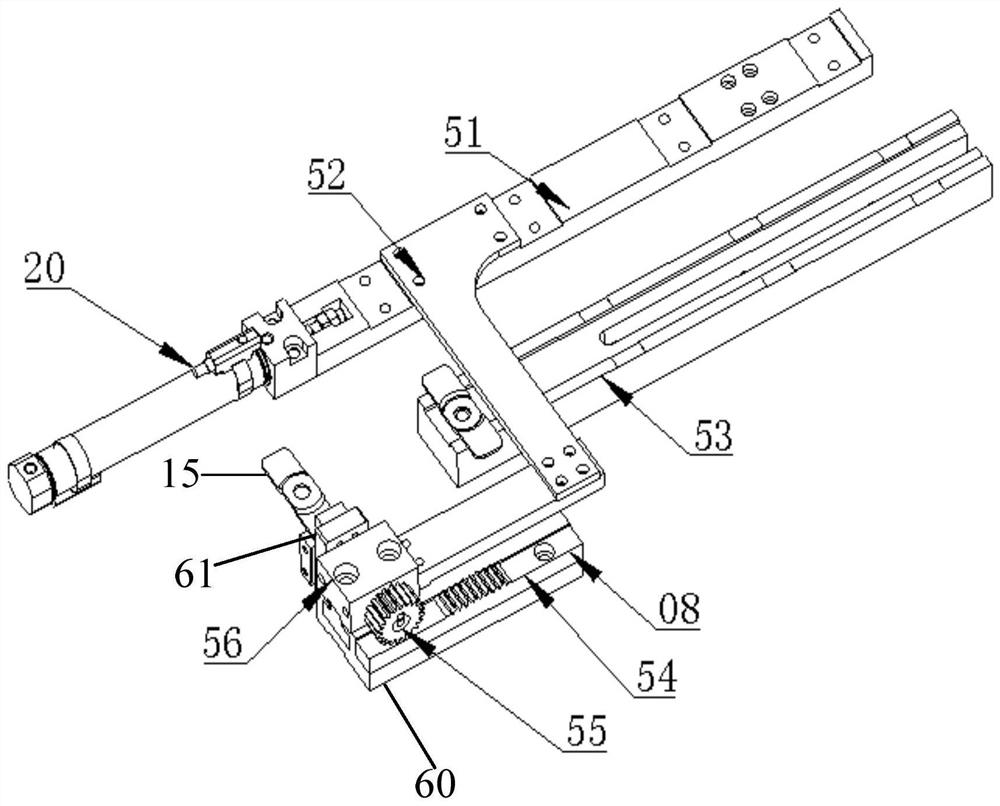

Efficient automatic spot welding device for upper longitudinal beam support

PendingCN112171035AHigh speedReduce work injuriesWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention provides an efficient automatic spot welding device for an upper longitudinal beam support. The efficient automatic spot welding device comprises an upper longitudinal beam support turnover device. The upper longitudinal beam support turnover device turns over the upper longitudinal beam support by 180 degrees. The upper longitudinal beam support turnover device comprises a limitingplate, a fixed rack, a turnover connecting block, a turnover sliding block, a turnover gear, a clamping block and a clamping air cylinder. The turnover connecting block is an L-shaped body. One end ofthe turnover connecting block is connected with a feeding air cylinder, and the other end of the turnover connecting block is arranged on one side of the limiting plate and connected with the turnover sliding block. The fixed rack is arranged on the other side of the limiting plate. The turnover gear is arranged above the fixed rack. A center shaft of the turnover gear penetrates a through hole of the turnover sliding block and then is fixedly connected with the clamping block. The clamping air cylinder is arranged on the clamping block. The efficient automatic spot welding device is reliablein structure, convenient to use, easy to maintain and high in universality, safety production is achieved, and the market competitiveness of enterprises is improved.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

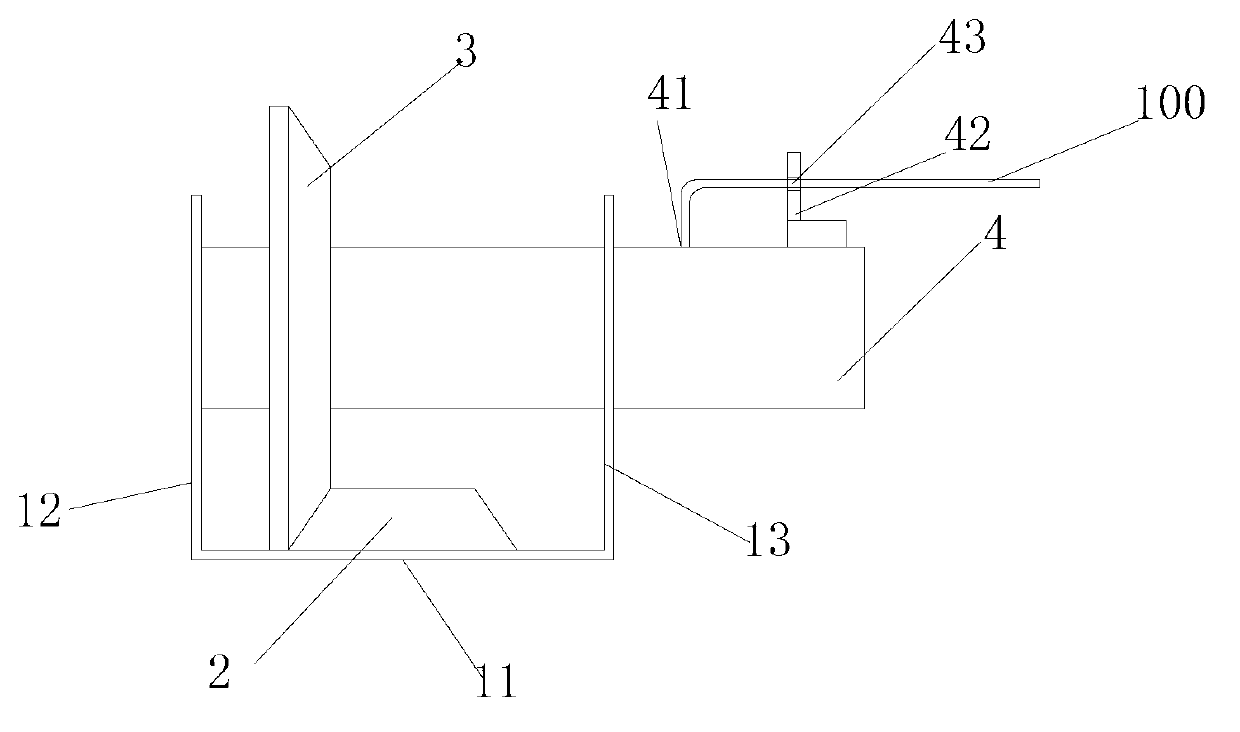

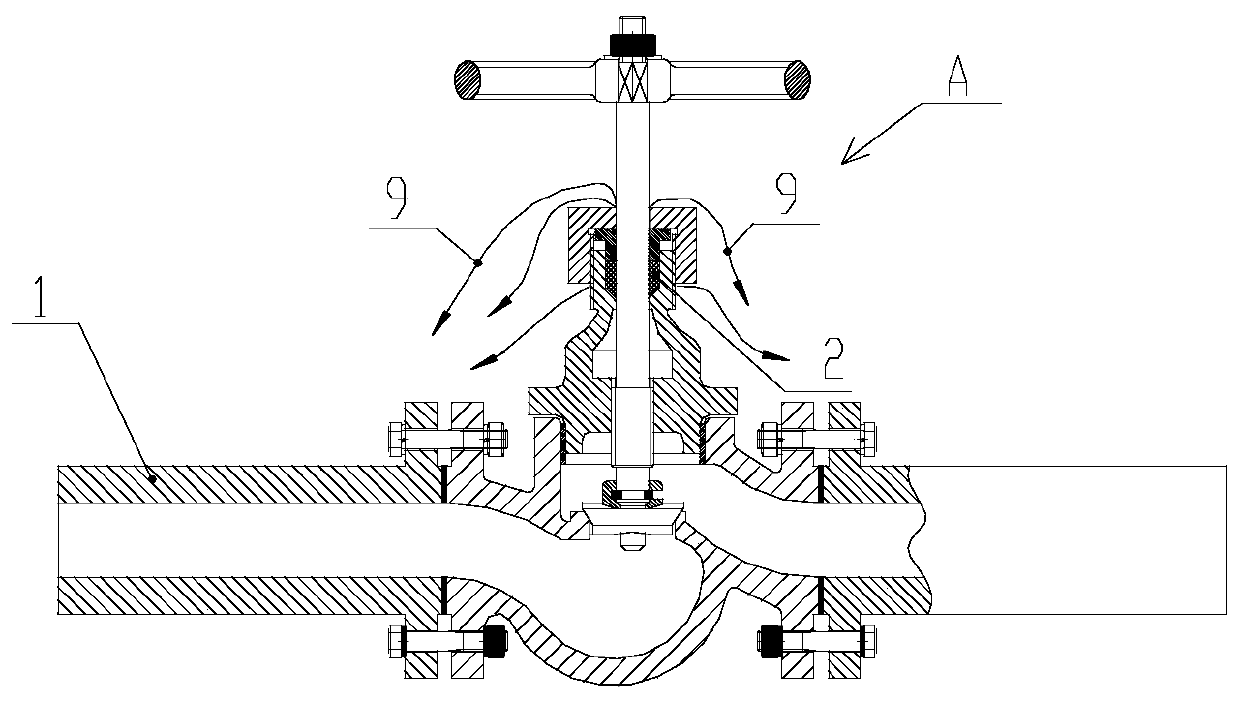

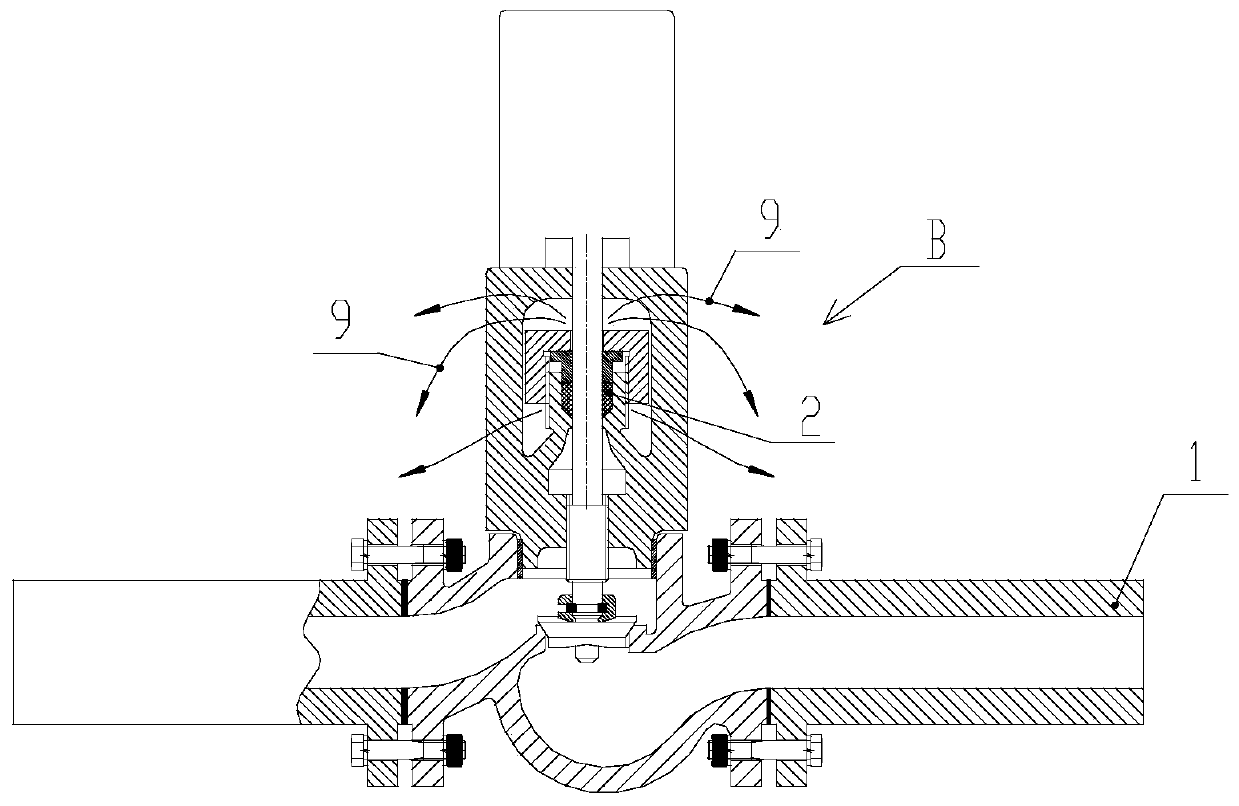

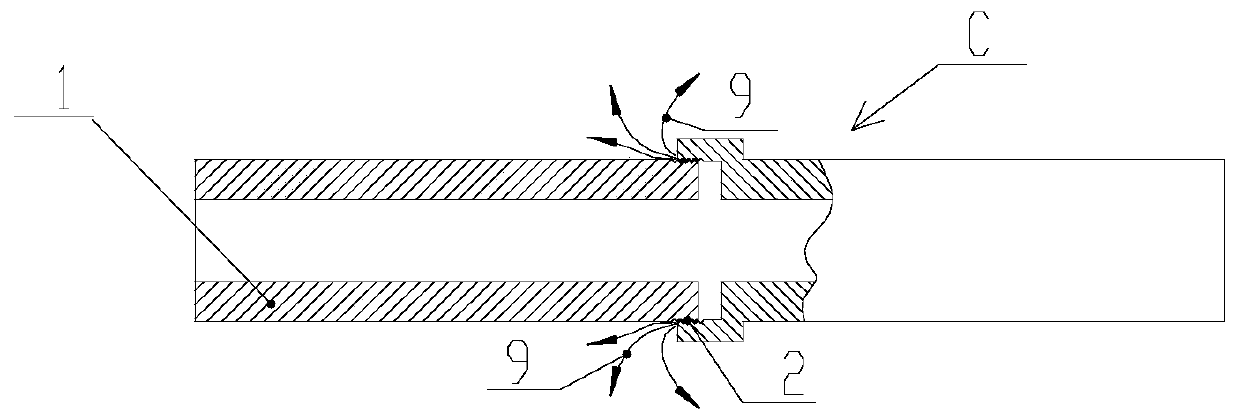

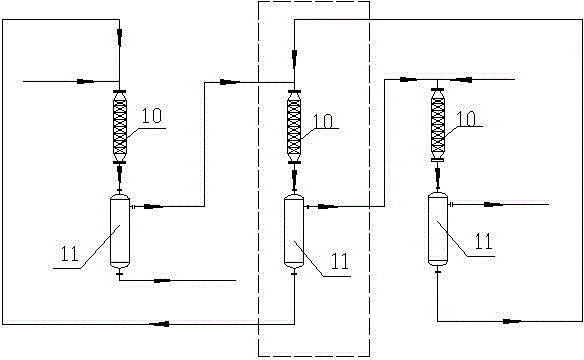

Online repair system and repair method after sealing failure of pipeline assembly

PendingCN111306395AEliminates Odors and Disease TriggersImprove production environmentPipe elementsPipeline systemsEngineeringCheck valve

The invention discloses an online repair system and repair method after sealing failure of a pipeline assembly. Each junction of a plurality of high-pressure pipelines connected end to end through connection assemblies to form a material conveying pipeline is sealed through a bag-type sealing diaphragm; the connection assemblies are located in the bag-type sealing diaphragms; an upper guide-out pipe is integrally formed on the upper part of each bag-type sealing diaphragm; a lower guide-out pipe is integrally formed on the lower part of each bag-type sealing diaphragm; an upper collection pipeis connected to a guide-out port of each upper guide-out pipe through an upper check valve; a lower collection pipe is connected to an output port of each lower guide-out pipe through a lower check valve; output ports of the upper collection pipe and the lower collection pipe are connected to a leaked material collection device separately; an output end of the leaked material collection device isconnected with the high-pressure pipeline which is nearest to the output end of the leaked material collection device through material pressing equipment; and the collected leaked materials are conveyed back into the high-pressure pipeline. The online repair system and repair method after sealing failure of the pipeline assembly does not need to stop, and is capable of repairing in the case of atemperature and a pressure, and the repair effect achieves zero leakage.

Owner:天津长瑞大通流体控制系统有限公司

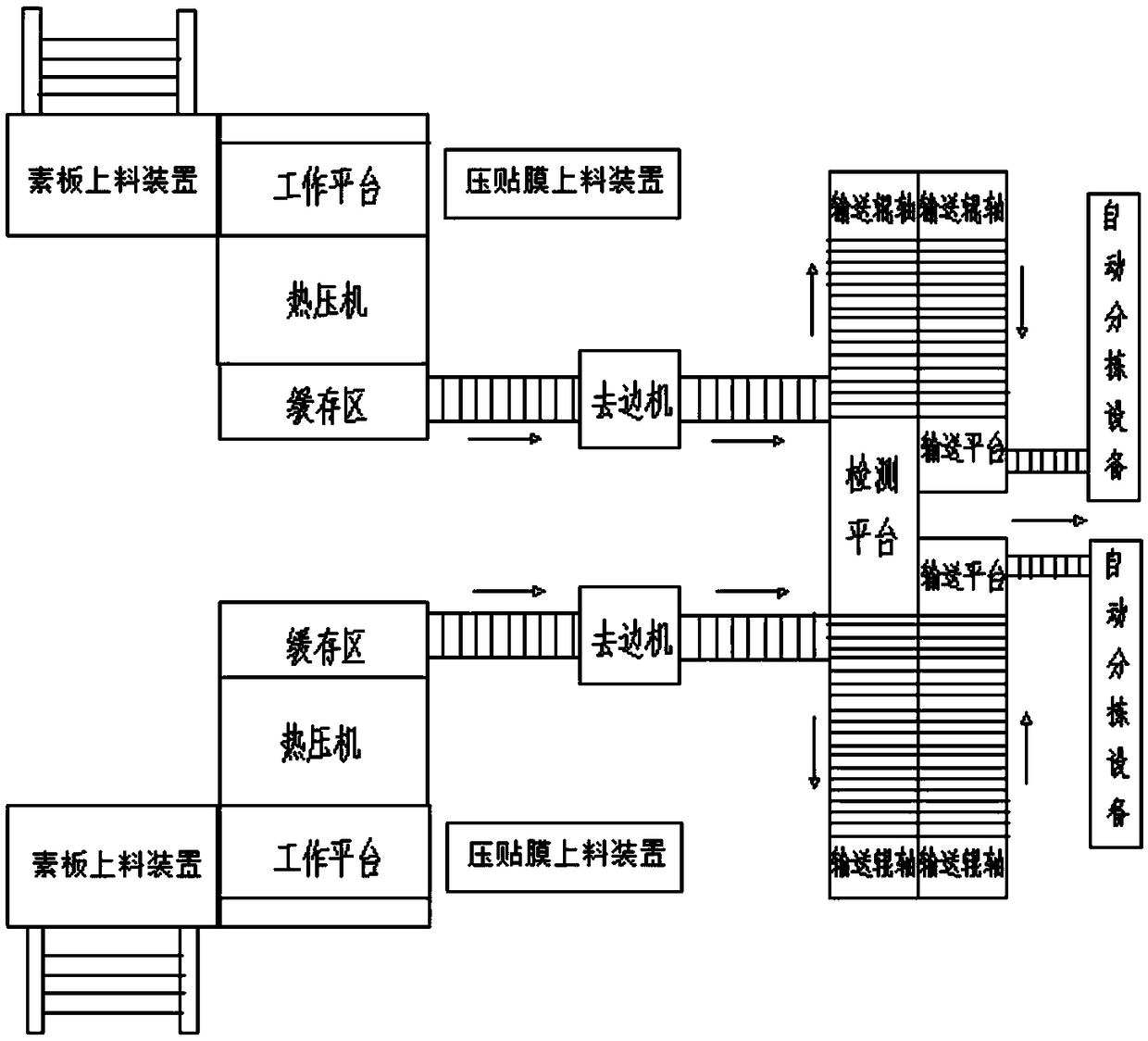

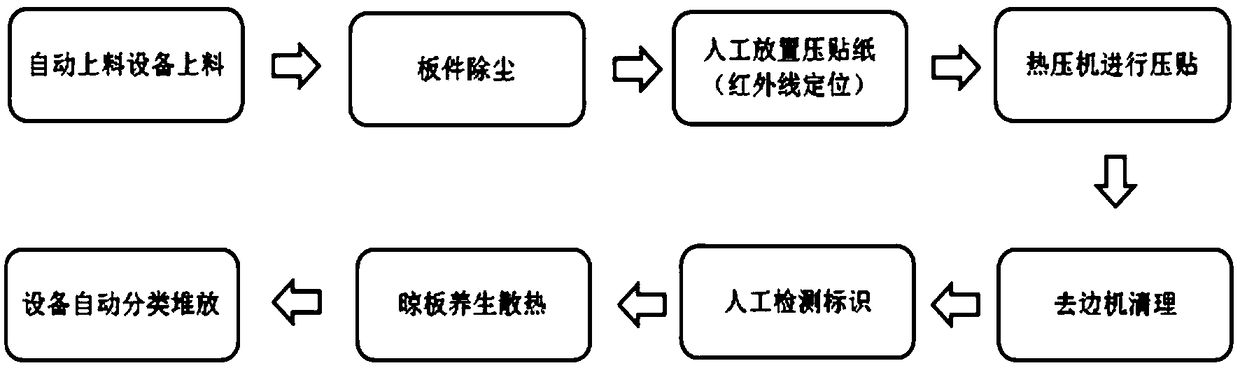

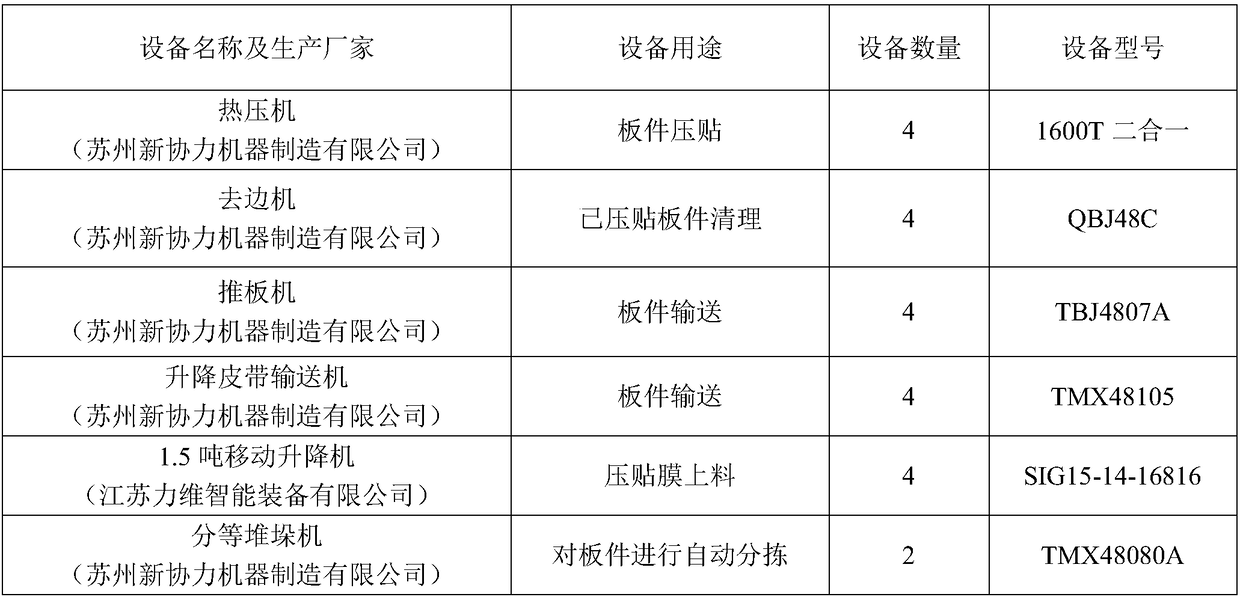

Plate press-fit two-in-one production process

InactiveCN108973296AQuality improvementReduce stress defectsLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses a plate press-fit two-in-one production process. The equipment adopted by the process comprises a plain panel feeding device, a hot press, a working platform, an edge removingmachine, a detection platform and an automatic classification device; the process comprises the following steps: firstly, manually paving the flip side of press-fit film reversely on the working platform to serve as lower-layer press-fit film; pressing a plain panel on the reversely paved press-fit film through the plain panel feeding device; then paving upper-layer press-fit film on the upper surface of the plain panel; sending the plain panel between hot pressing plates to carry out hot pressing through the conveying carriage of the hot press, and after the hot pressing is completed, sendingthe plain panel to a side removing machine for removing a side through a conveying device; enabling a side-removed press-fit plate to be manually detected on the detection platform, pasting a classification label according to a detection result, and then sending the press-fit plate to a press-fit plate classification device to be classified through a conveying roller; enabling the next plain panel, on which the press-fit film is paved, to be installed according to step 4 to step 6, operating repeatedly, repeating the cycle to perform continuous production. According to the furniture producedby the process disclosed by the invention, the product yield is high, the quality is stable, the cost is lowered, and the efficiency is improved.

Owner:索菲亚家居湖北有限公司

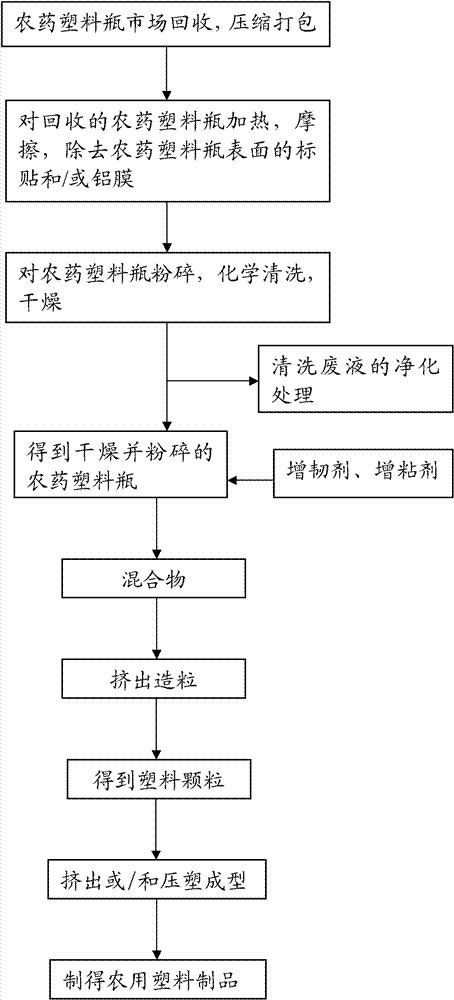

Pesticide plastic bottle recycling method, agricultural plastic product and rice seeding tray

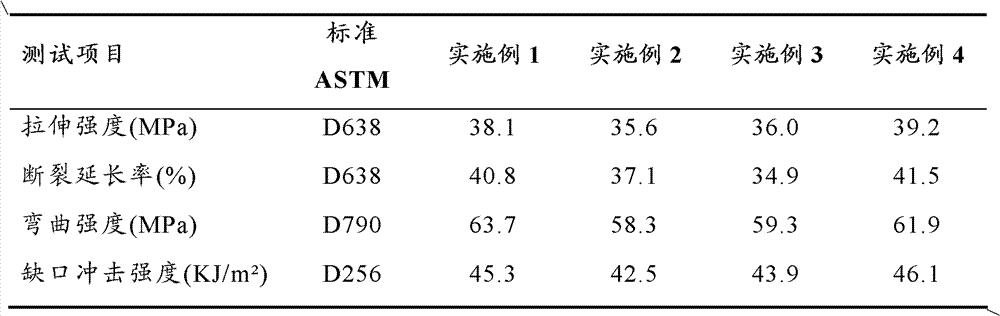

ActiveCN102528964BImprove toughnessImprove impact resistanceCultivating equipmentsEnvironmental resistancePesticide residue

The invention provides a pesticide plastic bottle recycling method, an agricultural plastic product and a rice seeding tray. The pesticide plastic bottle recycling method comprises the following steps of: heating a recycled pesticide plastic bottle, rubbing to remove a label and / or aluminium foil on the surface of the pesticide plastic bottle; smashing the pesticide plastic bottle with the label and / or aluminium foil removed, carrying out chemical cleaning, drying, adding flexibilizer and tackifier and mixing to obtain mixture; and extruding and pelleting the mixture to obtain plastic particles. The invention also relates to an agricultural plastic product prepared by utilizing the plastic particles prepared by the pesticide plastic bottle recycling method by virtue of extruding and / or compression moulding. The pesticide plastic bottle recycling method provided by the invention has simple process and is economic and environmentally friendly, and recycling of resource is realized. The agricultural plastic product prepared by the plastic particles prepared by adopting the method provided by the invention is safe and environmentally friendly, no pesticide residue is kept, and the agricultural plastic product has high shock resistance, is endurable and has low production cost.

Owner:SHENZHEN NOPOSION AGROCHEM

Static electricity elimination apparatus of paper cutting machine

InactiveCN105430856AImprove static elimination efficiencyNot easy to cause depositionElectrostatic chargesGraphite carbonPulp and paper industry

The invention discloses a static electricity elimination apparatus of a paper cutting machine. The apparatus comprises a paper holder, oil pump conveying rolls, a base, a rack, a static electricity elimination rod, a graphite carbon brush, a paper winding drum, a conveying apparatus, a metal conductive rod and a static electricity elimination bar, wherein the oil pump conveying rolls are symmetrically arranged at the lower end of the paper holder; the paper holder is mounted at the upper end of the base; the conveying apparatus is arranged on the paper holder and the rack; a paper deviation corrector is arranged on the rack; a main cutter is arranged at one end of the paper deviation corrector; the static electricity elimination rod is arranged at one end of the main cutter; the static electricity elimination bar is connected to the static electricity elimination rod; the graphite carbon brush is arranged at one end of the static electricity elimination rod; and the paper winding drum is arranged at one end of the graphite carbon brush. According to the static electricity elimination apparatus of the paper cutting machine, the static electricity elimination efficiency is high, the paper scrap deposition is difficultly caused, the short circuit is difficultly formed to damage a device, the production efficiency and the product quality are improved, the safe production is achieved, and the purchase expense of a professional static electricity elimination apparatus is removed.

Owner:TIANJIN LIANSEN PACKAGING PROD

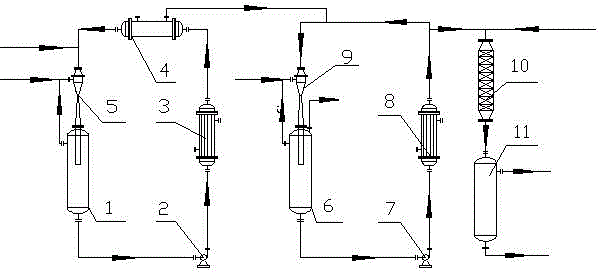

Anthraquinone hydrogen peroxide production device

InactiveCN103708426BCycle fastImprove mass transfer effectPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenation reactionTower

The invention discloses a device for producing hydrogen peroxide by adopting an anthraquinone process. The device comprises a hydrogenation reaction unit, an oxidation reaction unit and an extraction separation unit. A loop reactor with a simple structure is used for replacing the current hydrogenation and oxidation reaction equipment with huge volume, and a static mixer and an oil and water separator which are very small in volume are used for replacing an extraction tower with huge volume and low efficiency, thus the production process is simple, the volume of the equipment is very small, the investment scale of the device is saved, and the investment is saved by about 80 percent in comparison with that of a device for producing hydrogen peroxide with the same capacity.

Owner:石祖嘉

Injection molding material receiving detection packaging machine

PendingCN114802982AAvoid bulk exceptionsAvoid secondary scratchesPackaging automatic controlDisplay deviceProcess engineering

The invention relates to the technical field of machinery, and discloses an injection molding material receiving detection packaging machine which comprises a carrier, a feeding device is arranged on one side of the carrier, a feeding track is arranged at the position, corresponding to the feeding device, of the carrier, and carrying equipment and a CCD detection device are arranged at the position, corresponding to the feeding track, of the carrier. The carrier is fixedly provided with a CCD display device and a control interface device, the discharging end of the feeding rail is provided with a discharging device, and the discharging position of the discharging device is provided with a disc placing device. According to the injection molding material receiving detection packaging machine, the CCD detection device is arranged, so that defective products can be automatically recognized, batch abnormity is avoided, the production efficiency is improved, and the production cost is reduced. And manual inspection is not needed, so that the problems of relatively waste of labor and relatively waste of time caused by manual quality inspection of existing equipment are solved.

Owner:NINGBO ZSNOW ELECTRONICS

Equipment for processing tobacco leaves

A tobacco leaves processing apparatus for removing free nicotine, odor and stimulating substance from tobacco leaves iscomposed of a cylindrical body with drum, supporting frame and spray tube in it. Said drum is supported by the rollers on said supporting frame and is rotating on the rollers under the action of external driver. The liquid additive is sprayed onto the tobacco leaves via said spray tube.

Owner:于开平 +3

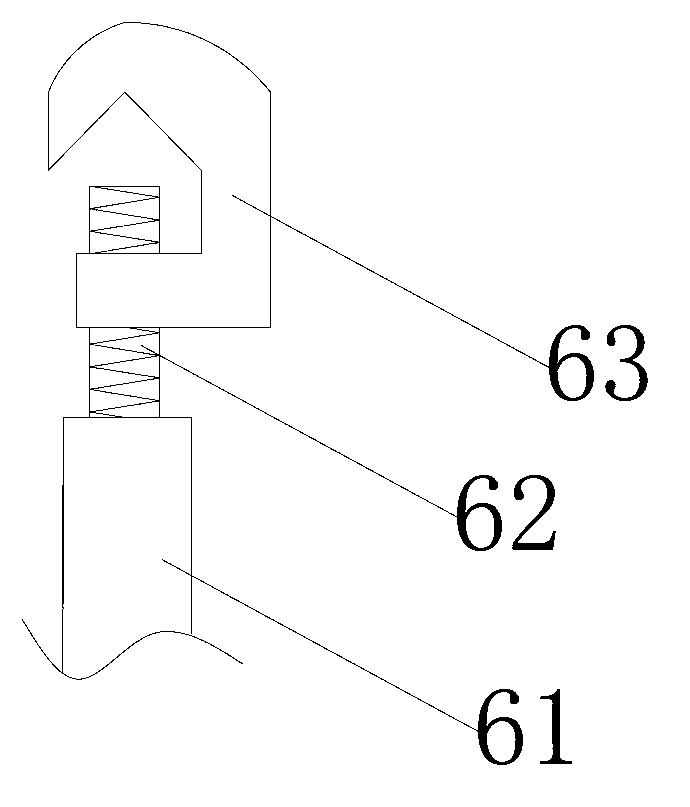

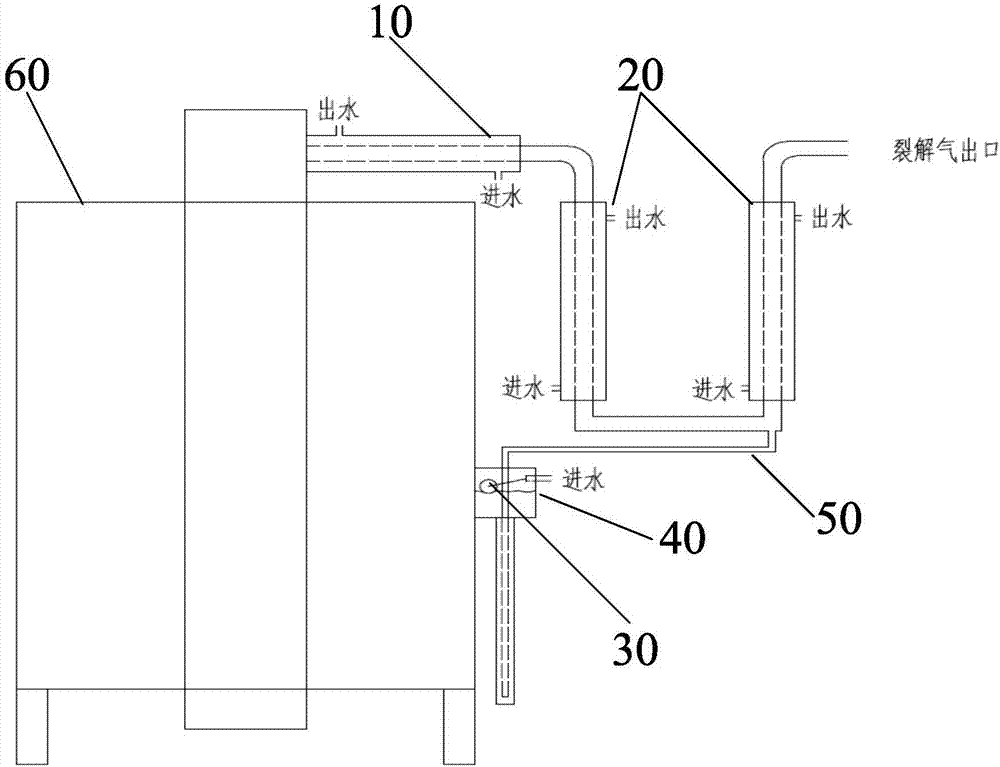

Efficient pyrolysis gas water vapor removal device

PendingCN107261776AAvoid damageReduce water vaporGaseous fuelsDispersed particle separationThermodynamicsWater vapor

The invention provides an efficient pyrolysis gas water vapor removal device. The efficient pyrolysis gas water vapor removal device is used for a heat absorption type gas generator for heat treatment on automobile parts and comprises a primary cooler, a secondary cooler, a water replenishing float ball, a water seal tank and a drain pipe. Connection relations include that the primary cooler is connected with the heat absorption gas generator and comprises a pipeline and a water jacket tank, and the pipeline is connected with the water jacket tank in a coated manner; the secondary cooler is connected with the primary cooler by a metal hose, the secondary cooler comprises another pipeline and another water jacket tank, and the other pipeline is connected with the other water jacket tank in a coated manner; the water replenishing float ball is mounted in the water seal tank, one end of the drain pipe is connected with the secondary cooler, and the other end of the drain pipe is connected with the water seal tank in an inserted manner. The efficient pyrolysis gas water vapor removal device has the advantages that water vapor in pyrolysis gas can be effectively reduced by the efficient pyrolysis gas water vapor removal device, the efficient pyrolysis gas water vapor removal device is reliable in structure, the quality can be guaranteed, and the market competitiveness of enterprises can be improved.

Owner:ZHEJIANG CHANGHUA AUTO PARTS +1

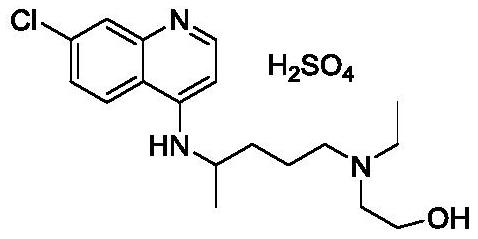

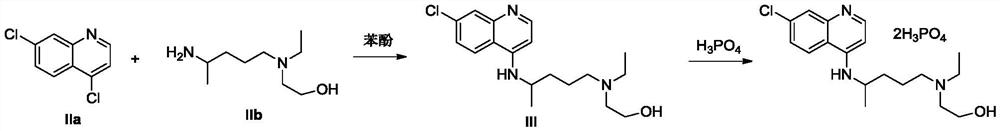

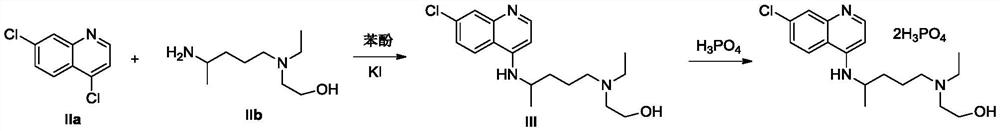

Preparation method of hydroxychloroquine

PendingCN112745263AHigh yieldHigh purityOrganic chemistryBulk chemical productionHydroxychloroquineQuinoline

The invention relates to a preparation method of hydroxychloroquine, which comprises the following steps: protecting hydroxyl of 5-(N-ethyl-N-ethoxyl)-2-aminopentane through a silanization reagent, removing amino protons from tetrahydrofuran or toluene by using a bis(trimethylsilyl lithium amide) solution to form amino anions, and carrying out a substitution reaction with 4.7 dichloroquinoline to generate hydroxychloroquine. The hydroxychloroquine and sulfuric acid are salified in an alcoholic solution to generate hydroxychloroquine sulfate, and the hydroxychloroquine sulfate preparation method provided by the invention has the characteristics of low toxicity, low pollution, high purity, low reaction temperature, short reaction time, high yield and the like, and is suitable for industrialization.

Owner:NANJING GRITPHARMA CO LTD

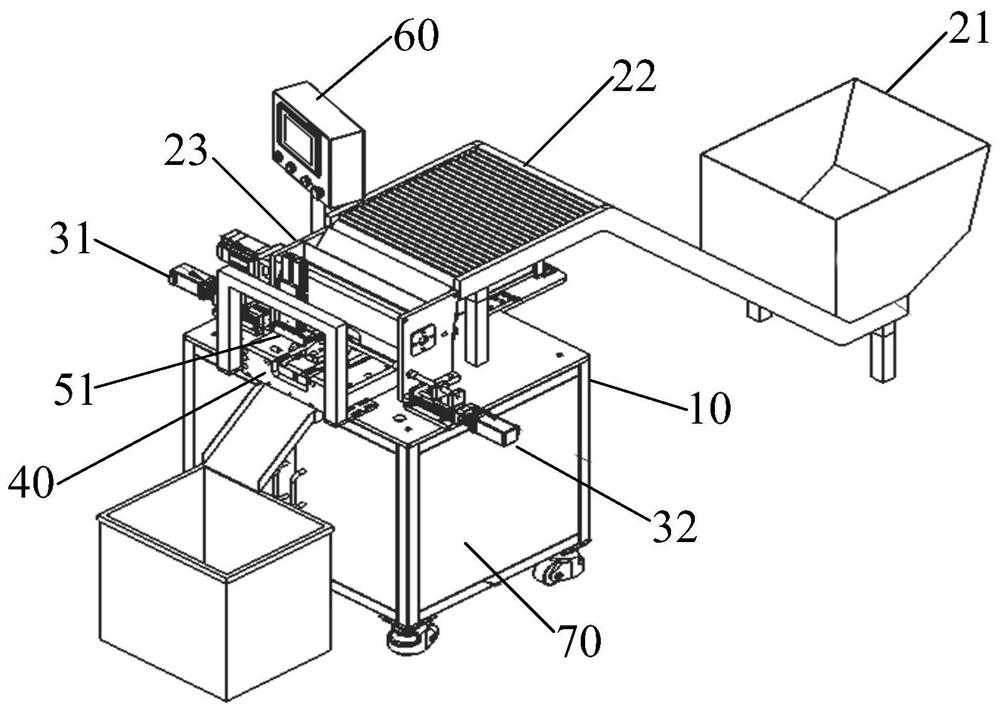

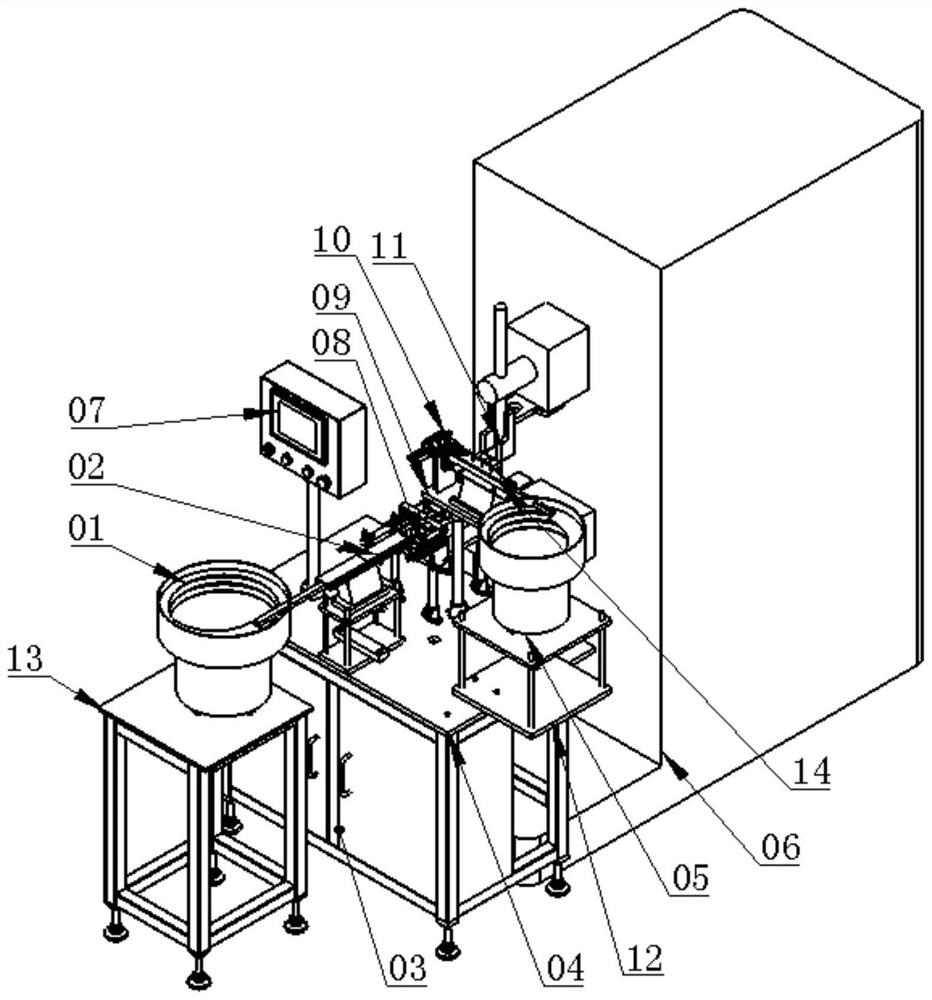

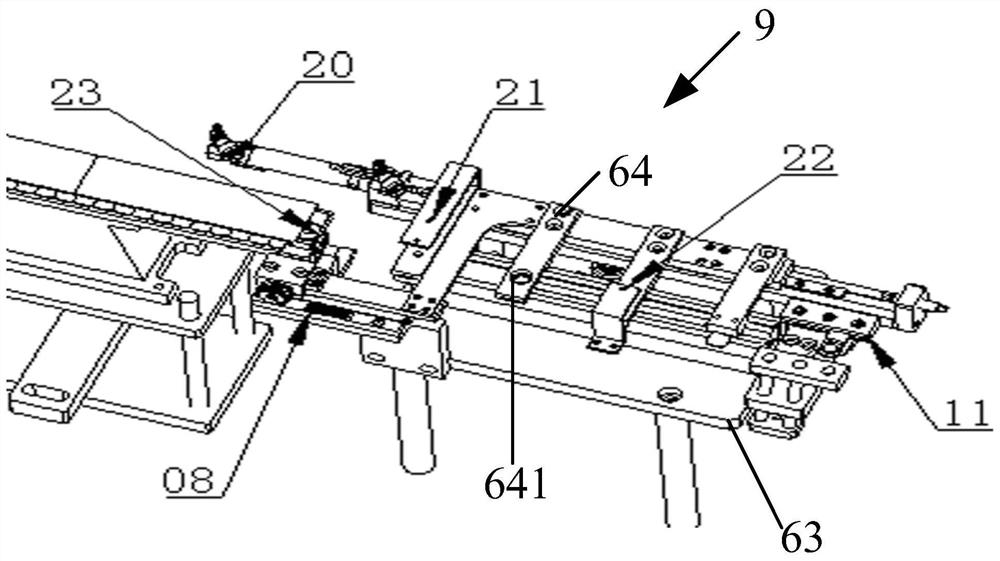

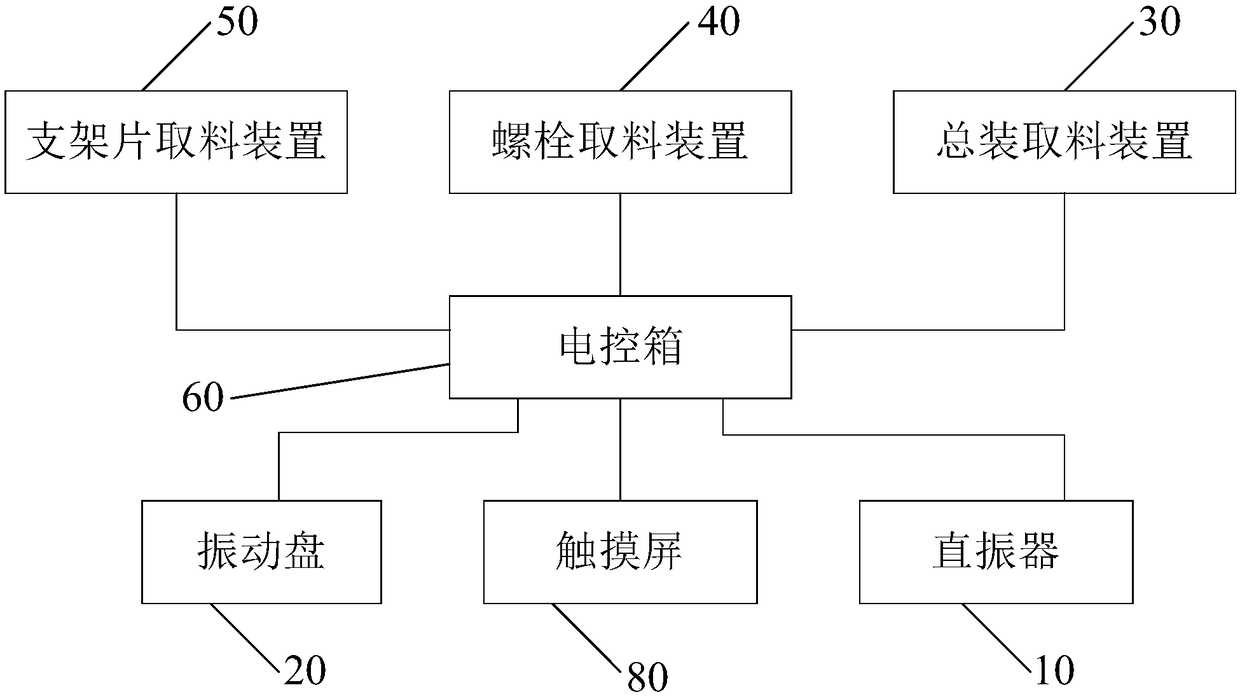

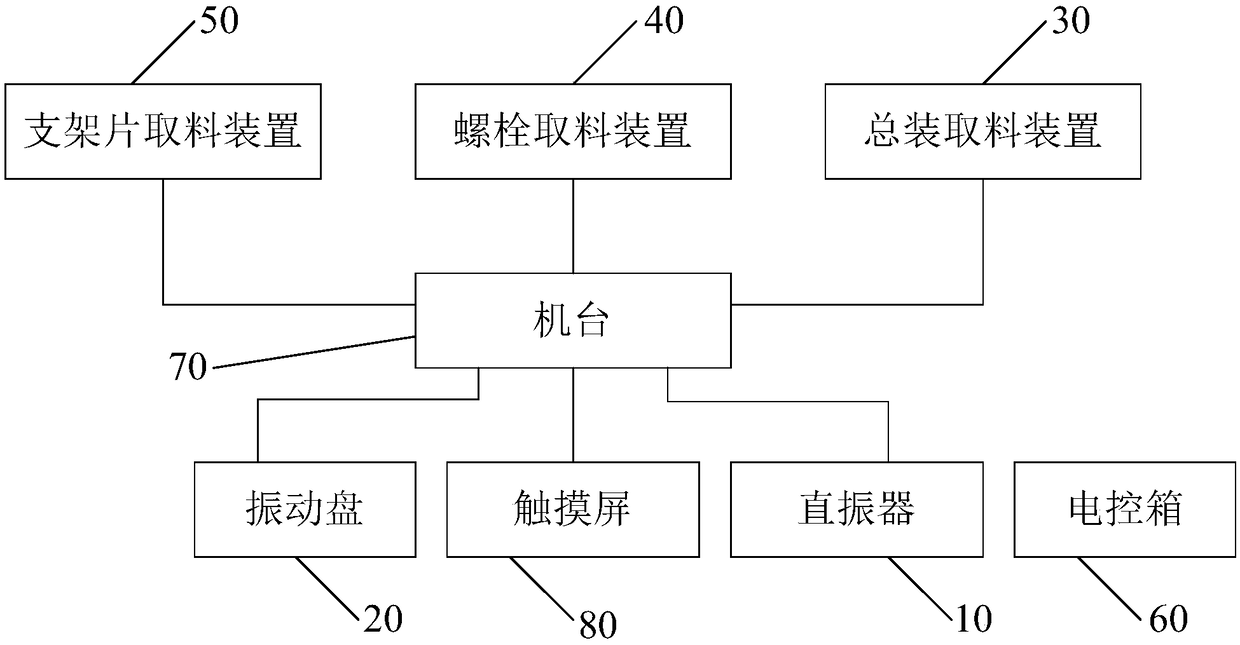

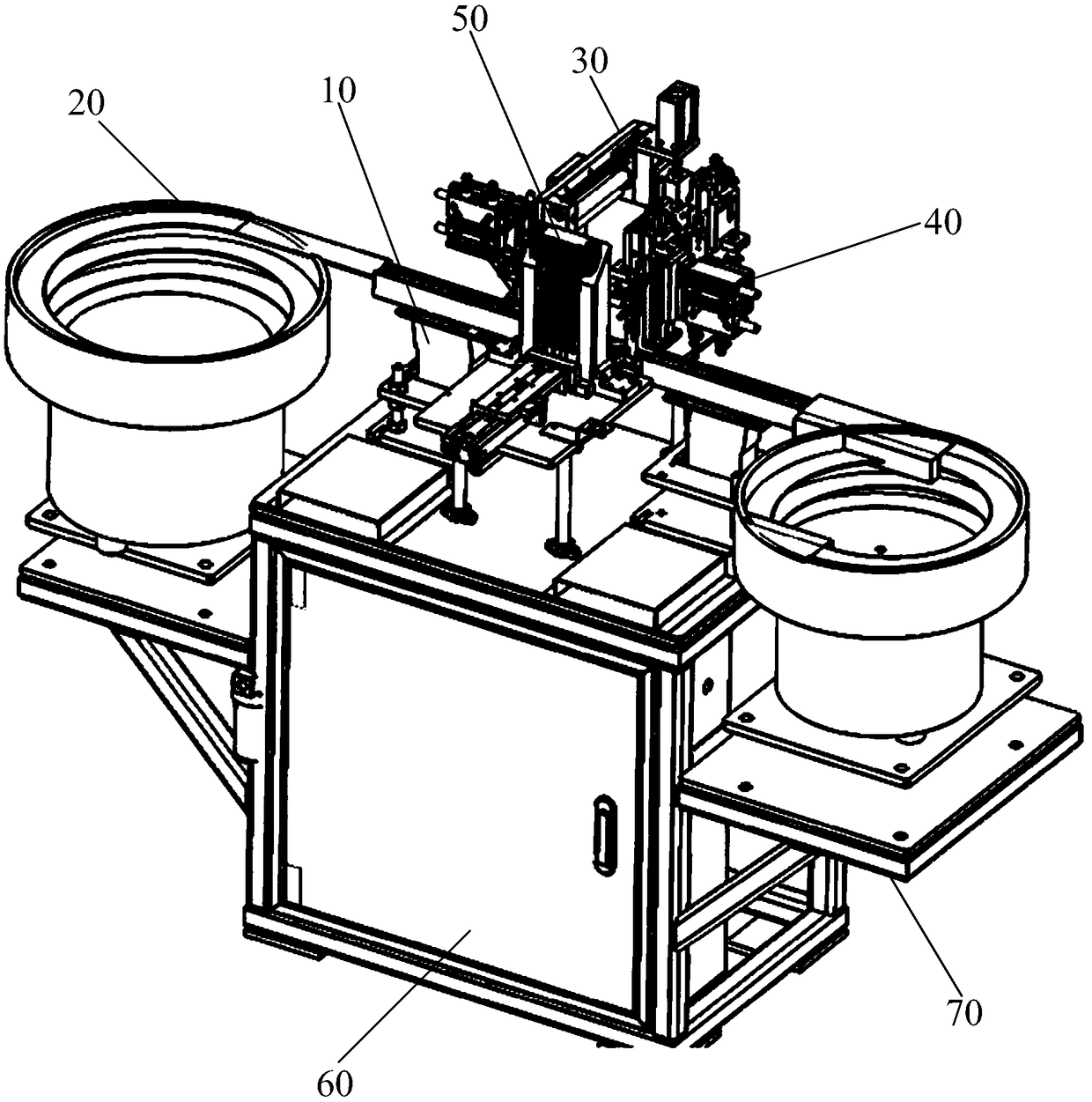

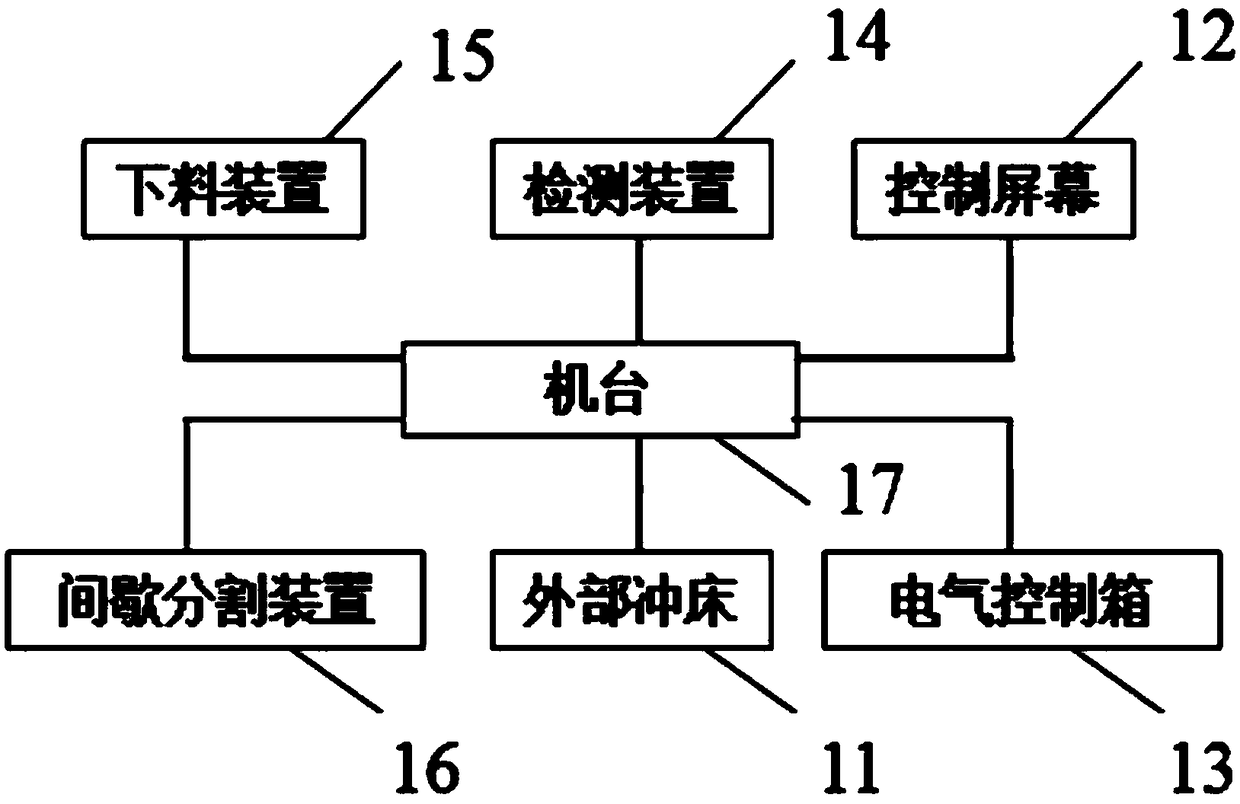

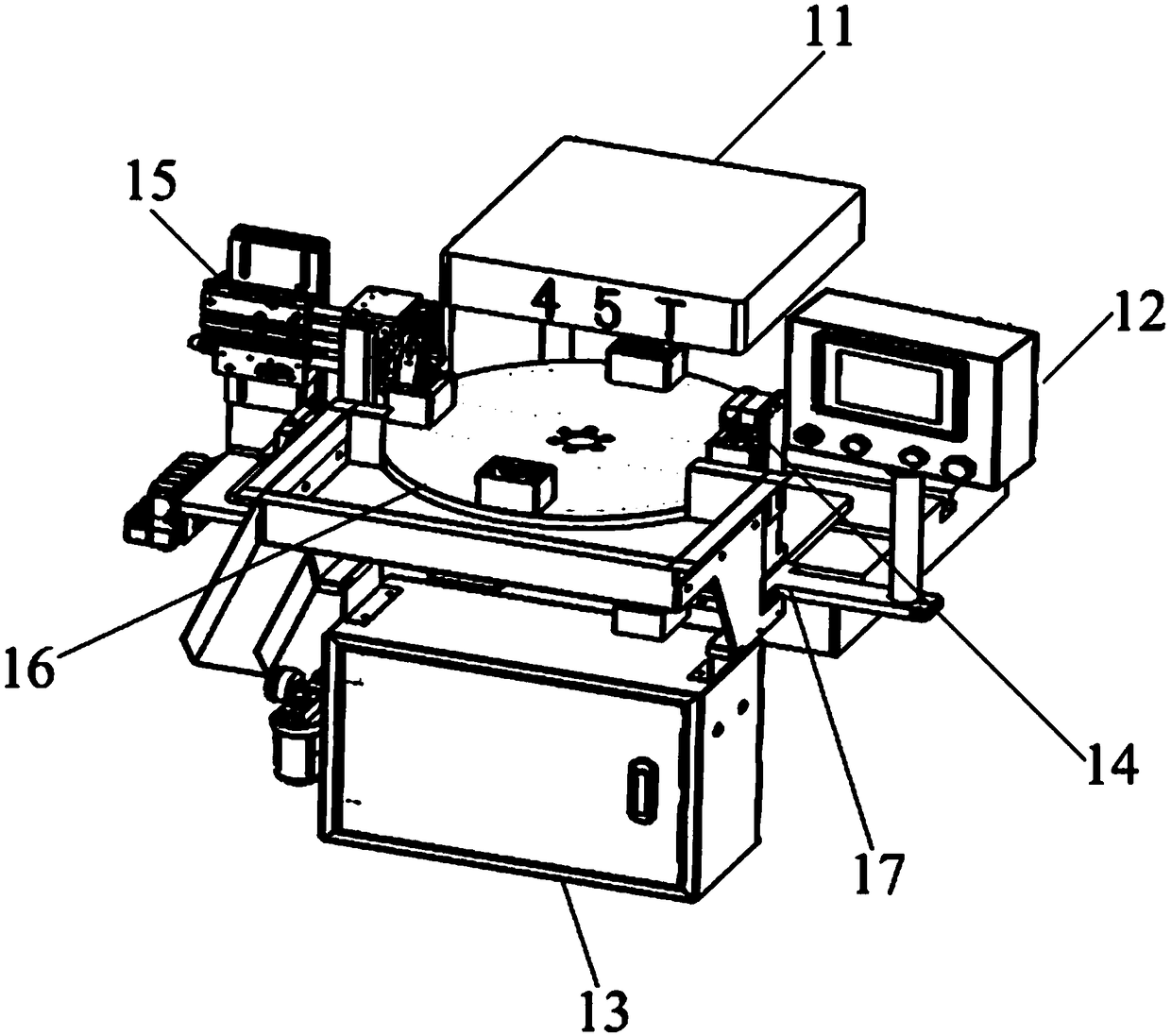

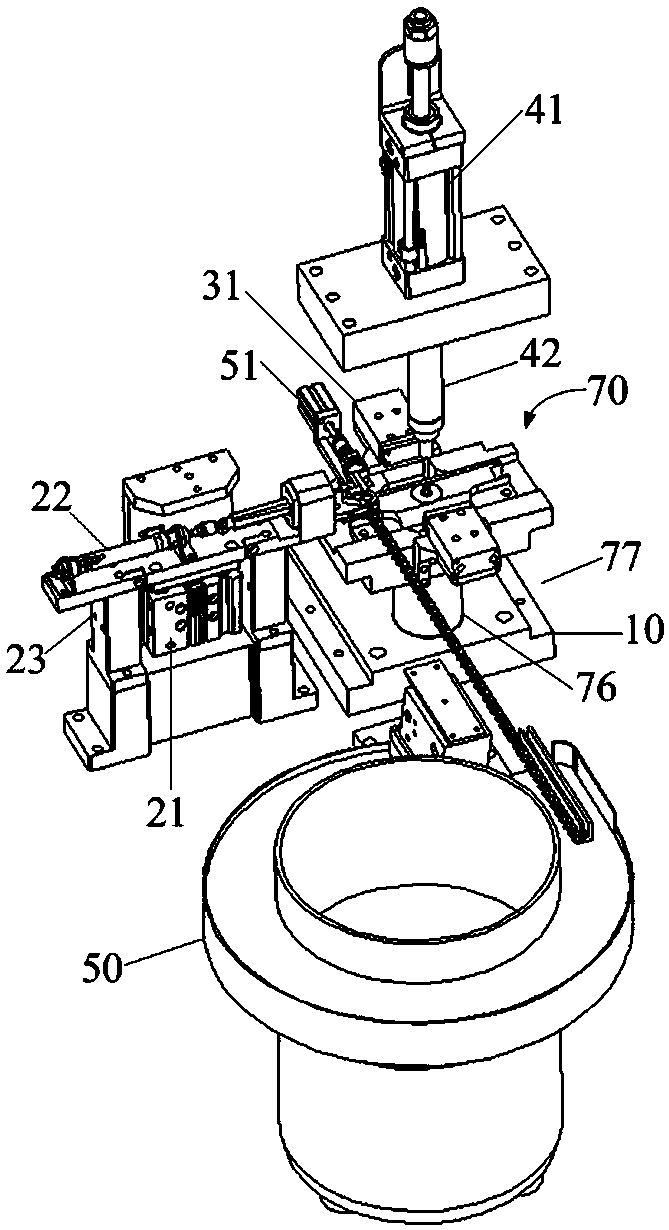

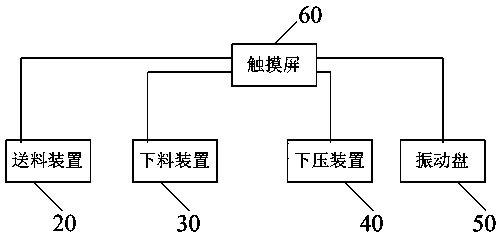

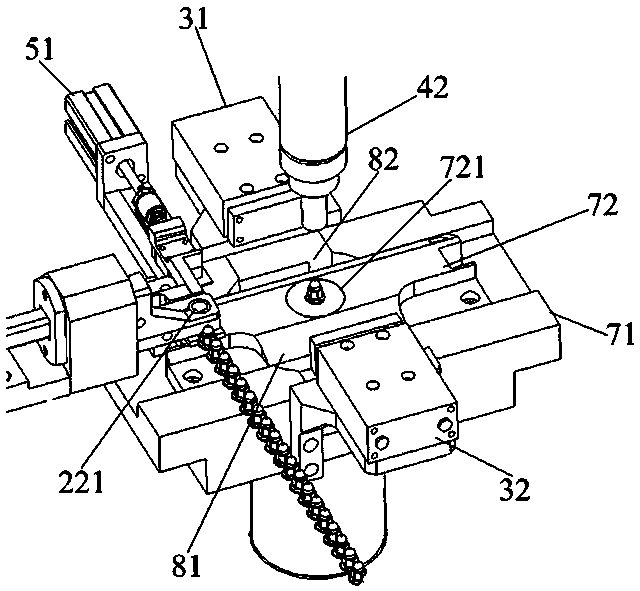

Automatic assembling and feeding device for high-precision bolt and bracket piece

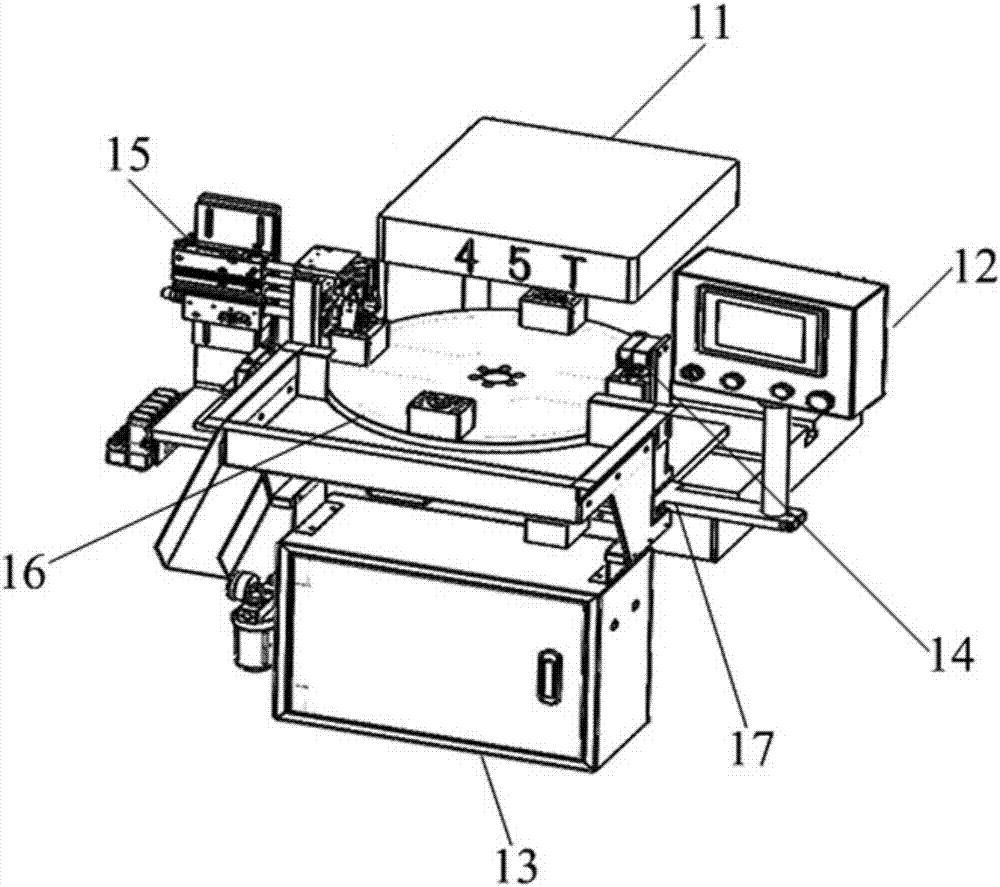

The invention provides an automatic assembling and feeding device for a high-precision bolt and a bracket piece, which comprises a machine platform, a support sheet material taking device, a bolt material taking device, a final assembly material taking device, a vibration disc, a vibration absorber, a touch screen and an electric cabinet; wherein the connection relation is that the support sheet material taking device, the bolt material taking device, the final assembly material taking device, the vibration disc, the vibration absorber, the touch screen and the electric control box are connected with the machine platform; the support sheet material taking device, the bolt material taking device, the final assembly material taking device, the vibration disc, the vibration absorber and the touch screen are respectively electrically connected with the electric control box; the support sheet material taking device comprises a first cylinder, a stack block, a feeding position sensor and a stack block placing table. The device is automatically taken and assembled, replaces manual production, has the advantages of reliable structure, high performance, convenient use, and easy maintenance,and meets safe production and improves market competitiveness of the enterprise.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

High-precision and high-efficiency automobile bolt and eccentric washer riveting device

Owner:ZHEJIANG CHANGHUA AUTO PARTS

A kind of separation method of titanium sponge titanium lump and separator

ActiveCN112481510BTake advantage ofReduce labor intensityLifting devicesProcess efficiency improvementEngineeringTitanium

Owner:ZUNYI TITANIUM

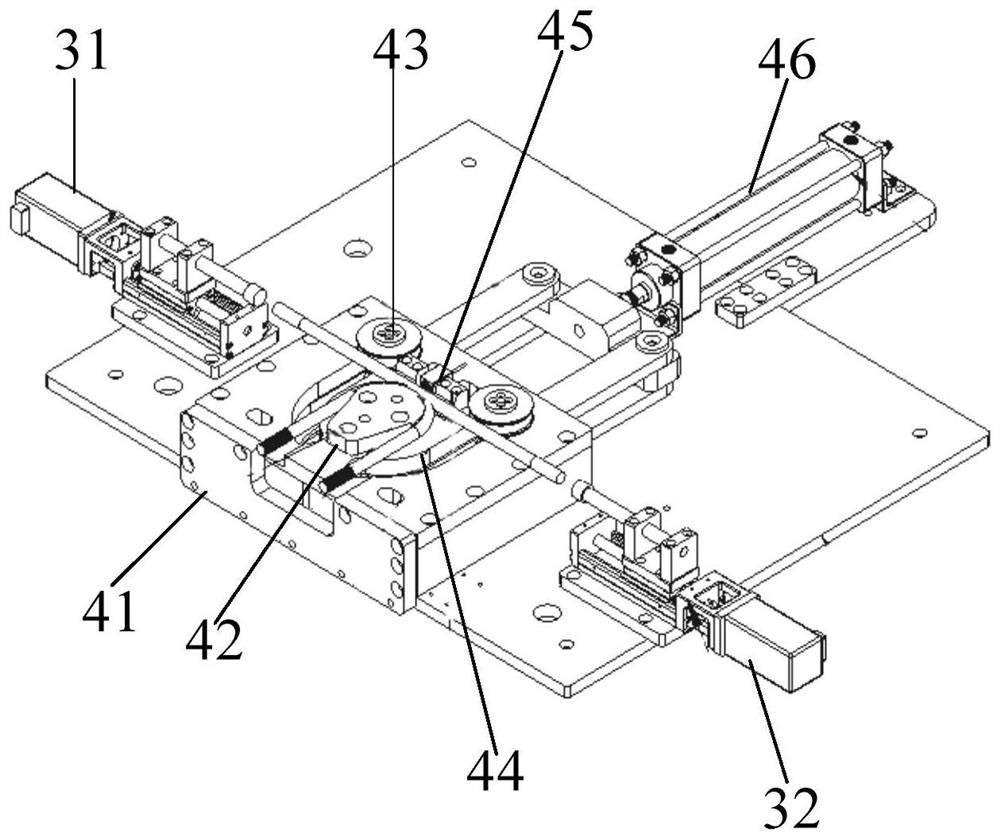

High-precision and high-efficiency riveting device for bolts and eccentric gaskets of automobiles

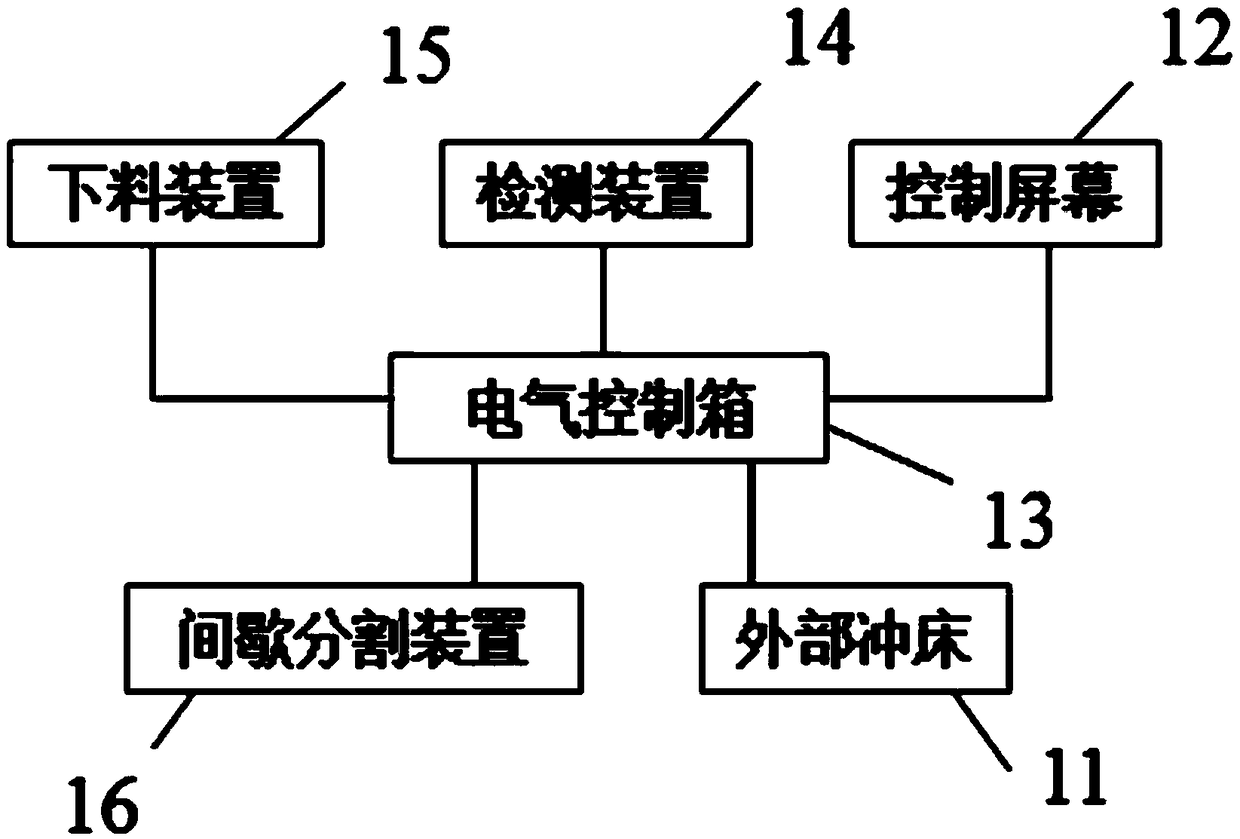

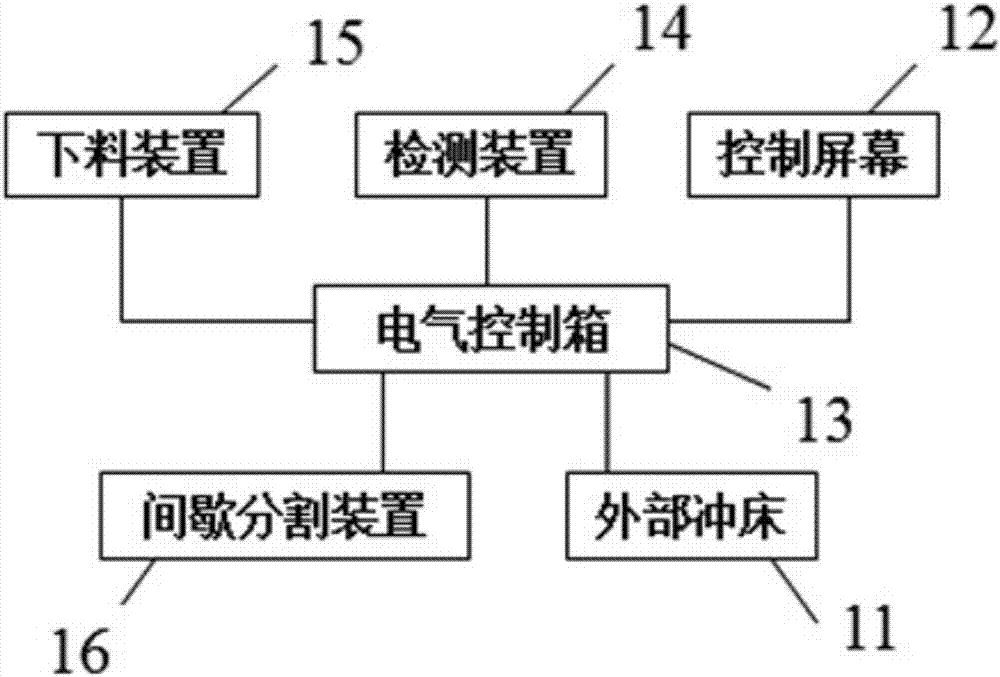

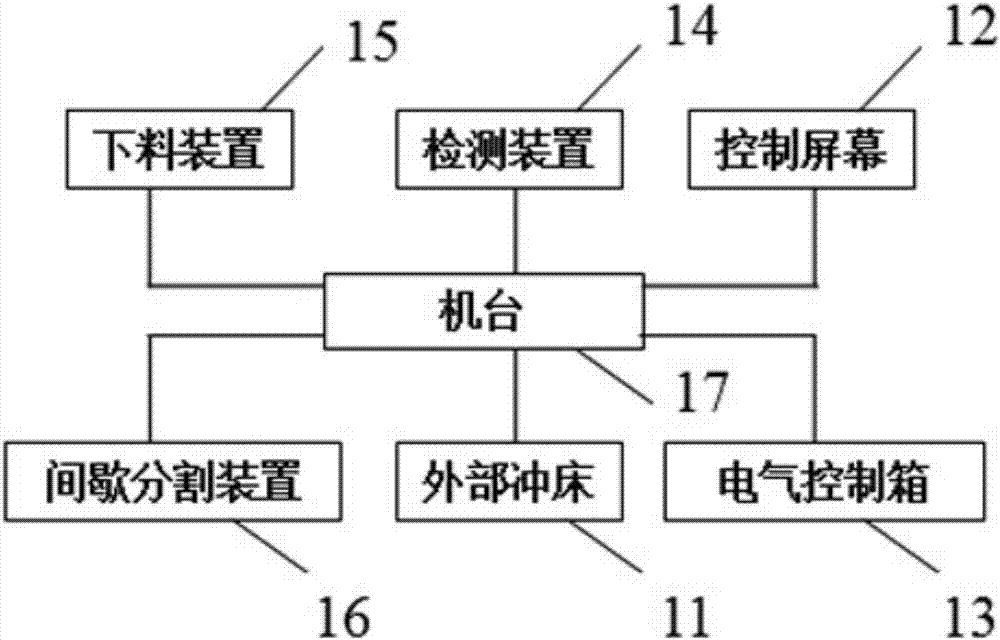

The invention provides a high-precision and high-efficiency riveting device for bolts and eccentric gaskets of automobiles. The riveting device comprises a machine table, a control screen, an electric control box, a detection device, a discharging device, an intermittent dividing device and an external punching machine, wherein the control screen, the detection device, the discharging device, the intermittent dividing device and the external punching machine are electrically connected to the electric control box; and the intermittent dividing device comprises a cam divider, an original point sensing assembly, an indexing rotary table, a stamping support and four quick-change lower stamping dies, wherein the cam divider is connected with the indexing rotary table, the indexing rotary table is connected with the quick-change lower stamping dies, the cam divider is connected with the machine table, the original point sensing assembly is connected with the machine table, the stamping support is connected with the machine table, the original point sensing assembly is electrically connected to the electric control box, and the cam divider is electrically connected to the electric control box. The riveting device is reliable in structure, high in performance, convenient to use, easy to maintain and capable of achieving safe production and improving market competitiveness of enterprises.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

Automatic induction, voice broadcast and video monitoring system for industrial dangerous area

PendingCN114051180AAvoid harmRealize monitoringTelemetry/telecontrol selection arrangementsClosed circuit television systemsVideo monitoringTelecommunications

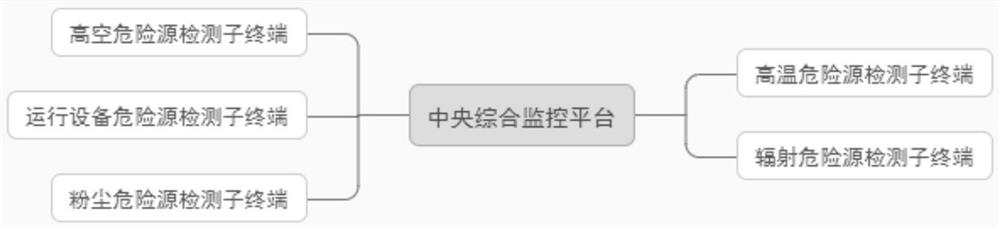

The invention discloses an automatic induction, voice broadcast and video monitoring system for an industrial dangerous area, and the system comprises a central comprehensive monitoring platform which is used for receiving sensor signals, geographical position information and area live videos of all sub-terminals which are in communication connection with the central comprehensive monitoring platform; the system comprises at least one sub-terminal, the sub-terminals are all in communication connection with the central comprehensive monitoring platform, are used for detecting danger signals and geographic positions of industrial dangerous areas and executing action instructions issued by the central comprehensive monitoring platform, and each sub-terminal comprises a sensor unit, a communication module, a position information module, an alarm device and a video monitoring unit. The sub-terminals can configure corresponding sensors according to different monitoring requirements and dangerous working conditions, monitoring of different industrial dangerous areas is achieved, the central comprehensive monitoring platform is in communication connection with the sub-terminals, and remote 'multi-point monitoring of one set of system and flexible coverage of multiple working conditions' is achieved.

Owner:武汉佰能盈天工程技术有限公司

Pumping unit brake locking device

InactiveCN102635655BReduce labor intensityTo achieve safe productionFluid removalBrake typesRocker armSpeed reduction

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

A stepped pouring system and pouring method for the front and back of multi-row formwork shells

ActiveCN111136250BEasy accessQuality improvementMould handling equipmentsMolten metal conveying equipmentsEngineeringLadle

The invention discloses a stepped pouring system and a pouring method for the front and back of multi-row mold shells. The multi-row formwork front and back stepped pouring system includes: a trolley with a front and a back; at least two rows of formwork, and the formwork is at a middle height between the front and the back of the trolley The two sides are low in a stepped arrangement, and a sprue cup is opened on the top of the mold shell; a ladle is located above the mold shell, and the ladle contains molten metal, wherein the sprue cup forms a connecting line. The slope of the ladle should be greater than or equal to the slope of the shape of the ladle; the molten metal in the ladle is poured on the front and / or the back of the trolley respectively and enters the ladle through the sprue cup inside the mold shell. The stepped pouring system on the front and back of the multi-row mold shells provided by the invention has the advantages of simple pouring work, high pouring quality of castings and ideal production efficiency.

Owner:HEFEI UNIV OF TECH

Welding strength automatic testing and sorting device

The invention provides a welding strength automatic testing and sorting device. The device comprises a stand, a feeding device, an unloading device, a pressing device, a vibration disc, a touch screen and an ejecting device, wherein the connecting relations are as follows: the feeding device, the unloading device, the pressing device, the vibration disc, the touch screen and the ejecting device are assembled and connected with the stand; the feeding device, the unloading device, the pressing device and the vibration disc are electrically connected with the touch screen; the ejecting device includes a support table, a support plate, a support column, a support spring, a thimble and a support cylinder; a support through hole is formed in middle of the support plate; one end of the support column is connected with the stand, and the other end is connected with the thimble; a pin hole is formed in the bottom of the support cylinder, and is corresponding to the thimble; and the bottom of the support cylinder is connected with the support through hole of the support plate. The device realizes automatic sorting and counting, accelerates the speed, replaces manual production, guarantees high quality and performances, achieves safe production, and improves the market competitiveness of enterprises.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com