Plate press-fit two-in-one production process

A production process, a two-in-one technology, applied in the sheet metal pressing production process, the plate pressing two-in-one production process field, can solve the problems of high labor intensity, poor bonding between stickers and plain boards, and stress delamination. Achieve the effect of saving labor cost, improving pressing quality and high product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is illustrated

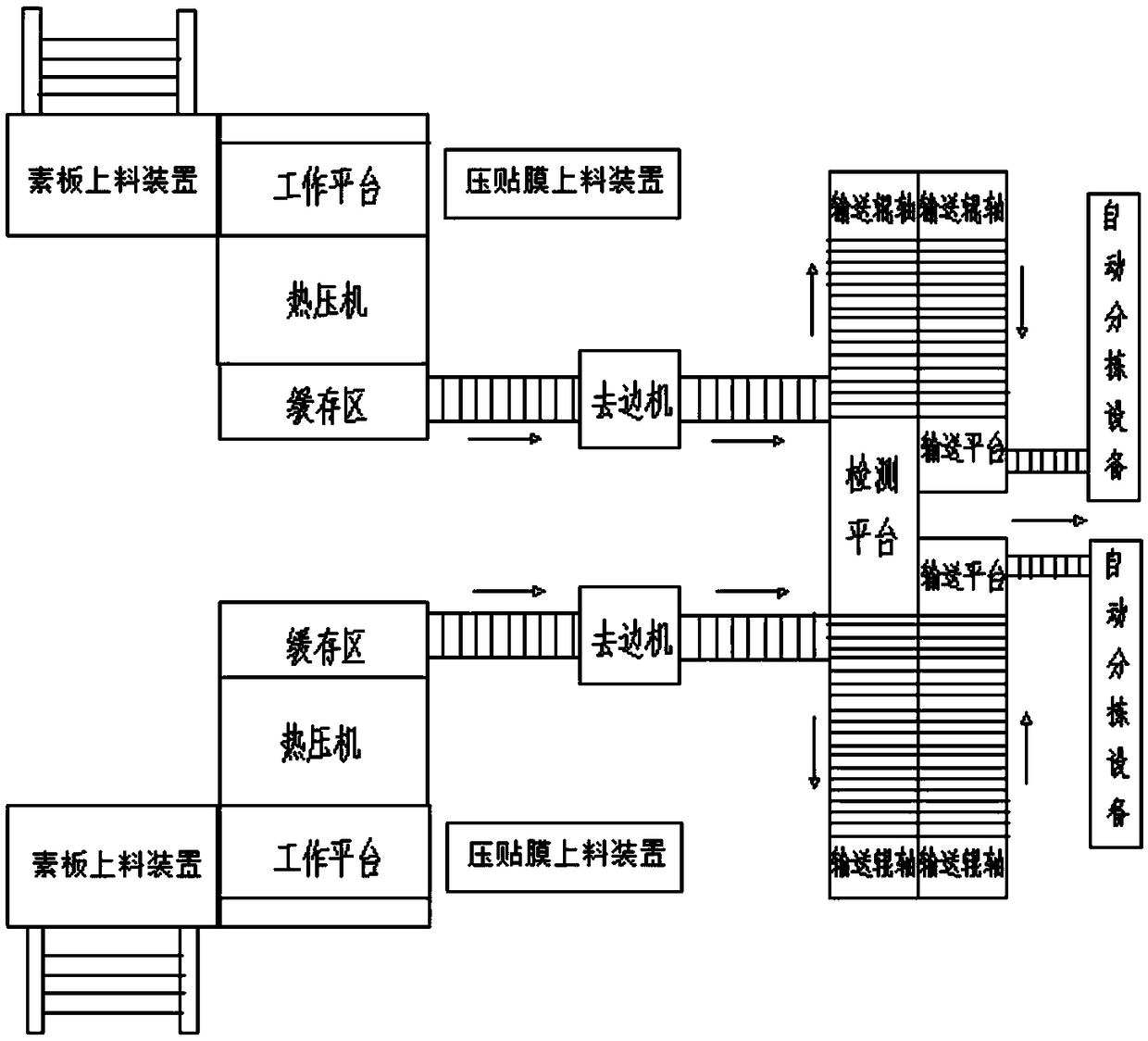

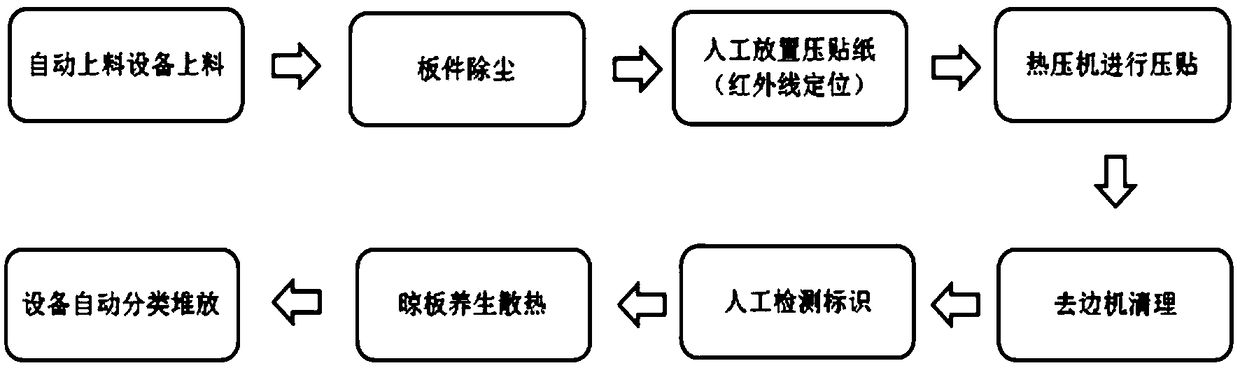

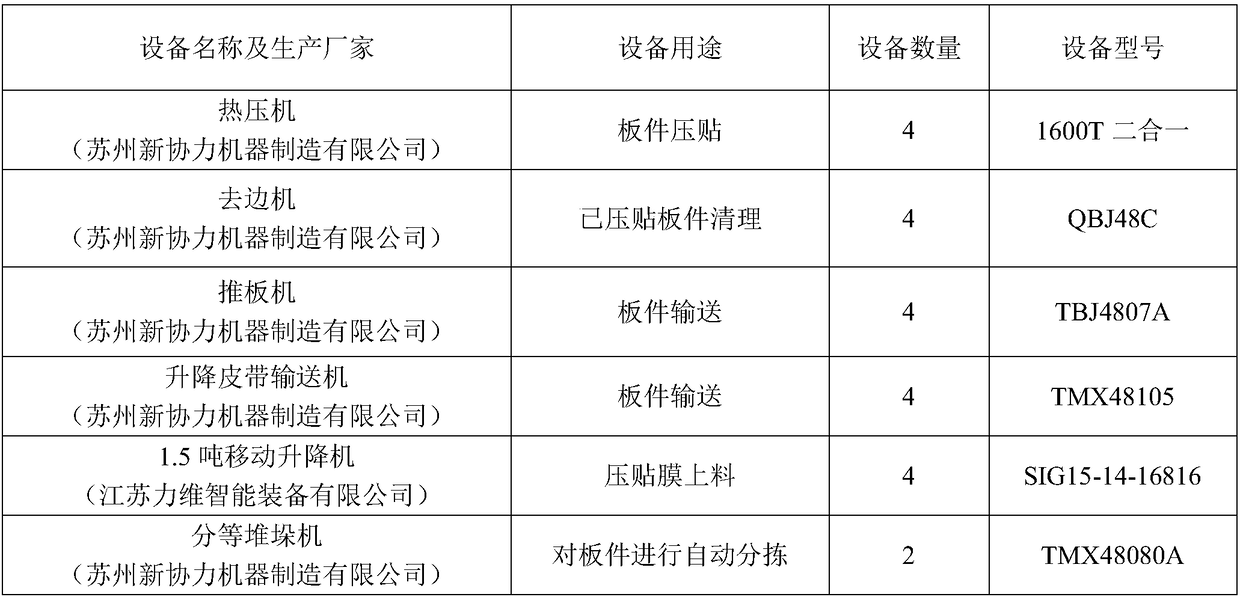

[0031] Such as figure 1 As shown, a two-in-one production process of plate pressing and lamination, the equipment used in this process includes a raw plate feeding device, a hot press, a working platform, a trimming machine, a detection platform and an automatic sorting device, and the layout of each device Such as figure 1 shown; the process includes the following steps:

[0032] Step 1. Firstly, manually turn the laminated film over and lay it on the working platform as the lower laminated film, and position it through the positioning device on the working platform;

[0033] Step 2. Load the raw board through the raw board feeding device, and press the plain board on the back-laid pressing film;

[0034] Step 3, and then manually lay a laminated film on the surface of the plain board;

[0035] Step 4. Send the sports car through the hot press to the hot pressing plate for hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com