Aluminum armour tape winding method

A winding method and aluminum-clad tape technology, applied in the field of aluminum-clad tape winding, can solve problems such as difficulty in ensuring safe distance, threats, and inability to guarantee, and achieve the effects of improving power supply reliability, applicability, and live working convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

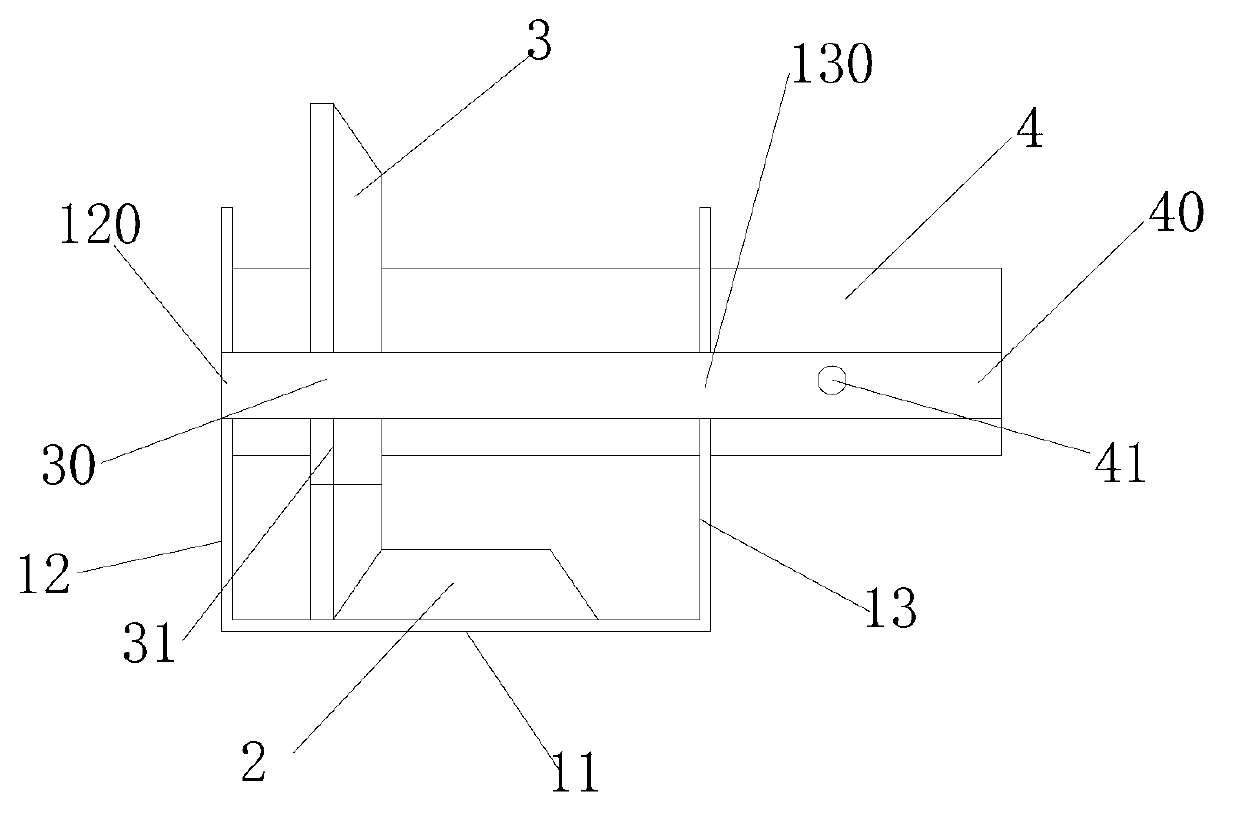

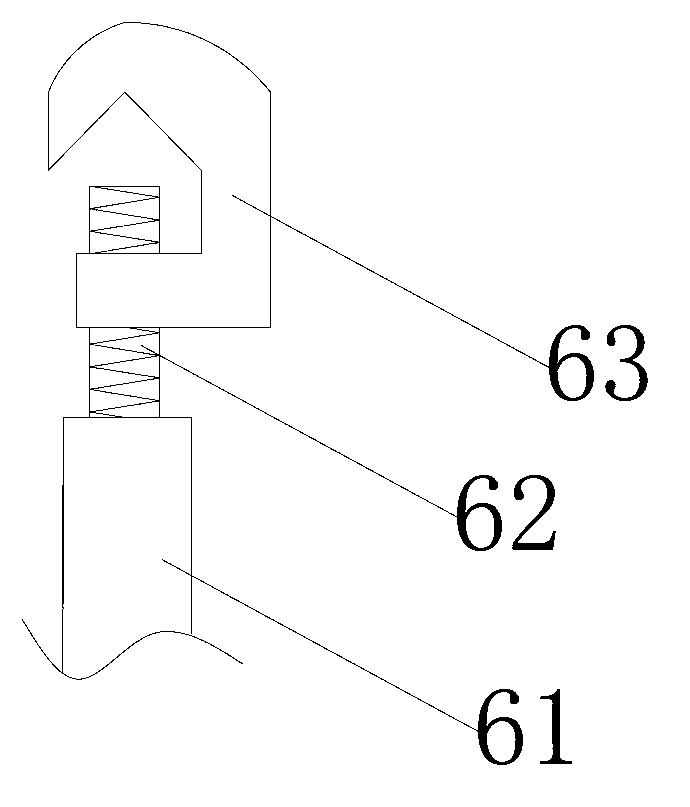

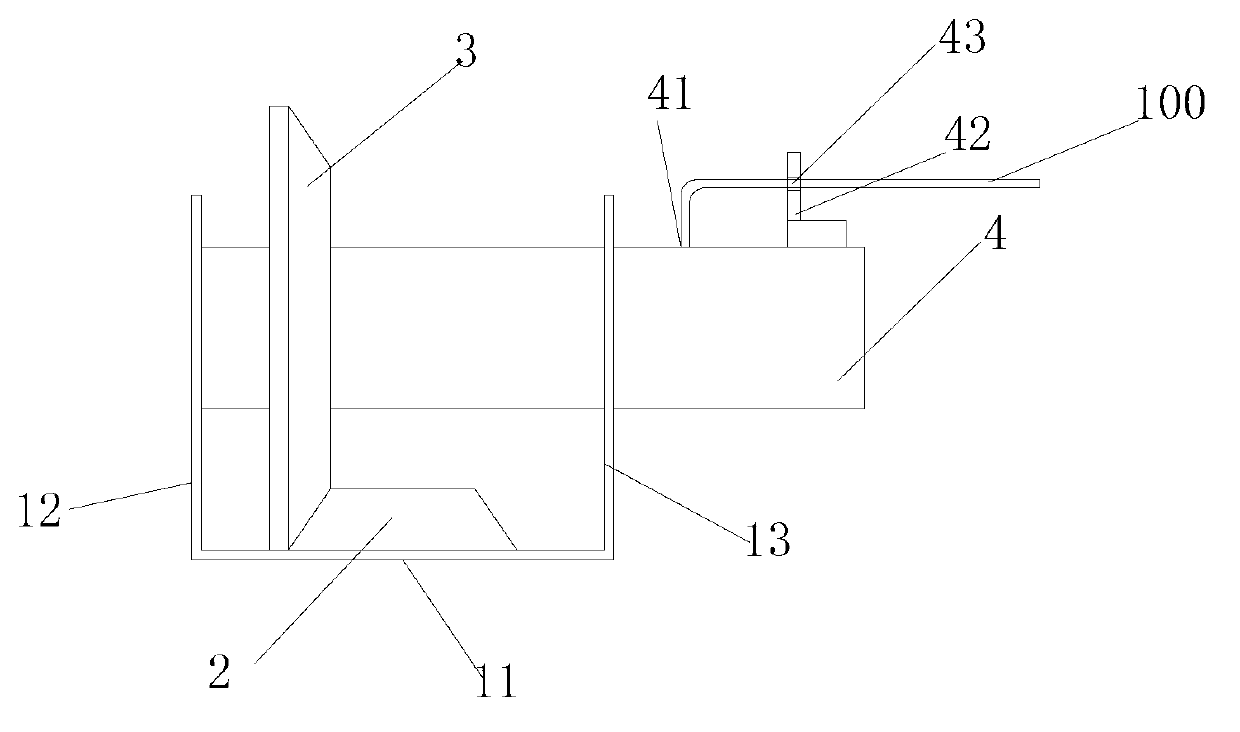

[0021] see Figure 1 to Figure 5 As shown, in the aluminum tape winding method of the present invention, the aluminum tape winding operation lever and the auxiliary clamping lever 6 are used to perform aluminum tape winding on the cable 200 .

[0022] The aluminum-clad tape-wound operating rod includes an insulating cylinder 1, a first gear 2, a second gear 3, a hollow shaft 4 and an insulating crank 5.

[0023] see figure 1 As shown, the insulating cylinder 1 is hollow, and a U-shaped supporting part is fixed on its top. The U-shaped supporting part includes a base 11 and a first supporting plate 12 and a second supporting plate 13 arranged in parallel on both sides of the base 11 . The length of the insulating cylinder 1 is greater than or equal to 1850mm. The hollow shaft 4 is installed on the first support plate 12 and the second support plate 13, and can rotate around the first support plate 12 and the second support plate 13; the outer periphery of the hollow shaft 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com