Pesticide plastic bottle recycling method, agricultural plastic product and rice seeding tray

A technology for plastic bottles and pesticides, applied in the field of engineering plastics, can solve the problems of no set of recycling and reuse methods, high processing costs, no enterprise recycling and utilization, etc., to achieve resource reuse, strong impact resistance, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

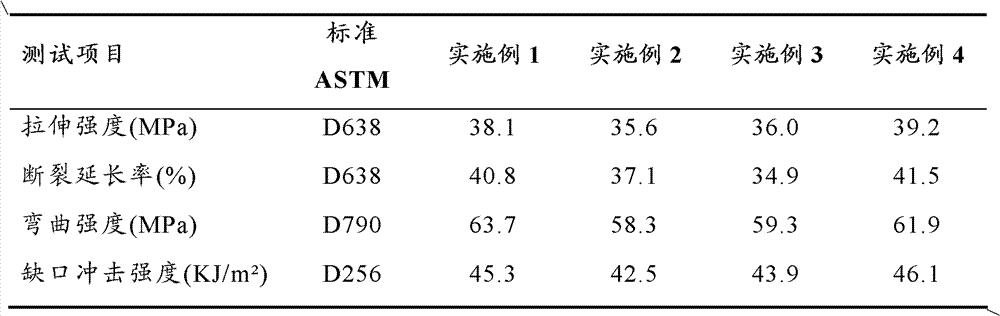

Examples

Embodiment 1

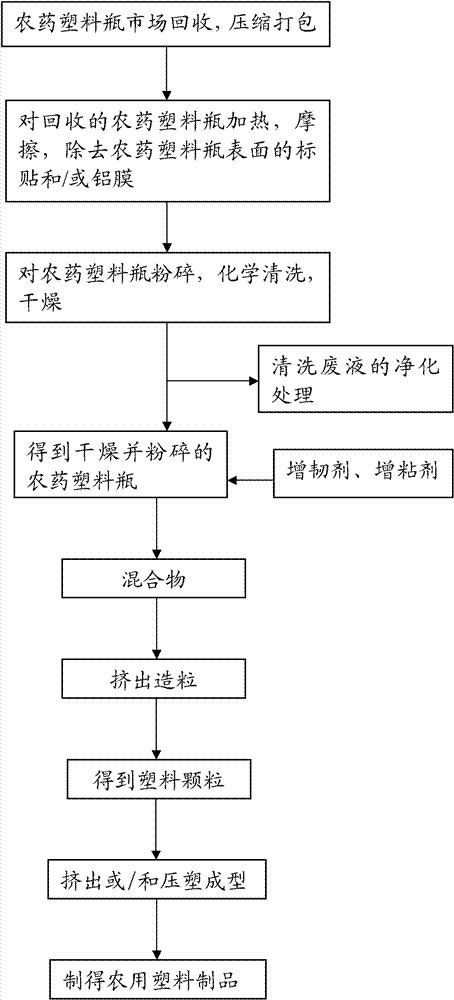

[0037] The method for recycling the pesticide plastic bottle comprises the following steps:

[0038]S11: Put the recycled pesticide plastic bottles into the toothed screw conveyor for transportation, heat up to 250°C during the conveying process, and use the helical teeth in the toothed screw conveyor to act on the pesticide plastic bottles to generate friction and remove The label and / or the aluminum film on the surface of the pesticide plastic bottle;

[0039] S12: Use the online high-speed pulverizer to crush the pesticide plastic bottles without labels and / or aluminum film, and then send them to the high-temperature cleaning tower for chemical cleaning at 70°C for 0.5h, then dry at 90°C for 2.5h, and then Adding the KT-16 toughening agent produced by Shenyang Ketong and 3% of the German BASF ADR-4370 tackifier to form a mixture by adding 1% by weight; wherein, the chemical cleaning agent used for this chemical cleaning contains 100% by weight The content is 2% NaOH (sodiu...

Embodiment 2

[0042] The method for recycling the pesticide plastic bottle comprises the following steps:

[0043] S21: Put the recycled pesticide plastic bottles into the toothed screw conveyor for transportation, heat up to 220°C during the conveying process, and use the helical teeth in the toothed screw conveyor to act on the pesticide plastic bottles to generate friction and remove The label and / or the aluminum film on the surface of the pesticide plastic bottle;

[0044] S22: Grind the pesticide plastic bottles without labels and / or aluminum film with an online high-speed grinder, and then send them to a high-temperature cleaning tower for chemical cleaning at 80°C for 0.7h, then dry at 100°C for 2h, and then add The KT-22 toughening agent produced by 1% Shenyang Ketong and 1% German BASF ADR-4370 tackifier are mixed to form a mixture by weight percentage; wherein, the chemical cleaning agent used in this chemical cleaning contains weight percentage Content is 3% NaOH (sodium hydroxi...

Embodiment 3

[0047] The method for recycling the pesticide plastic bottle comprises the following steps:

[0048] S31: Put the recovered plastic bottles of pesticides into the toothed screw conveyor for transportation, heat up to 285°C during the transportation process, and use the spiral teeth in the toothed screw conveyor to act on the plastic bottles of pesticides to generate friction and remove The label and / or the aluminum film on the surface of the pesticide plastic bottle;

[0049] S32: Grind the pesticide plastic bottles with labels and / or aluminum film removed using an online high-speed pulverizer, and then send them to a high-temperature cleaning tower for chemical cleaning at 60°C for 1 hour, then dry them at 80°C for 3 hours, and then add weight The KT-22A toughening agent produced by 3% Shenyang Ketong and 5% of the German BASF ADR-4370 tackifier are mixed to form a mixture; wherein, the chemical cleaning agent used for this chemical cleaning contains the weight percentage 1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com