Online repair system and repair method after sealing failure of pipeline assembly

A technology for sealing failure and repairing systems, applied in the direction of pipeline systems, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as increasing the hidden danger of fire and explosion, inducing cancer, toxic and harmful materials, etc., to eliminate odor and The effect of disease inducement, improving health index, and improving production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

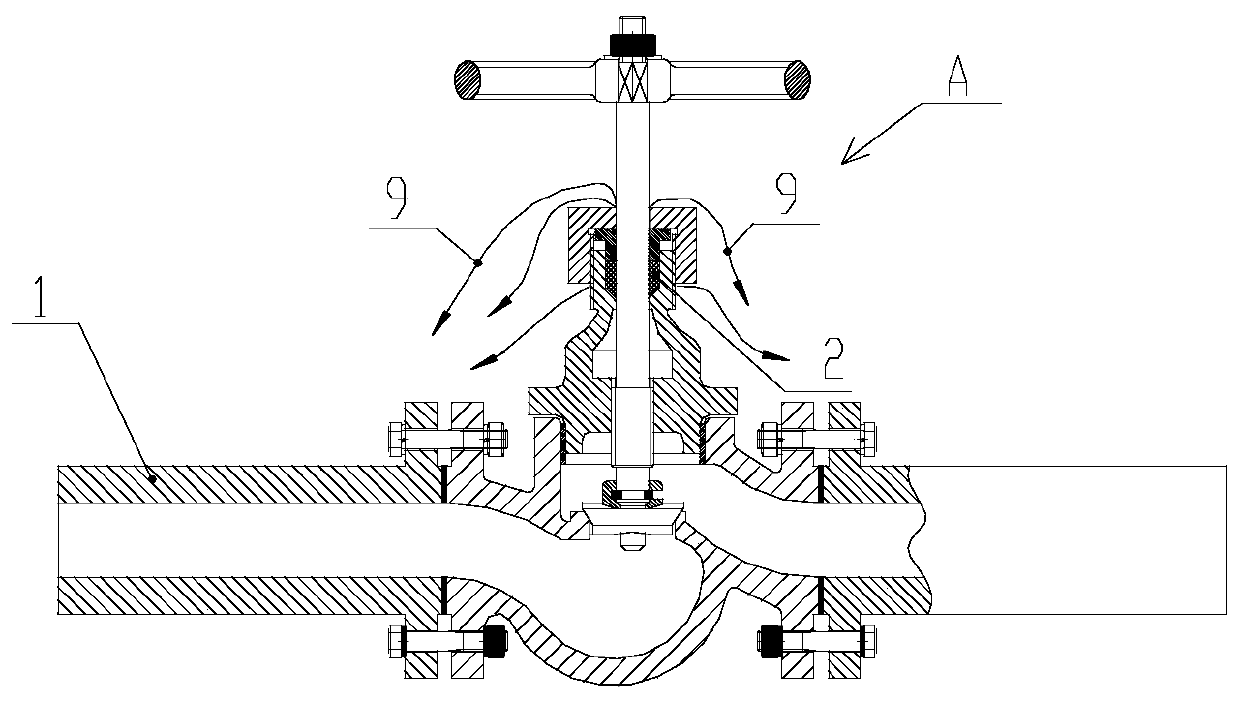

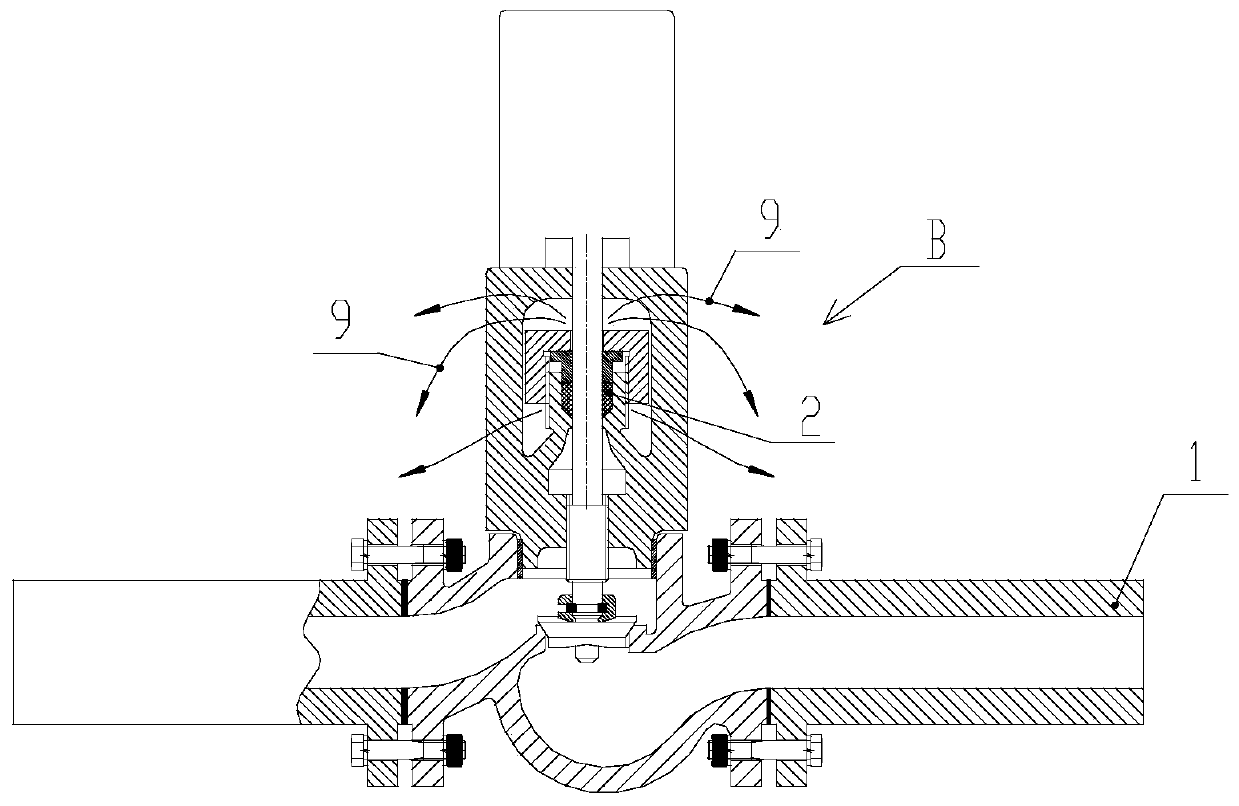

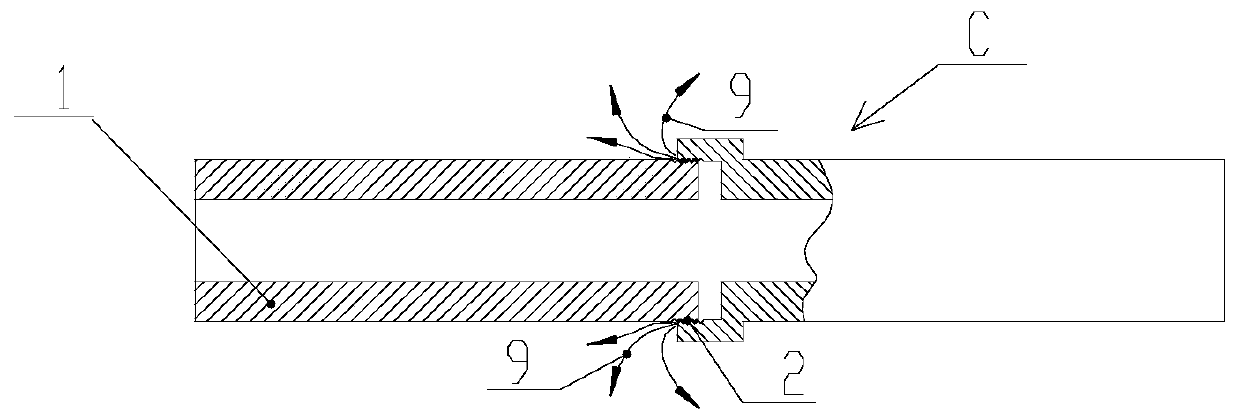

[0050] The online repair system and repair method of the pipeline assembly after seal failure of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0051] Such as Figure 5As shown, the on-line repair system after the seal failure of the pipeline assembly of the present invention includes several high-pressure pipelines 1 connected end to end to form a material delivery pipeline, and each two adjacent high-pressure pipelines 1 are connected to each other through a connecting component. Thus forming a sealed connection structure, the connection assembly is a manual valve connection assembly A or an electric valve connection assembly B or a threaded connection assembly C or a flange connection assembly D, and each of the sealing connection structures passes through a bag-type sealing diaphragm 6 for sealing, the edge 25 of each of the bag-type sealing diaphragms 6 is sealed and fixed on the outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com