Anthraquinone hydrogen peroxide production device

A production device, a technology for hydrogen peroxide, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., to achieve good heat transfer effect and low consumption , The effect of saving operating costs and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

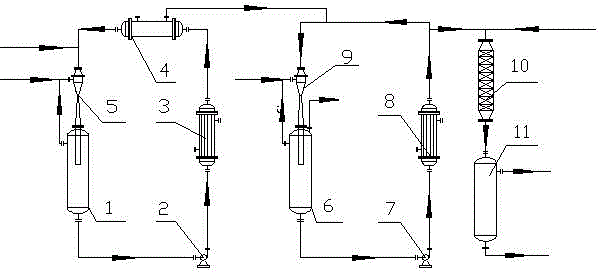

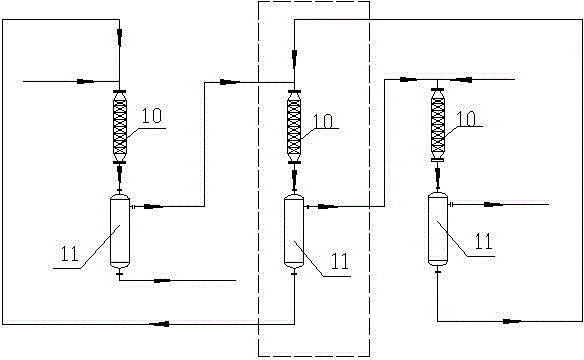

[0027] Such as figure 1 As shown, the hydrogen peroxide production device is composed of a hydrogenation reaction unit, an oxidation reaction unit and an extraction separation unit; it includes hydrogenation reactors 1, 1 # Circulation pump 2, 1 # Heat exchanger 3, cross-flow filter 4, 1 # Injector 5, oxidation reactor 6, 2 # Circulation pump 7, 2 # Heat exchanger 8, 2 # Ejector 9, static mixer 10 and oil-water separator 11; hydrogenation reactor 1 top installation 1 # Injector 5, the upper part of hydrogenation reactor 1 and 1 # A hydrogen circulation pipe is arranged between the injectors 5, a hydrogen inlet is arranged on the hydrogen circulation pipe, and the bottom of the hydrogenation reactor 1 passes through the pipe and the 1 # Inlet connection for circulation pump 2, 1 # The outlet of circulating pump 2 is connected with 1 through pipeline # Inlet connection for heat exchanger 3, 1 # The outlet of the heat exchanger 3 is connected to the inlet of the cross-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com