Intelligent furniture packaging production line

A smart packaging and production line technology, applied in packaging, packaging machines, packaging protection, etc., can solve problems such as unsuccessful installation, numerous parts, and increased labor intensity of packaging workers, so as to achieve safe production and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

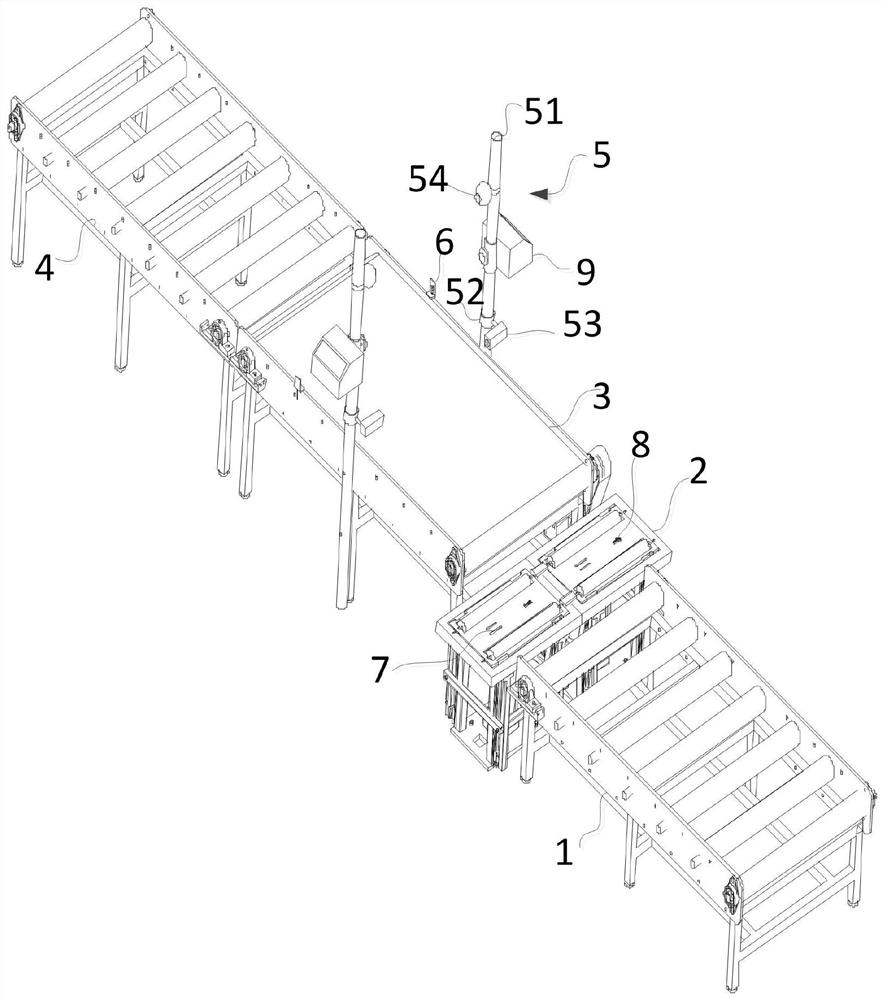

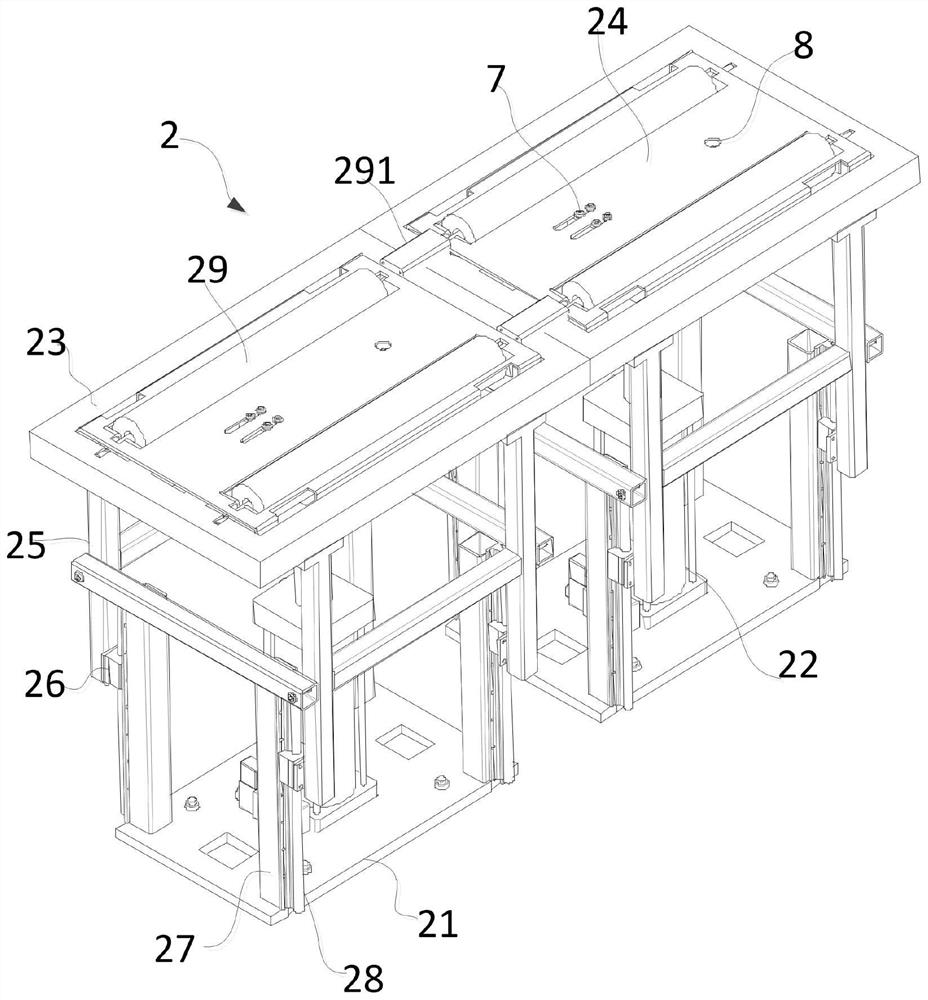

[0020] Example 1, such as figure 1 , figure 2 As shown, this embodiment aims to provide a furniture intelligent packaging production line, which provides convenience for furniture packaging and inspection, and at the same time, achieves the purpose of reducing manpower. Therefore, in order to achieve the above purpose, the furniture intelligent packaging production line provided in this embodiment includes a furniture conveying device 1, a furniture quality inspection workbench 2 and a packaging conveying device arranged in sequence along the moving direction of the furniture. The above structure is an existing common structure. In addition, in order to reduce power equipment, existing packaging lines often utilize the cooperation of gravity and height difference to realize conveying. Therefore, the height of the packaging conveying device is higher than that of the furniture conveying device 1 .

[0021] In order to realize the coding function, in this embodiment, a monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com