Constant temperature furnace for rotational viscometer

A technology of constant temperature furnace and viscometer, applied in the field of constant temperature furnace, can solve the problems of large thermal inertia, poor temperature control effect, unreasonable design of constant temperature furnace, etc., and achieves good heating uniformity, improved accuracy, and small thermal inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

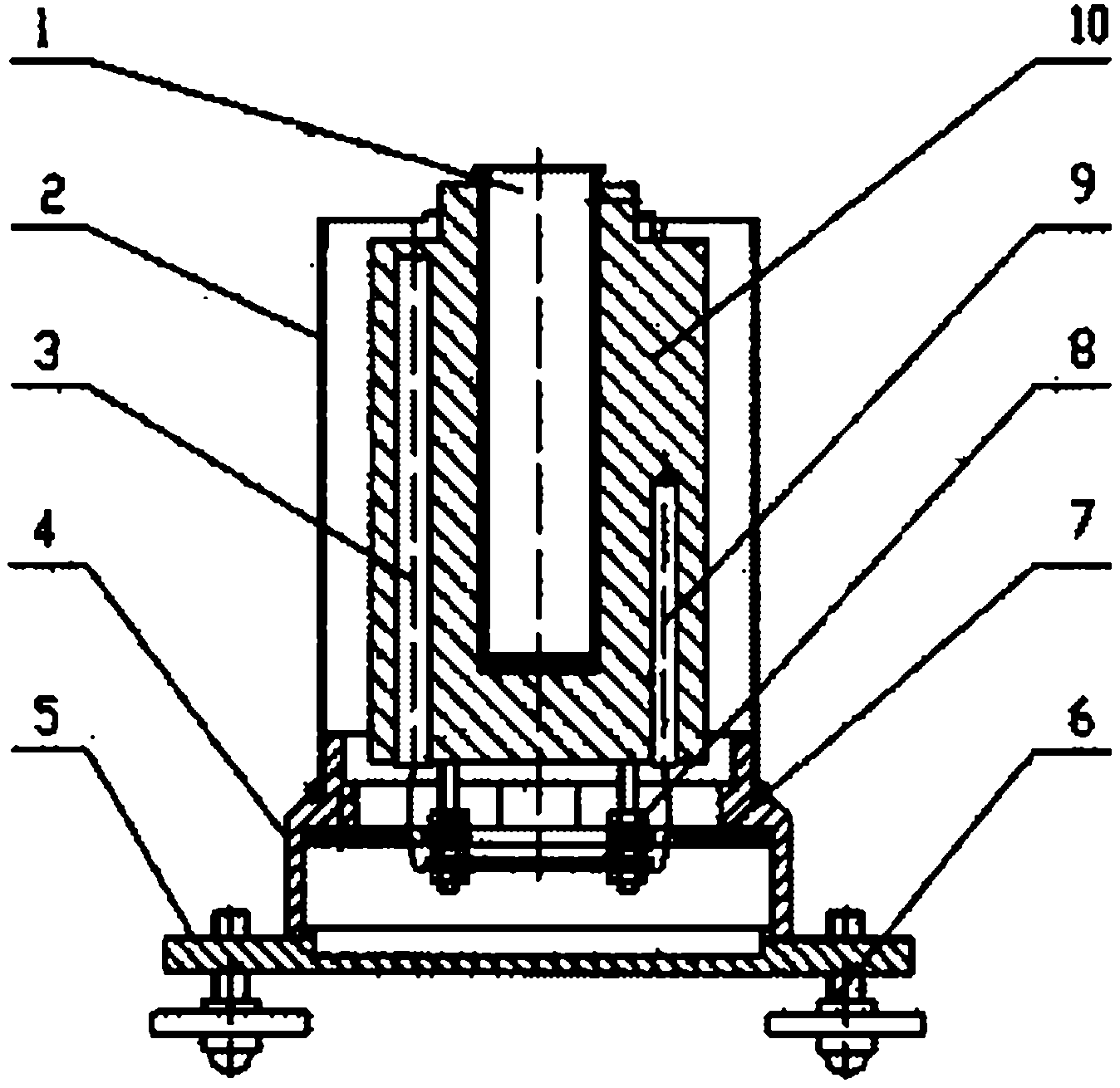

[0015] see figure 1 , in order to better understand the technical solution of the present invention, the following specific embodiments are described in detail in conjunction with the accompanying drawings:

[0016] see figure 1 , in the present embodiment, a constant temperature furnace for a rotary viscometer of the present invention includes a furnace body part and a control part, wherein the furnace body part includes a furnace body 10, a protective cover 2, a heat shield 7, and a terminal block 8 , temperature sensor 9, four electric heating rods 3, base 4, base plate 5 and leveling foot 6. The control section includes a controller.

[0017] A hearth is arranged at the center of the furnace body 10, and the hearth is used to place the holding cylinder 1 for containing the test liquid on the rotational viscometer. The storage container 1 can be conveniently put into or taken out from the furnace.

[0018] A temperature sensor 9 and four electric heating rods 3 are inse...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap