Fan plate type corrugated heat exchanger

A heat exchanger and corrugated technology, applied in the field of fan plate corrugated heat exchangers, can solve the problems that fan coil heat exchangers cannot be widely used, the coil heat exchange area is small, and the coil design space is large. Installation cost, large heat exchange contact area, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

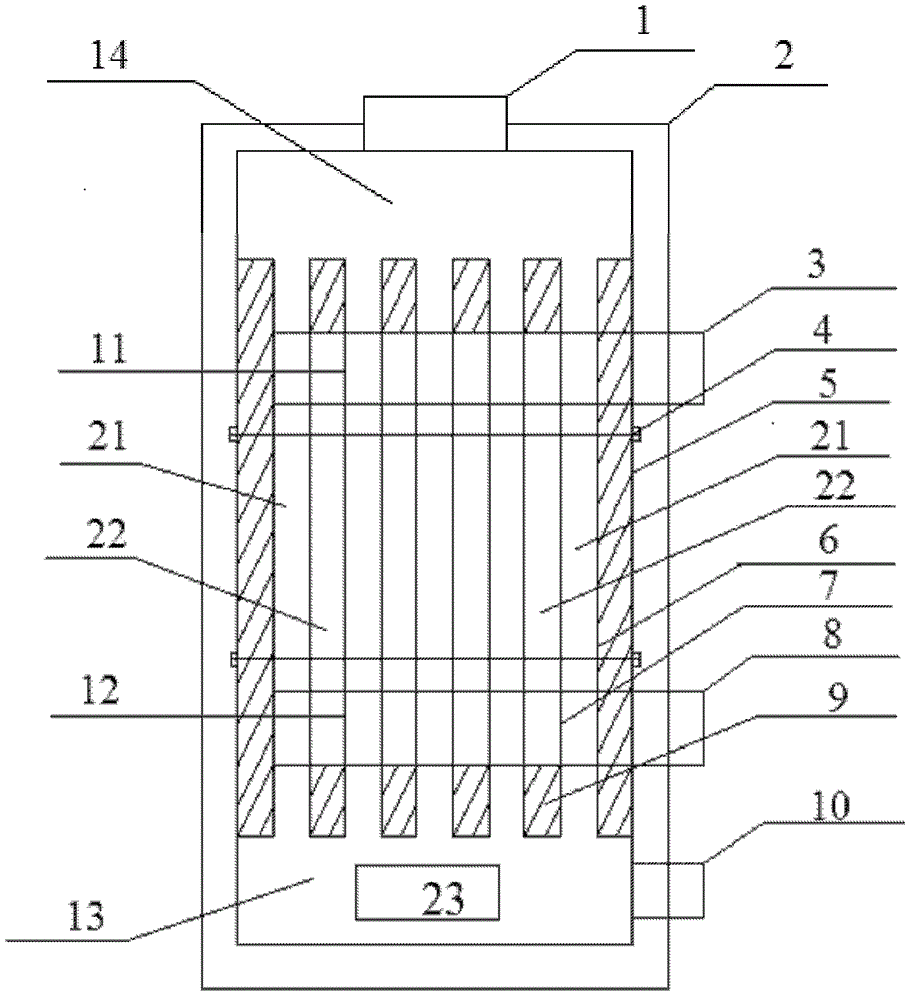

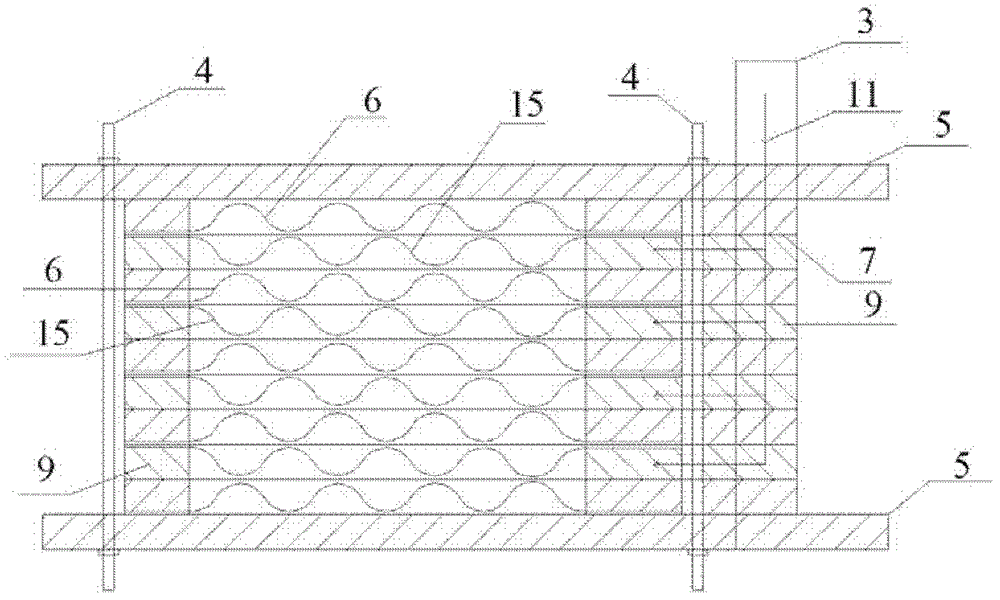

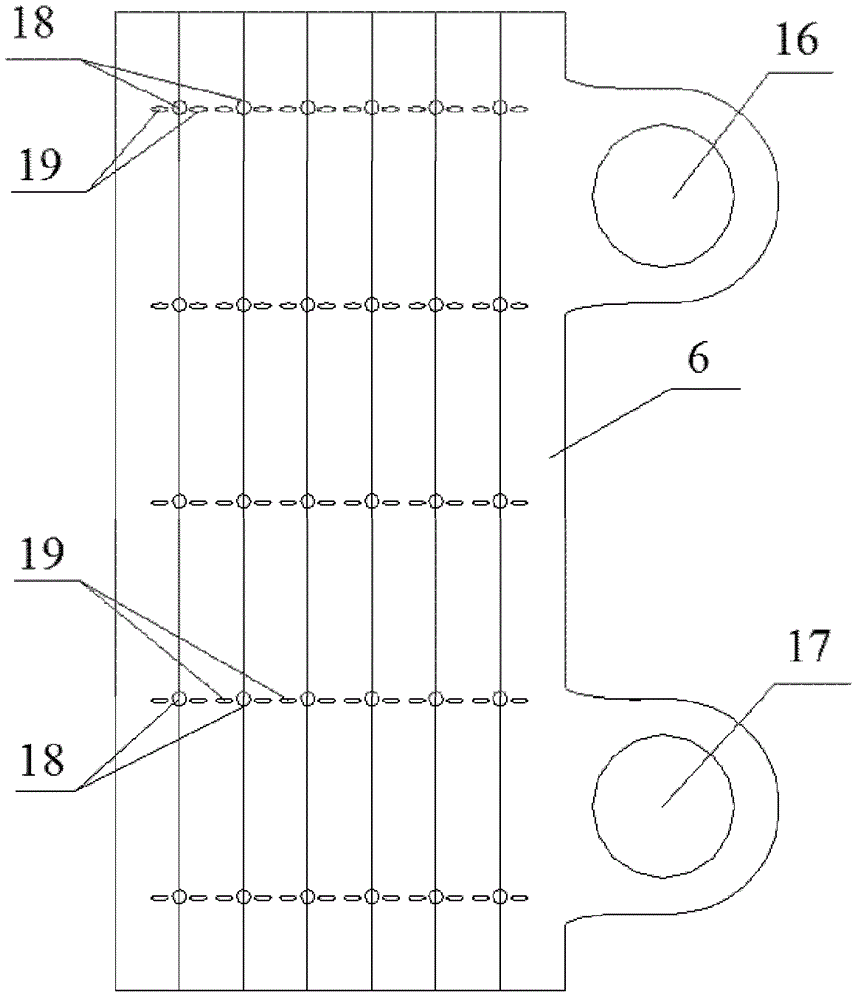

[0032] Such as figure 1 and figure 2 As shown, the fan plate type corrugated heat exchanger includes several corrugated ventilation plates 6 and several corrugated water passing plates 15, which are arranged at intervals with each other. Every two adjacent corrugated ventilating plates 6 and corrugated water passing plates 15 are separated by a separating plate 7 . All corrugated ventilating plates 6 , separating plates 7 and corrugated water passing plates 15 are fixed between two fixing plates 5 . The corresponding side of fixed plate 5, corrugated ventilation plate 6 and separating plate 7 has two protruding, consistent circular holes respectively, i.e. water inlet 16 and water outlet 17 (as image 3 , Figure 5 and Figure 6 shown in ). There is a sealing structure 9 between the corrugated ventilation plate 6 and the corrugated wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com