High speed bearing tester

A high-speed bearing and testing machine technology, applied in the direction of mechanical bearing testing, etc., can solve the problem of low precision of bearing testing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

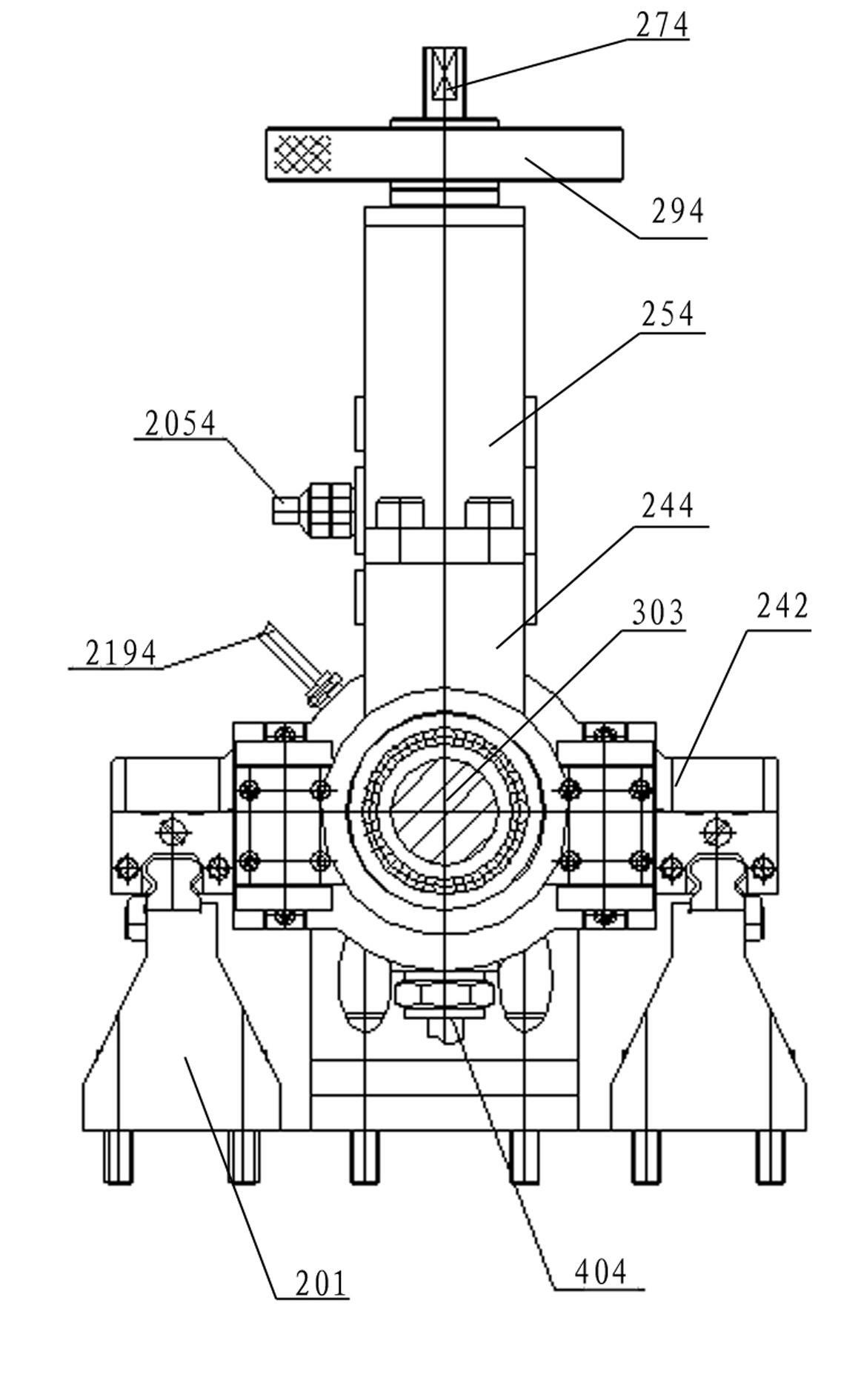

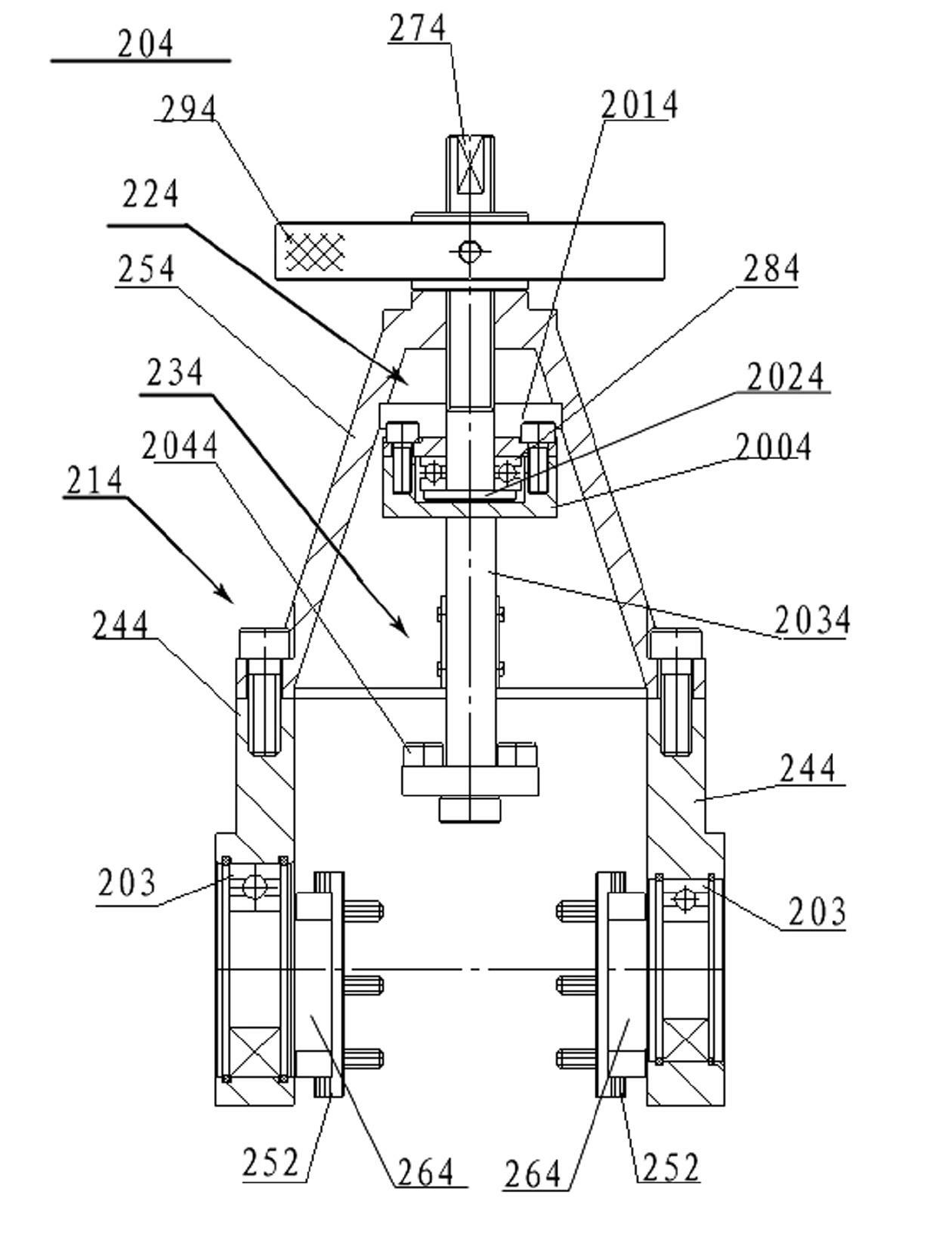

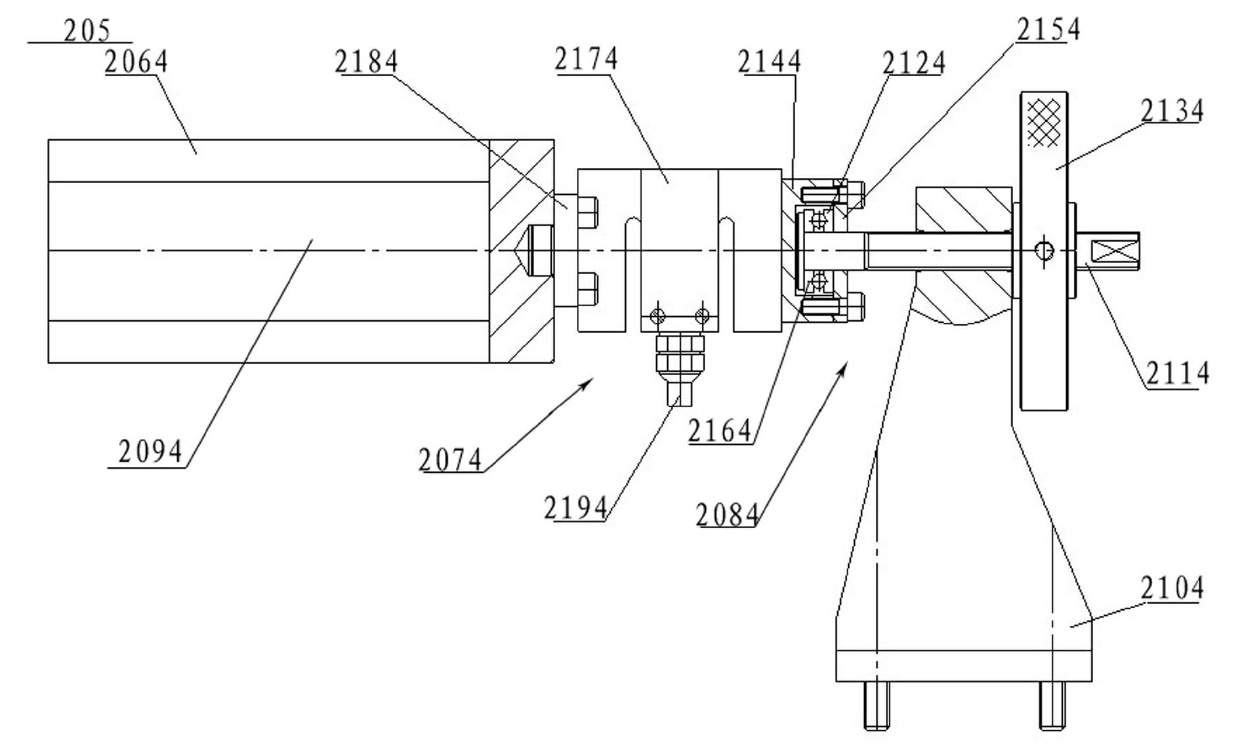

[0032] The embodiment of high-speed bearing testing machine of the present invention: as Figure 1 to Figure 8 As shown, the testing machine includes a test spindle 1, a loading device 2, an inner ring cooling structure 3, an outer ring cooling structure 4, and an electric spindle device 5, wherein the electric spindle device 5 and the loading device 2 are respectively arranged on the left and right sides of the test spindle 1 At both ends, the inner ring cooling structure 3 is set on the test spindle 1 , and the outer ring cooling structure 4 is set on the loading device 2 .

[0033] The loading device 2 is composed of a base 201 , a bearing housing 202 , a test bearing 203 , a radial loading device 204 and an axial loading device 205 . Wherein, there are two accompanying test bearings 203, and are arranged on the left and right sides of the bearing seat 202 respectively. The bearing seat 202 is composed of an inner carrier 212 fixed on the outer ring of the test bearing 6, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com