Anti-rollover device used for high-speed driving maneuverability test and anti-locking test for car

A high-speed driving and maneuverability technology, which is applied to measurement devices, vehicle testing, and machine/structural component testing. problems, to achieve the effect of good force, protection and safety, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

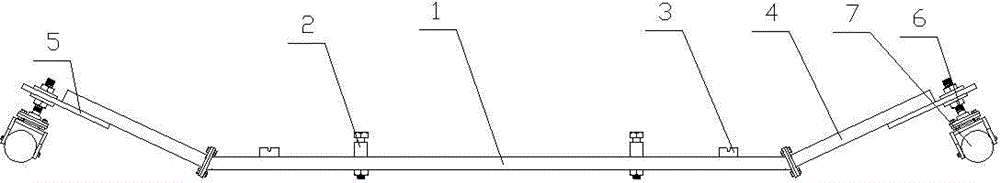

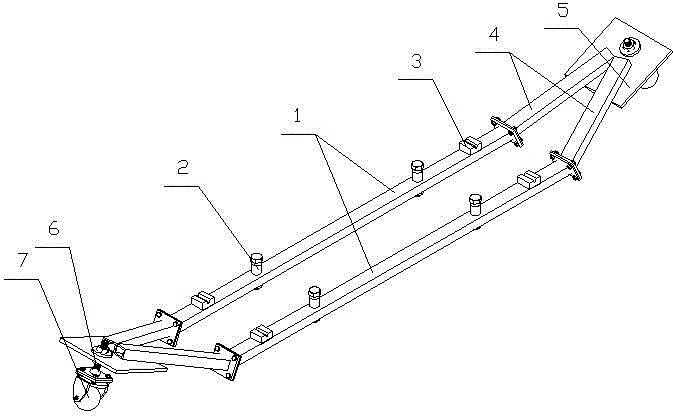

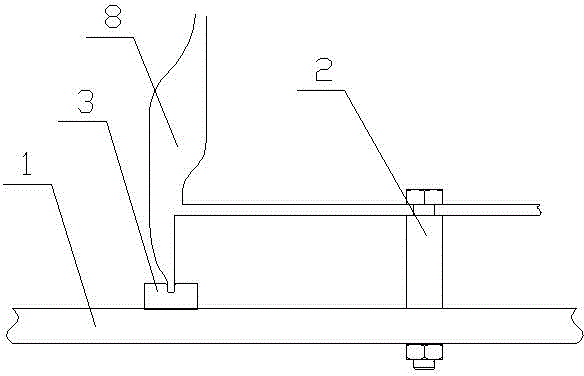

[0025] see figure 1 , figure 2 and image 3 , the anti-rollover device for high-speed car handling test and anti-lock braking test includes two parallel beams 1, the beam 1 is a hollow flat steel pipe section, the length is 1800 mm, and the distance between the two beams is 650-700 mm . Two upright fixed sleeves 2 are evenly distributed in the middle of each beam 1, and the inner diameter of the fixed sleeves 2 is 40mm;

[0026] Mounting bolts are respectively installed in each fixed sleeve 2, and pads 3 are installed on the beams 1 outside the two fixed sleeves 2 respectively. The groove is perpendicular to the beam 1. One end of the two beams 1 is connected to the two ends of the V-shaped frame 4, and the other end is connected to the two ends of another V-shaped frame 4, and the outside of the V-shaped frame 4 is tilted upwards, so that the gap between the V-shaped frame 4 and the cross beam 1 form an included angle of 160 degrees; the height of the V-shaped frame 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com