Adjustable fixture used for clamping surface plate base plate

An adjustable, flat-panel technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as increasing costs, achieve reliable clamping, convenient adjustment, and reduce the number of requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

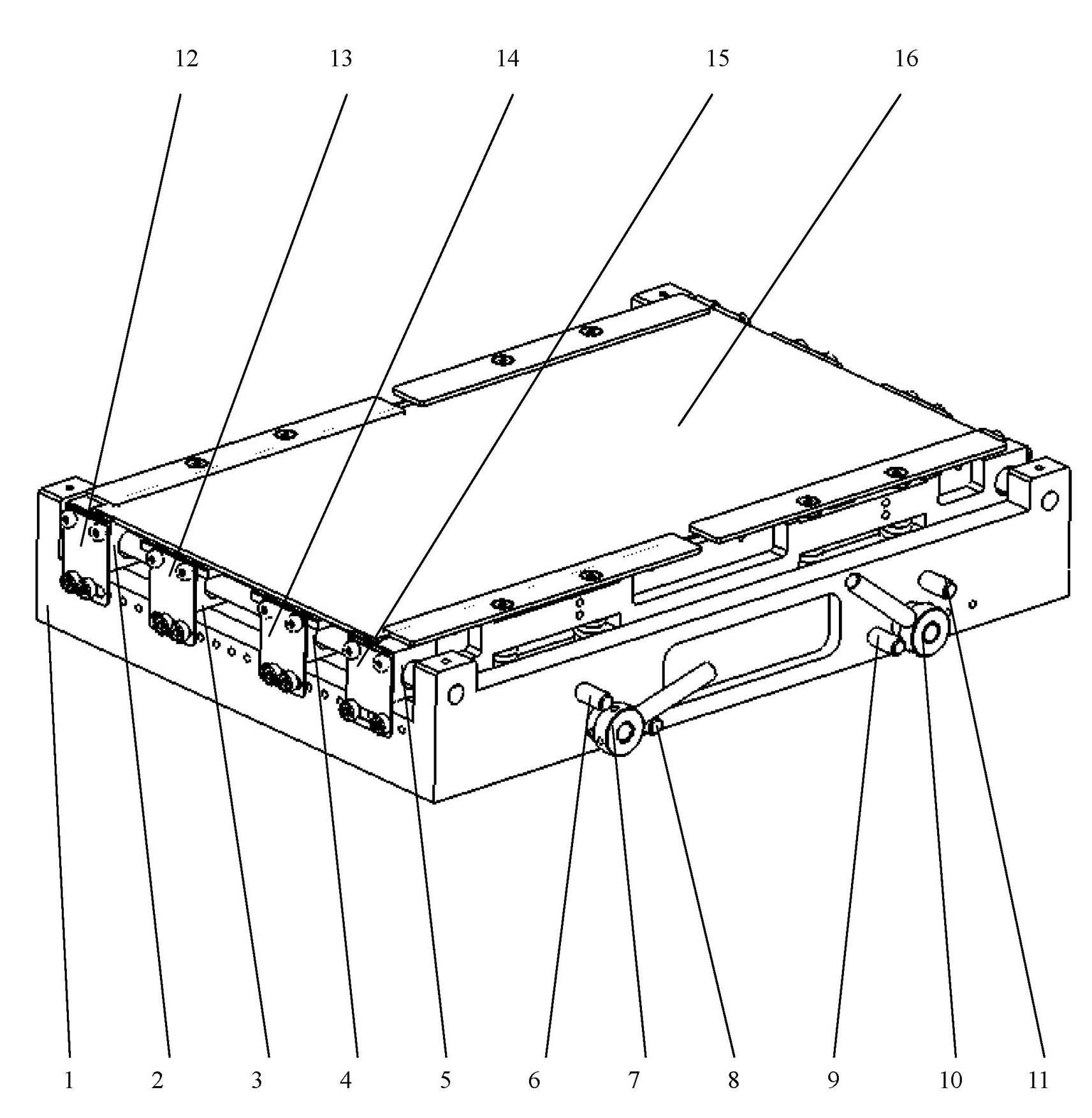

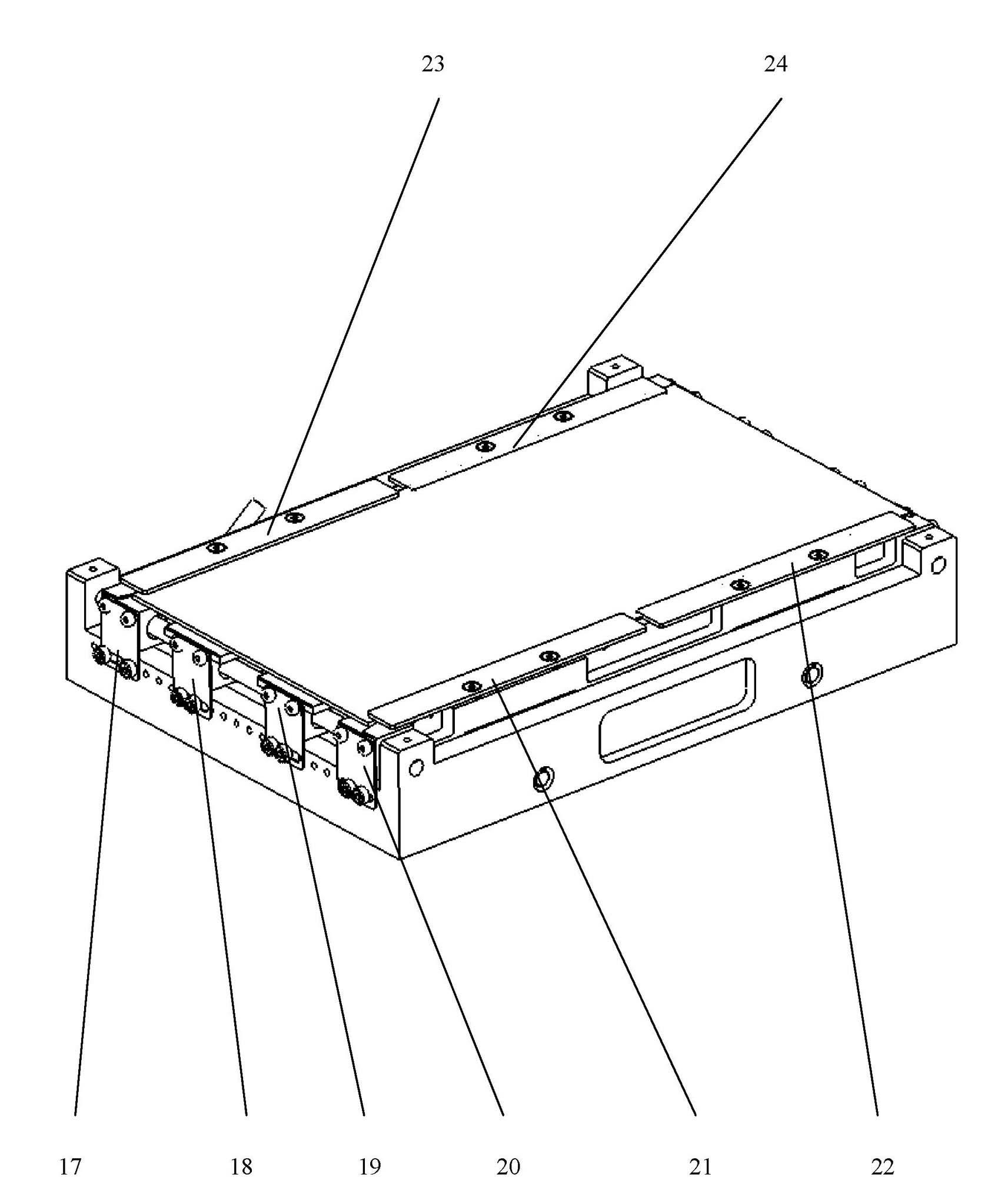

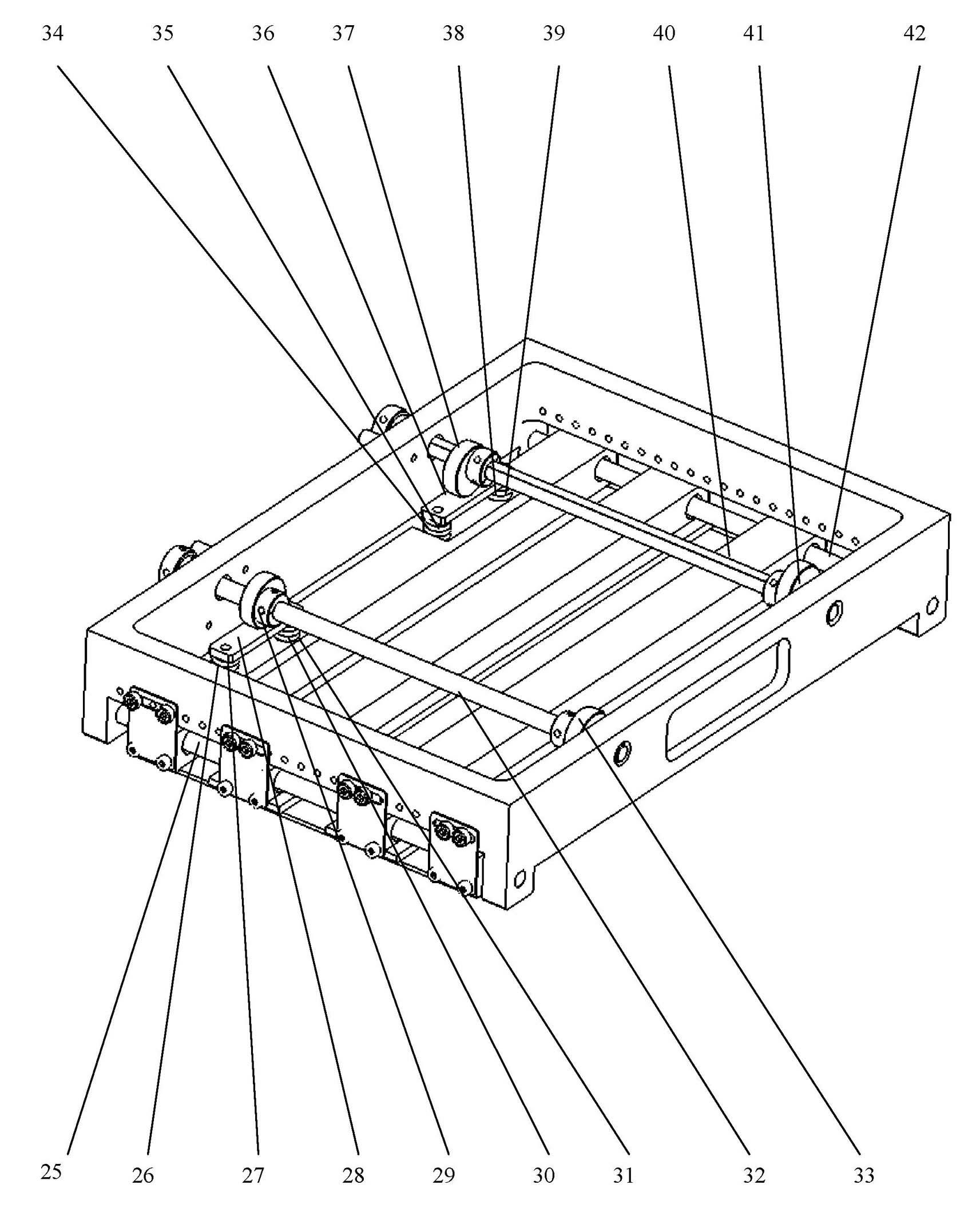

[0025] as attached Figure 1-6 As shown, it includes a base 1, which is characterized in that the front bearing strip 2, the front middle bearing strip 3, the rear middle bearing strip 4 and the rear bearing strip 5 are placed in the transverse direction of the base 1, and the described Both ends in the longitudinal direction of the base 1 are provided with a left guide shaft 25 and a right guide shaft 42, the two ends of the front bearing strip 2, the front middle bearing strip 3, the rear middle bearing strip 4 and the rear bearing strip 5 Shaft holes are provided and respectively inserted into the left guide shaft 25 and the right guide shaft 42;

[0026] Four guide holes are uniformly arranged in the transverse direction on the outer end of the rear bearing material strip 5, and the left rear guide shaft 1 26, the left rear guide shaft 2 30, the right rear guide shaft 1 are sequentially inserted in the guide holes. 34 and right rear guide shaft two 38;

[0027] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com