Method for automatically controlling strip steel edge drop of cold tandem mill

A technology of cold tandem rolling mill and edge drop, applied in the field of control, to achieve the effect of ensuring control effect and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

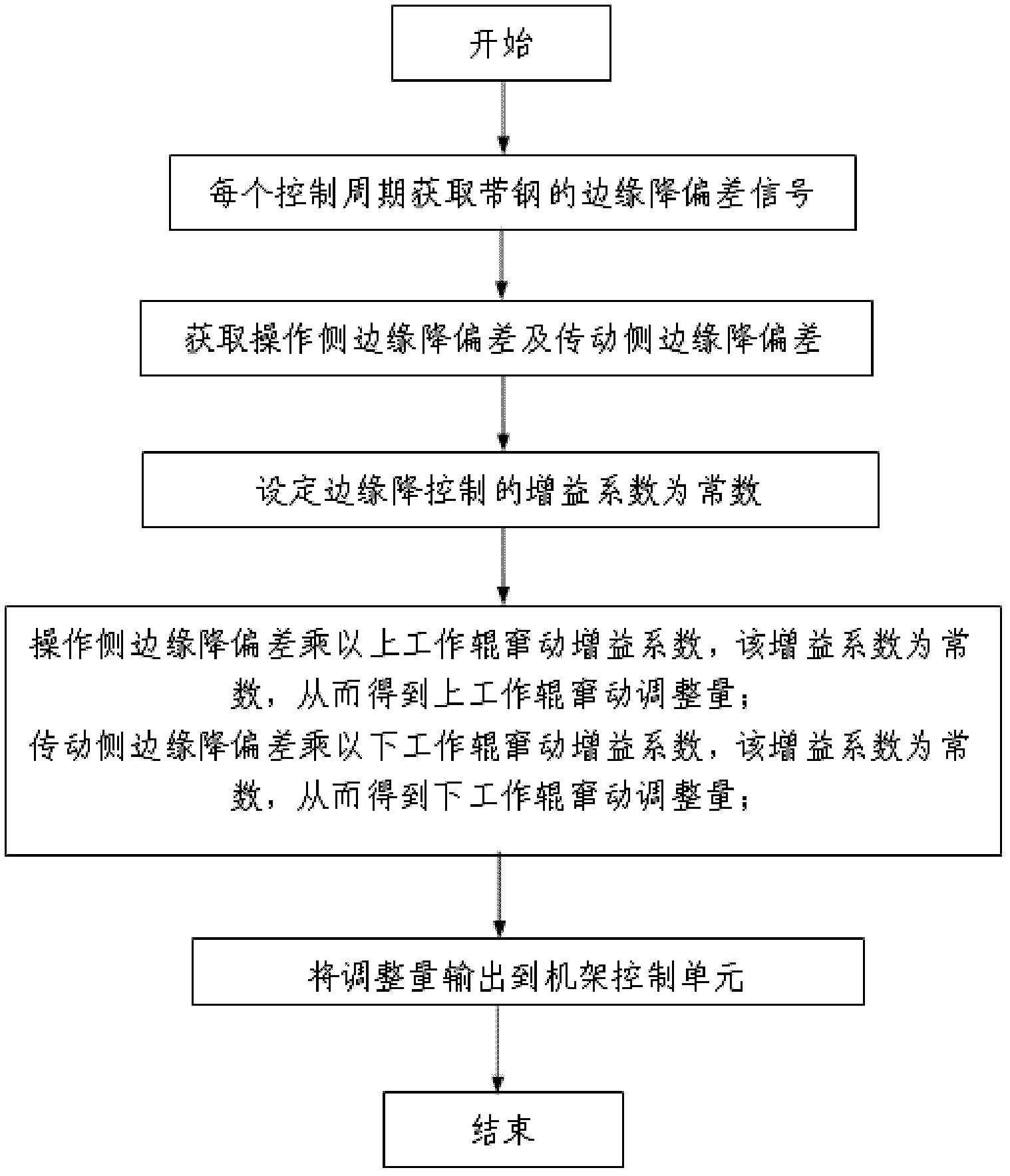

Method used

Image

Examples

Embodiment 1

[0109] Before the edge drop control is put into operation, first test the edge drop regulation ability of the first frame 5a, the second frame 5b, and the third frame 5c for symmetrical work roll movement, and obtain the gain coefficient: k S1 =0.03,k S2 =0.02,k S3 =0.02;

[0110] Drop the target edge and the gain factor k S1 , k S2 , k S3 Stored in the database on the edge drop controller 3. Carry out the following calculations according to the control period (T=0.75s) with the edge drop automatic control program.

[0111] The actual edge drop signal is received from the computer 2, and the actual edge drop signal is subjected to sliding average processing to obtain the actual edge drop average value. Subtract the target edge drop value from the actual edge drop average value to obtain the strip edge drop deviation value. At this time, the obtained edge drop deviation value on the operating side and the edge drop deviation value on the transmission side are respectively...

Embodiment 2

[0121] Before the edge drop control is put into operation, first test the edge drop regulation ability of the first frame 5a, the second frame 5b, and the third frame 5c for symmetrical work roll movement, and obtain the gain coefficient: k S1 =0.03,k S2 =0.02,k S3 =0.02;

[0122] Drop the target edge and the gain factor k S1 , k S2 , k S3 Stored in the database on the edge drop controller 3. Carry out the following calculations according to the control period (T=0.75s) with the edge drop automatic control program.

[0123] The actual edge drop signal is received from the computer 2, and the actual edge drop signal is subjected to sliding average processing to obtain the actual edge drop average value. Subtract the target edge drop value from the actual edge drop average value to obtain the strip edge drop deviation value. At this time, the obtained edge drop deviation value on the operating side and the edge drop deviation value on the transmission side are respectively...

Embodiment 3

[0133] Before the edge drop control is put into operation, first test the edge drop regulation ability of the first frame 5a, the second frame 5b, and the third frame 5c for symmetrical work roll movement, and obtain the gain coefficient: k S1 =0.05,k S2 =0.06,k S3 =0.06;

[0134] Drop the target edge and the gain factor k S1 , k S2 , k S3 Stored in the database on the edge drop controller 3.

[0135] The edge drop automatic control program is calculated as follows according to the control period (T=3s).

[0136] The actual edge drop signal is received from the computer 2, and the actual edge drop signal is subjected to sliding average processing to obtain the actual edge drop average value. Subtract the target edge drop value from the actual edge drop average value to obtain the strip edge drop deviation value. At this time, the obtained edge drop deviation value on the operating side and the edge drop deviation value on the transmission side are respectively: a 1 =-8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com