Method for processing exhaust pipe flange and special die thereof

A processing method and mold technology, applied in the field of mechanical processing, can solve the problems of low production efficiency, long processing time and high cost, and achieve the effects of simple structure, saving processing cost and saving labor hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

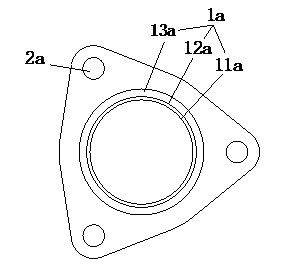

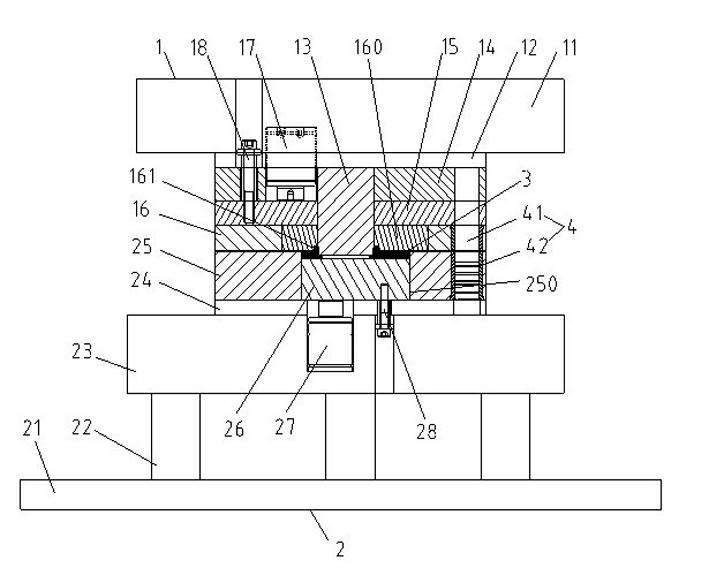

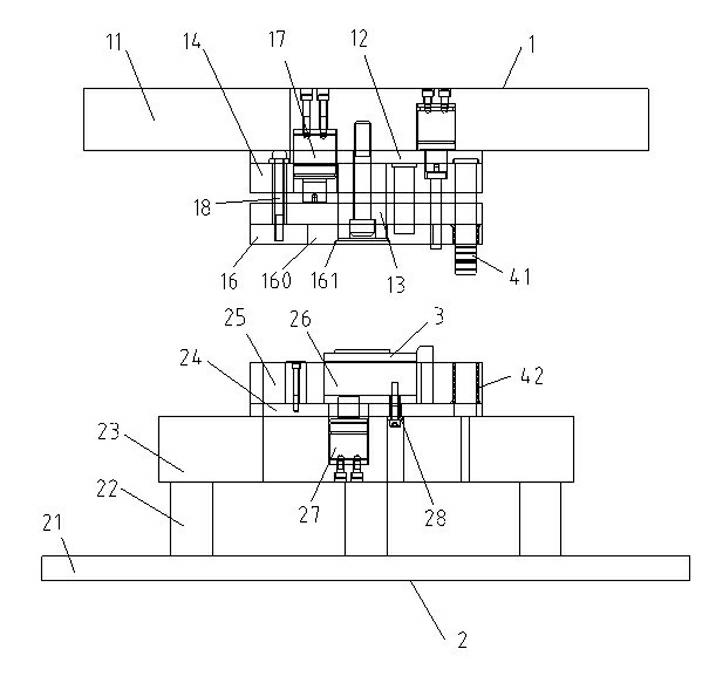

[0023] The processing method of the automobile exhaust pipe flange of the present invention is all processed by the method of die stamping, without turning machining allowance. The specific process is as follows: blanking - punching - pumping - shaping rounded corners - reverse extrusion and whole platform - secondary punching.

[0024] In the blanking process, the general blanking mold is used to blank according to the product structure.

[0025] In the punching process, a general punching die is used to punch out the central hole and the assembly hole.

[0026] Hole pumping process, the main process parameters are adjusted by the general hole pumping die; the main process parameters are: the inner diameter of the central hole Φ54.00±0.05mm, the outer diameter of the turned hole Φ65.00±0.05mm, and the rounded corner of the outer contour R2 ±0.5mm, the bottom fillet radius of the inner hole of the central hole is R0.3±0.05mm. After the hole is drawn, the bottom of the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com