Steel ladle capping device

A ladle and rotating arm technology, applied in metal processing equipment, casting melt container, casting equipment, etc., can solve problems such as decoupling, potential safety hazards, decoupling of the ladle cover, etc., to achieve easy operation, prevent decoupling of the hanging shaft, and maintain movement consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

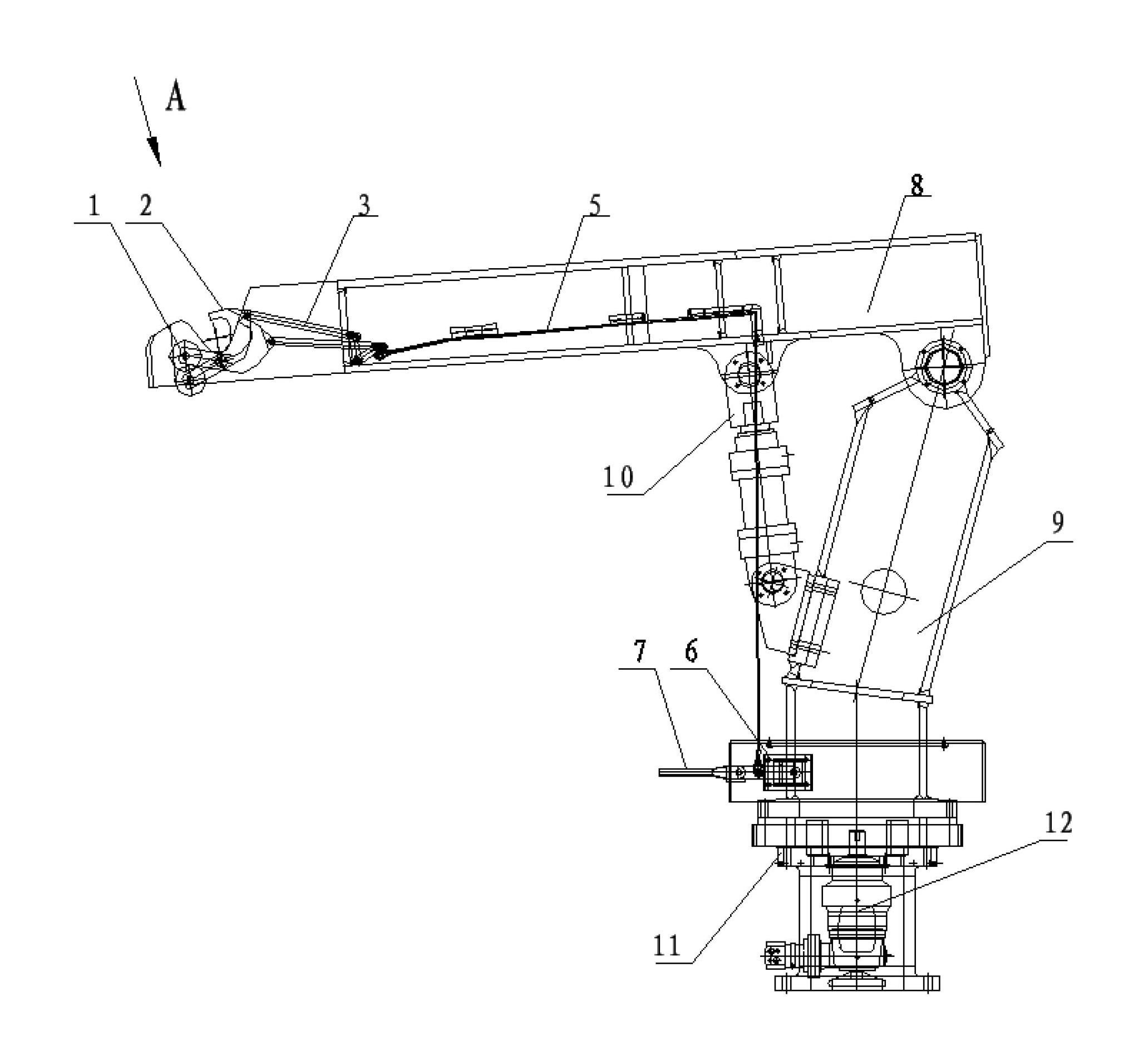

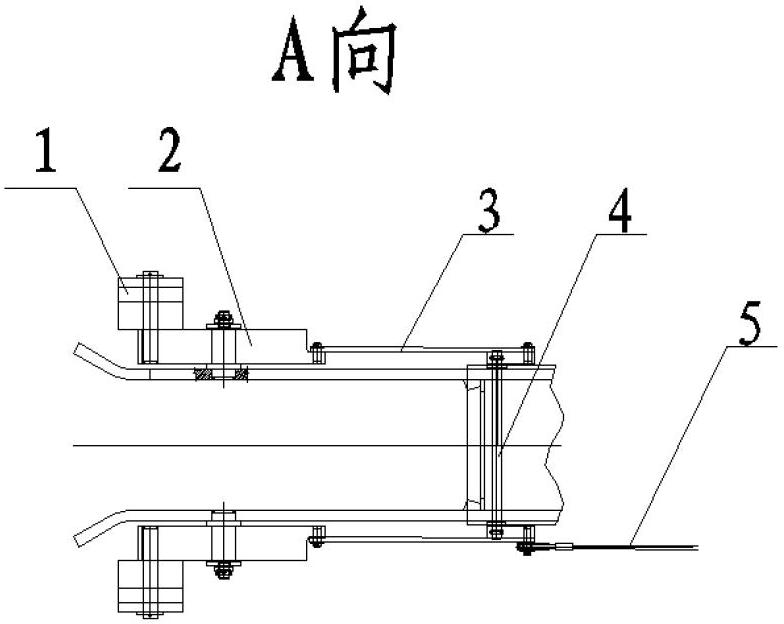

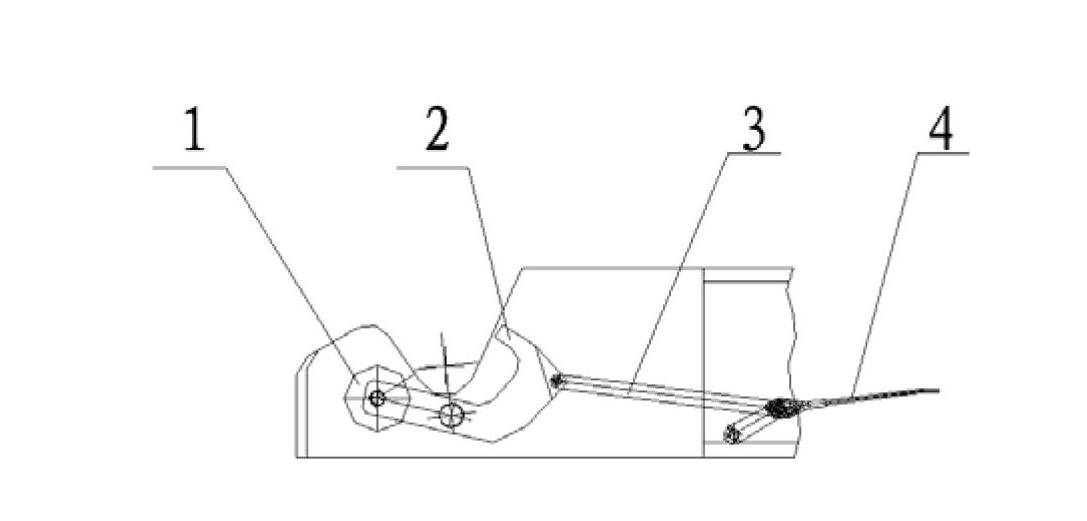

[0020] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-2 As shown, a ladle capping device includes a rotating arm 8, a rotating column 9, a column 11, a lifting cylinder 10 and a rotary motor 12. The front end of the rotating arm 8 has a hook, and its rear end is connected to the upper end of the rotating column 9. Connection, the middle position realizes the lifting function by connecting the lower part of the lifting cylinder 10 with the rotating column 9, the lower end of the rotating column 9 is connected with the upper section of the column 11, and realizes the turning function through the rotary motor 12, and the lower end of the column 11 is installed on the rotary platform The ladle capping device also includes a counterweight 1, a locking hook 2, a connecting rod 3, a connecting shaft 4, a steel wire rope 5, a support seat 6 and a handle 7, and both sides of the hook at the front end of the rotating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com