Novel demolding machine

A demoulding machine and demoulding frame technology, applied in the direction of wood compression, etc., can solve the problems of low demoulding efficiency, mold deformation, and inability to demould multiple molds at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

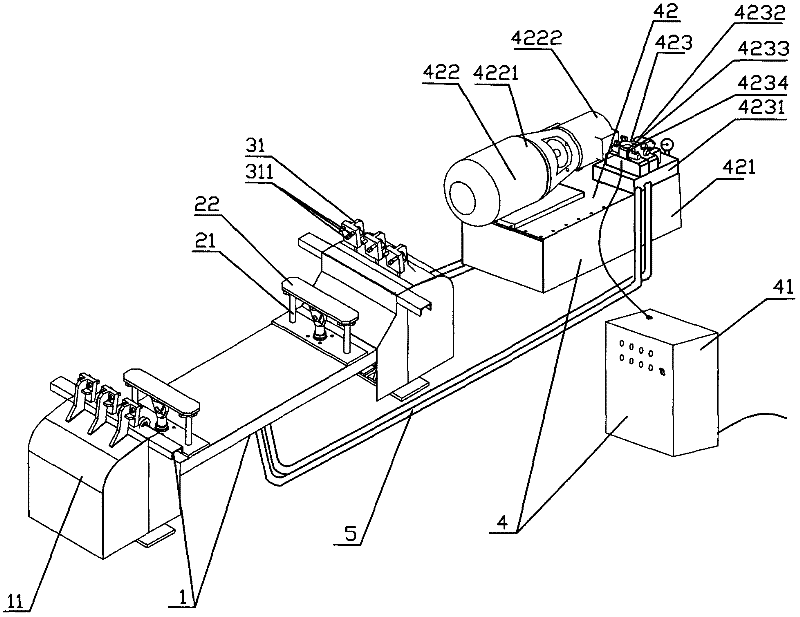

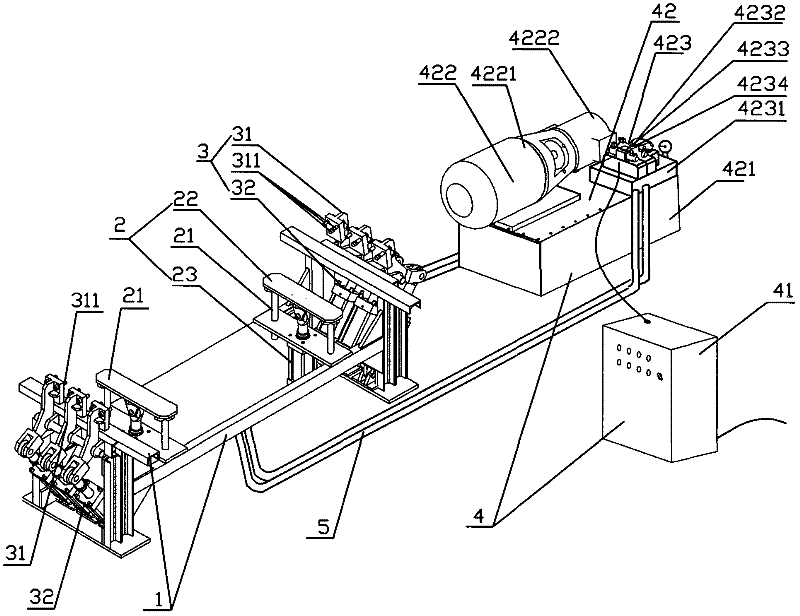

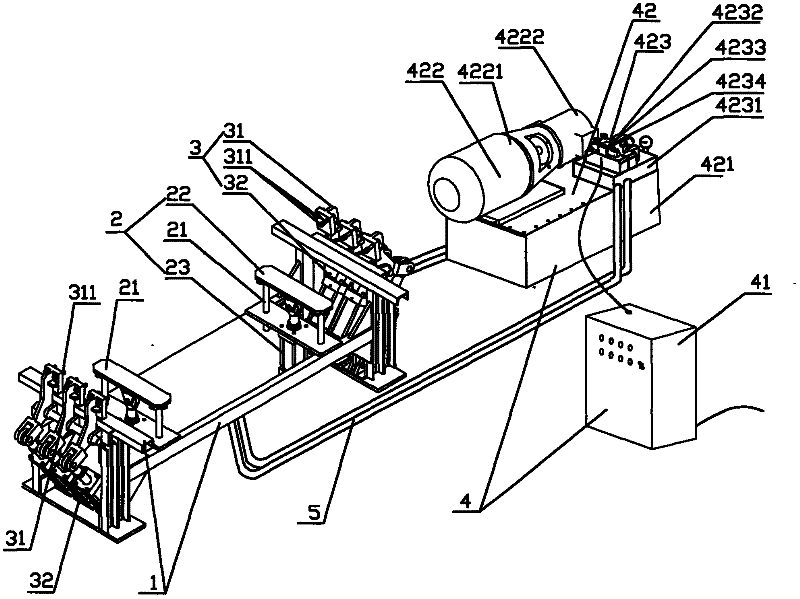

[0016] Such as figure 1 , figure 2 As shown, a new demoulding machine includes a demoulding frame 1, a lifting device that can lift the mold and the heavy bamboo square material in the mold 2, and a clamping device that can block or loosen the heavy bamboo square material in the mold 3. A driving device 4 capable of operating the lifting device 2 and the clamping device 3 , the lifting device 2 is arranged inside the demoulding frame 1 , and the clamping device 3 is arranged at both ends of the demoulding frame 1 . The lifting device 2 and the clamping device 3 are connected with the driving device 4 through the oil pipe 5 . Described lifting device 2 is made up of guide bar 21, jacking block 22 and the oil cylinder one 23 that can be driven by driving device 4. The clamping device 3 includes three cranks 31 , three claws 311 arranged on each crank 31 , and an oil cylinder 2 32 capable of driving the cranks 31 to move. Described driving device 4 comprises controller 41 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com