Battery box structure of electric bicycle

A technology for electric bicycles and battery boxes, which is applied to vehicle components, rider driving, transportation and packaging, etc. It can solve problems such as loose structure, easy loss, and impact on driving safety, and achieve increased visual impact and high productivity , The effect of easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

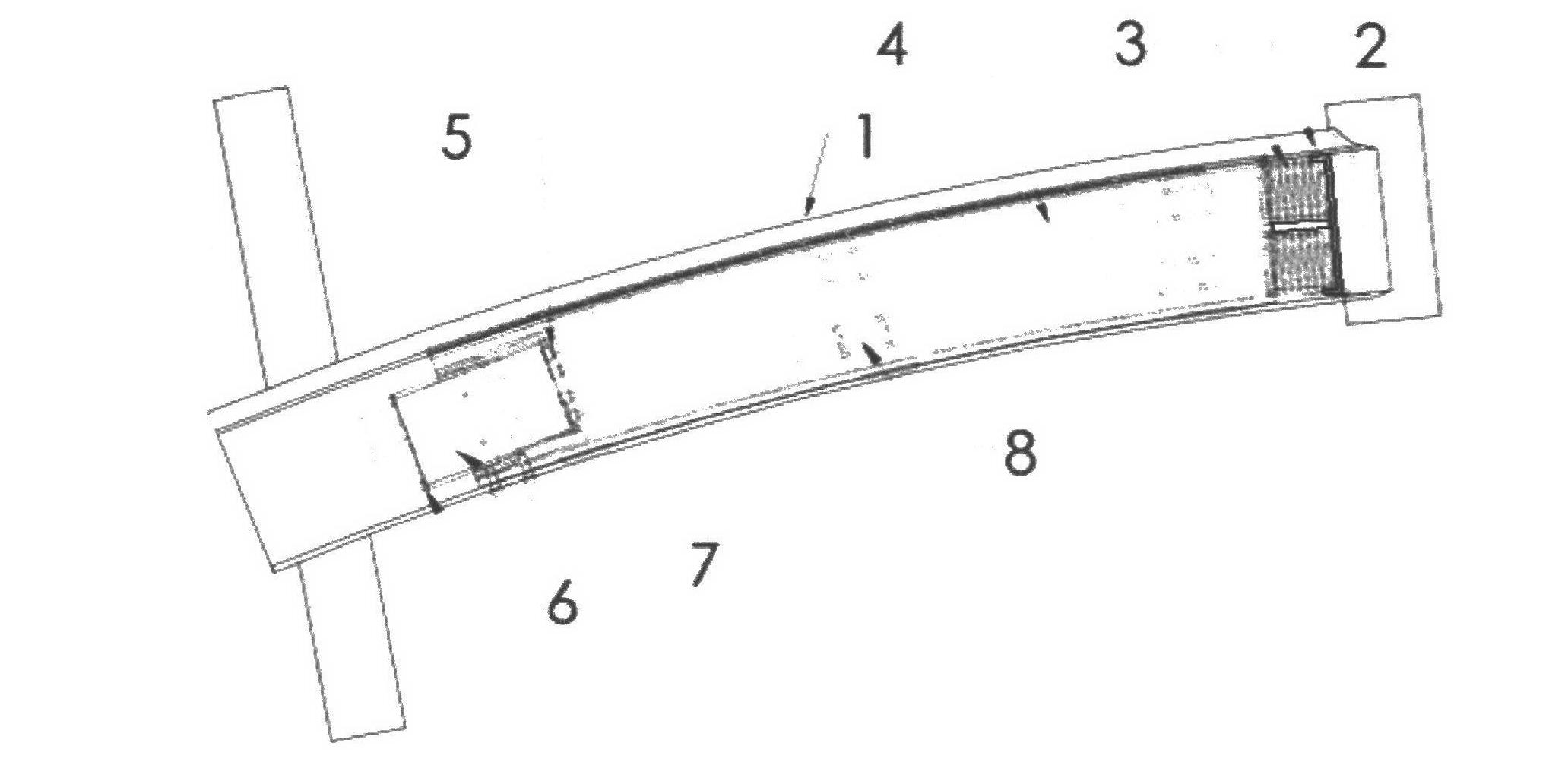

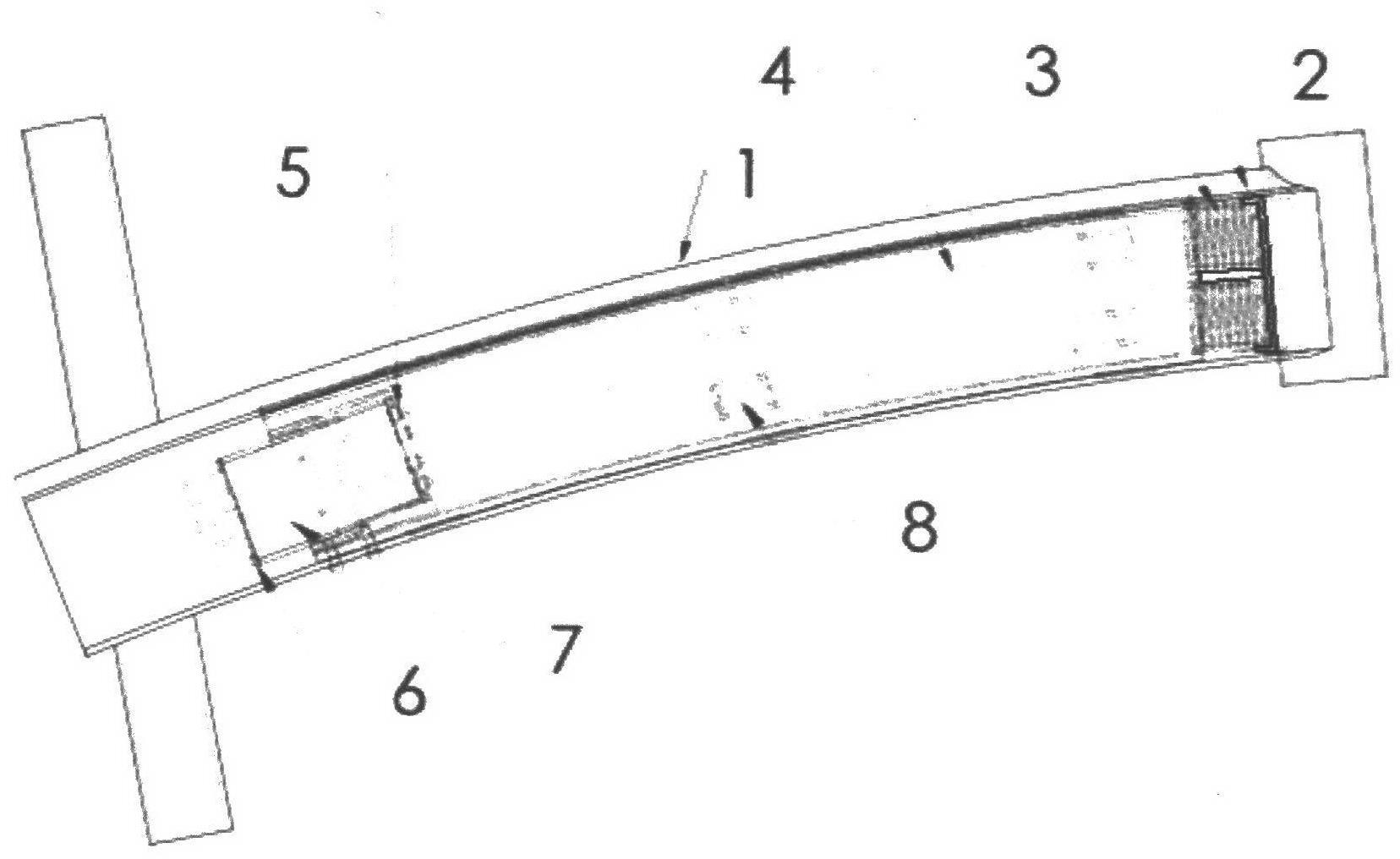

[0018] see figure 1 As shown, a battery box structure of an electric bicycle includes a frame lower tube 1, a battery box 4 is placed in the vehicle frame lower tube 1; a spring 3 is connected to the front end of the battery box 4, and the spring 3 The inner front end of the lower tube 1 of the vehicle frame is fixed by the spring fixing plate 2; the rear end of the battery box 4 is fixed on the inner tail end of the lower tube 1 of the vehicle frame by screws, and the rear end of the battery box 4 is It is tightly connected with the controller 7 by screws, and the controller 7 is covered with a controller fixing plate 6; the shell of the battery box 4 is pasted with several strips of foam 8 for shock absorption.

[0019] Further, the downtube 1 of the vehicle frame is in an inclined upward structure, and the battery box 4 is in a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com