Embedded type sealing barrel cover and production method thereof

A technology of barrel lids and caps, which is applied in the direction of closure plugs, closures, closures with plugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (Embodiment 1, sealed bucket lid)

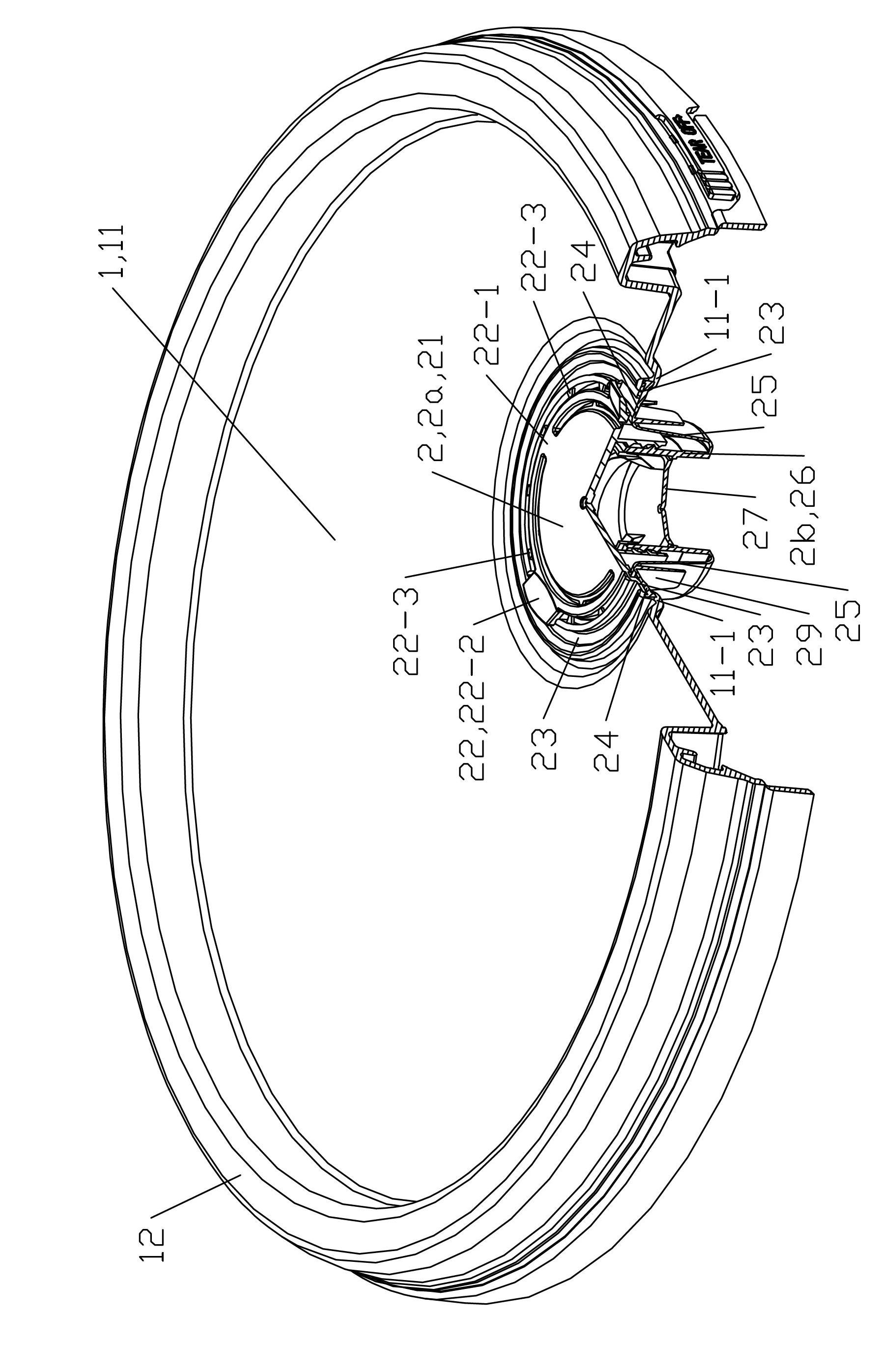

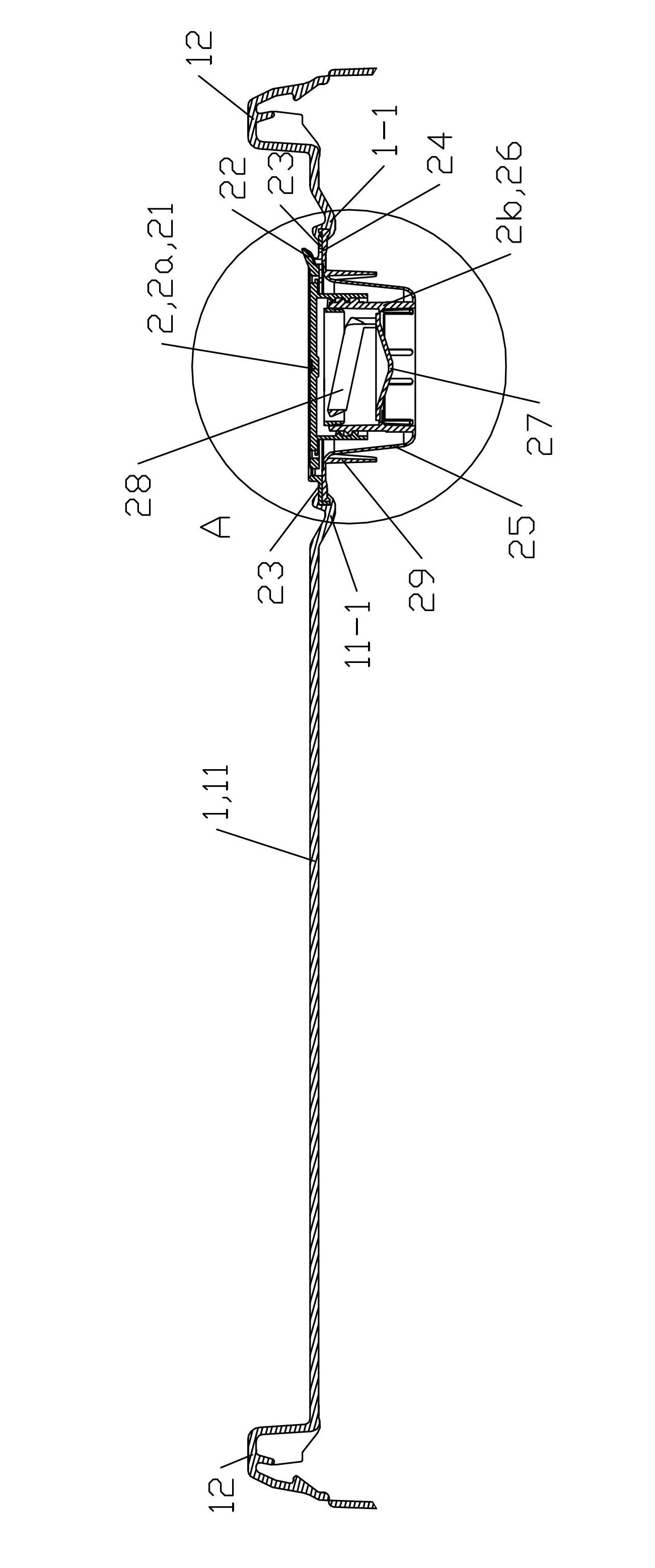

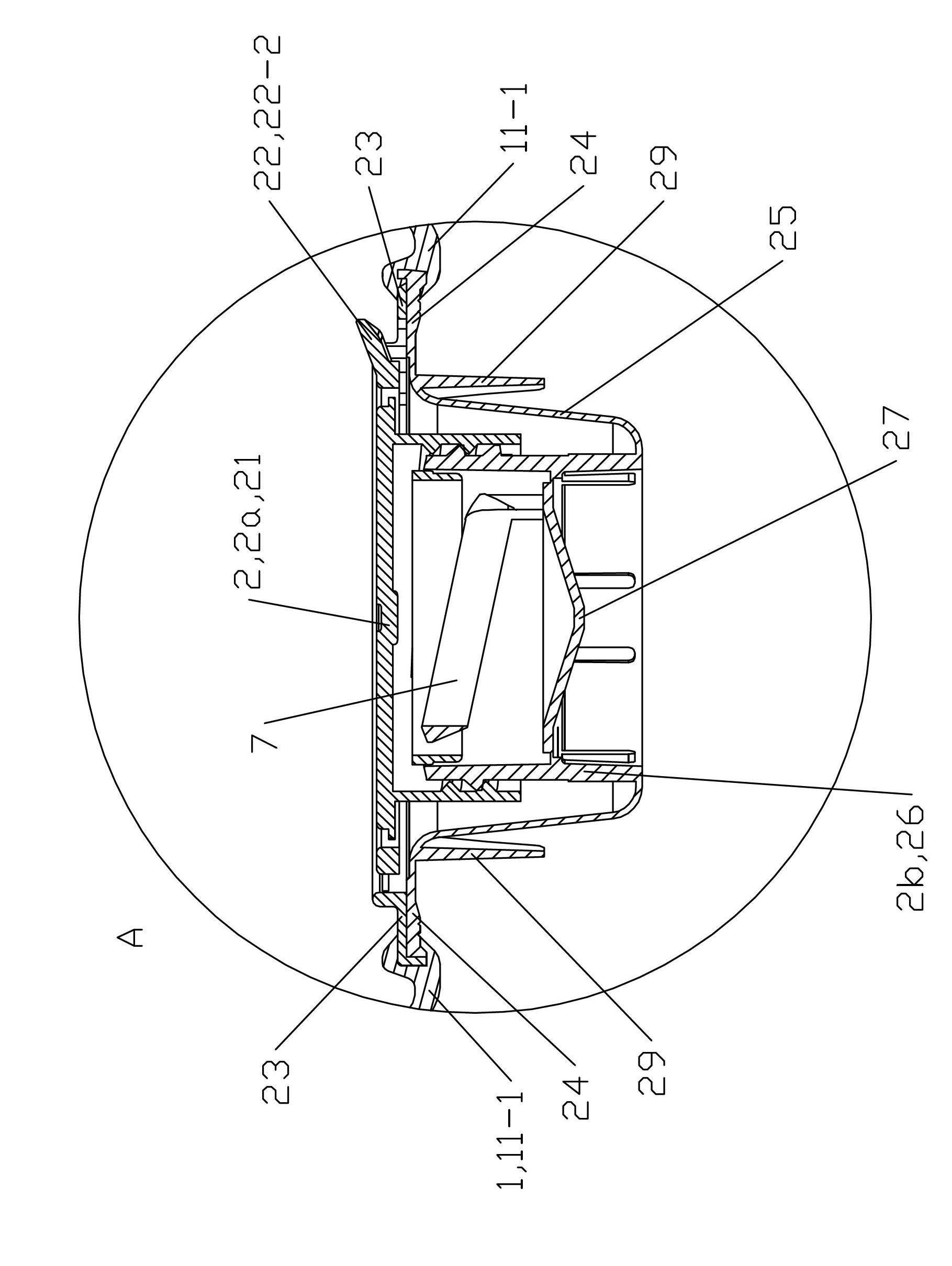

[0034] See Figure 1 to Figure 3, The embedded type sealed bung of the present embodiment is composed of a bung main body 1 and a sealant cover 2 . The lid main body 1 is made of polypropylene plastic, and includes a horizontally arranged main cover plate 11 that is substantially circular and an outer peripheral frame plate 12 connected to the outer periphery of the main cover plate 11 . The embedded type sealed barrel cover is a plastic product with a sealant cover 2 as an insert, the insert sealant cover 2 uses its outer peripheral edge as an embedded part, and the barrel cover main body 1 is the injection molding part of the insert plastic product. And by its main cover plate 11 around the embedded part of the sealant cover 2 for injection molding, so that the bung main body 1 is half-surrounded by its main cover plate 11 around the outer peripheral edge of the sealant cover 2 from the upper side, the outer side and the lower side...

Embodiment 2

[0046] (Example 2, manufacturing method)

[0047] The injection mold of the embedded type sealed bucket lid described in embodiment 1 is made of Figure 5 shown. The method for manufacturing the embedded type sealed bung obtained in Example 1 in this embodiment includes the following steps: ① Obtain the cap member 2a and the inner plug member 2b by injection molding respectively;

[0048] ② Screw the cap body 21 of the cap member 2a and the port portion 26 of the inner plug member 2b together to form the sealant cap 2;

[0049] ③The outer peripheral edge of the anti-theft ring 23 is tightly stacked on the outer peripheral edge of the skirt portion 24 of the inner plug member 2b;

[0050] ④ Put the sealant cover 2 into the cavity of the insert mold 3 of the manufacturing mold of the bung cover main body 1, and use the outer peripheral edge of the cap member 2a as the embedded part to inject the bung cover main body 1, and the sealant cover 2 The outer edge of the anti-theft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com