Elevator with floor heighting adjusting mechanism

A height adjustment mechanism and elevator technology, applied in the field of elevators, can solve problems such as the height of the elevator car, and achieve the effect of suppressing the height dimension, reducing the distance, and avoiding the increase of the space of the elevator passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

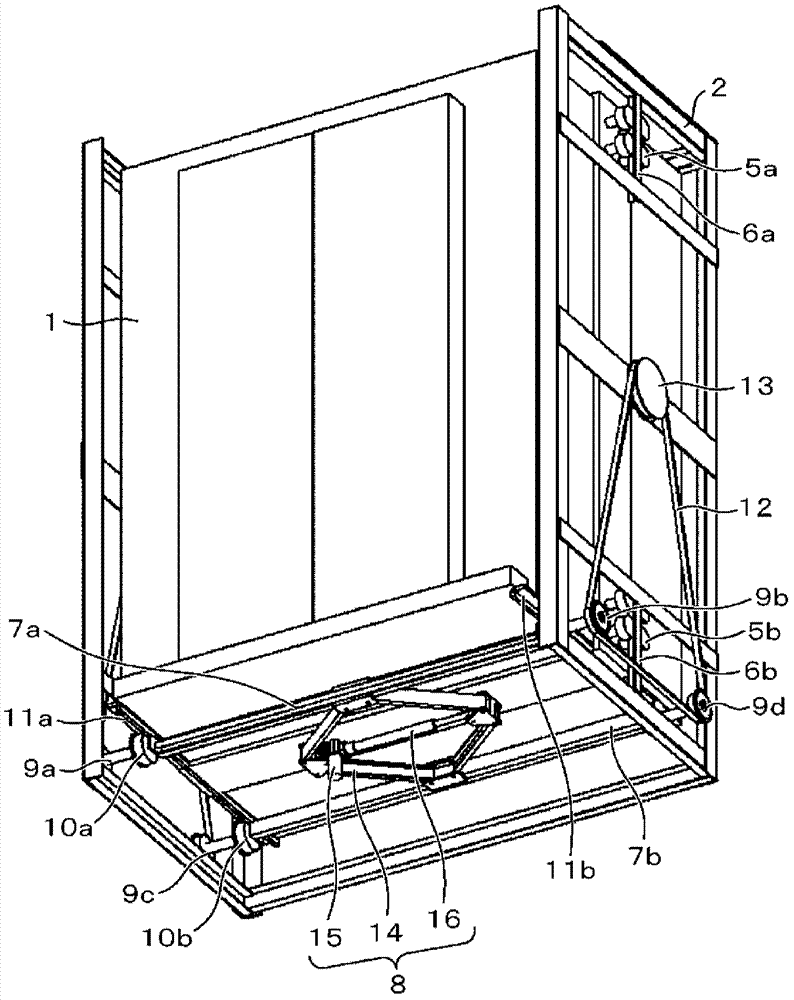

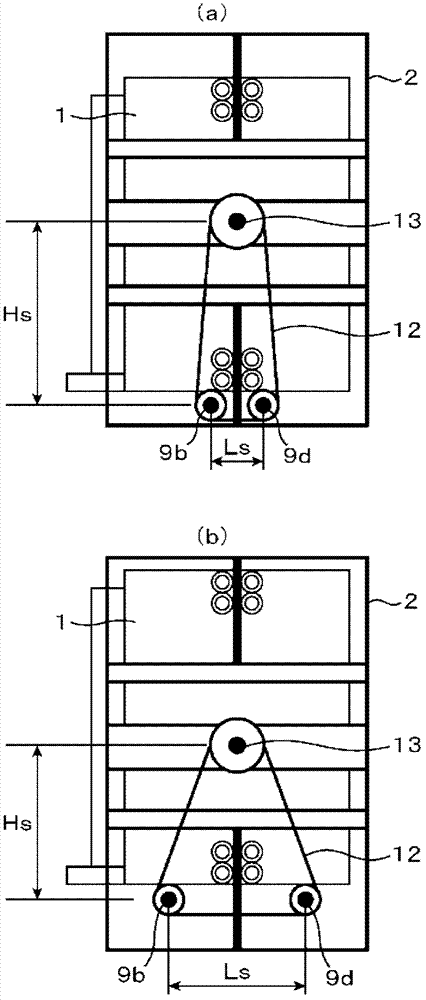

[0046] figure 1 is a perspective view of an elevator car. The elevator car of this embodiment is composed of an inner car 1 and an outer frame 2 . An unshown elevator door opening and closing motor and a control panel 4 for controlling power supply in the car, floor display, and elevator door opening and closing control are provided on the upper portion of the inner car 1 . The inner car 1 has inner car guide rollers 5a, 5b at the upper and lower portions of the left and right sides. The outer frame 2 has inner car guide rails 6a, 6b at the upper and lower portions of the left and right sides. The inner car 1 is arranged inside the outer frame 2, and the inner car guide rails 6a, 6b are capable of guiding the inner car guide rollers 5a, 5b in the lifting direction. Specifically, the inner car guide rollers 5a, 5b arranged on the inner car 1 and the inner car guide rails 6a, 6b arranged on the outer frame 2 can be configured to move up and down (in the lifting direction) rel...

no. 2 example

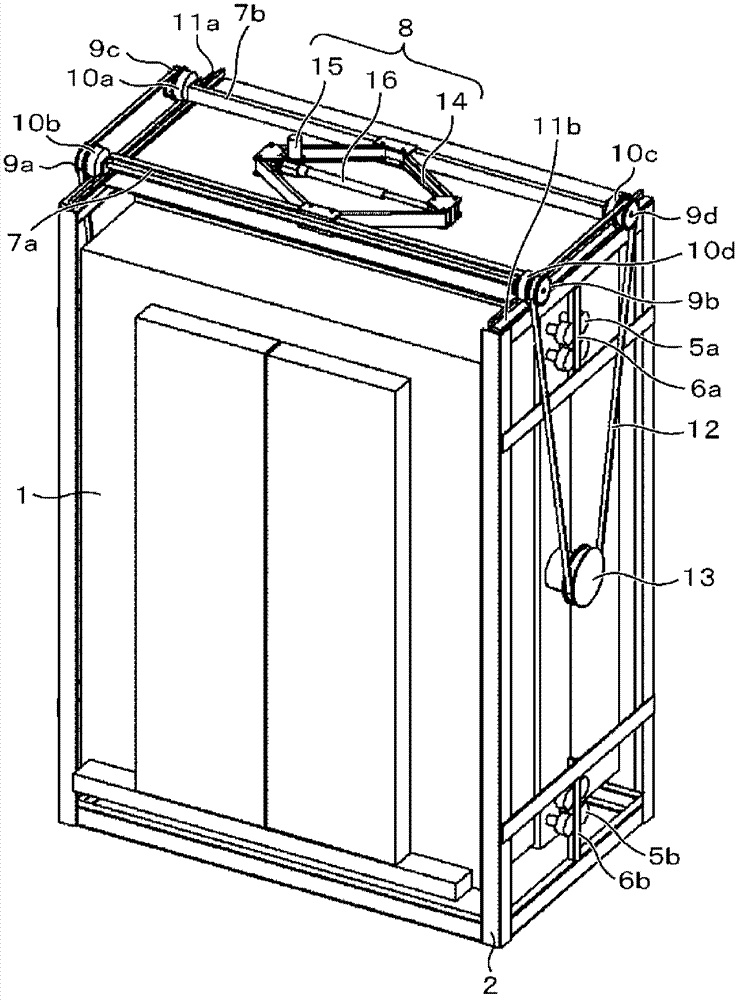

[0059] image 3 is a perspective view of an elevator car. The elevator car consists of an inner car 1 and an outer frame 2 . On the upper part of the inner car 1, a motor for opening and closing the elevator doors (not shown) is installed at a position where it will not interfere with the floor height adjustment mechanism, and controls the power supply control, floor display, and door opening and closing control in the car. Disk 4. The inner car 1 has inner car guide rollers 5a, 5b at the upper and lower portions of the left and right side surfaces. Inner car guide rails 6 are provided on the upper and lower portions of the left and right sides of the outer frame 2 . The inner car 1 is installed in the outer frame 2 so that the inner car guide rail 6 can guide the inner car guide rollers 5a, 5b in the lifting direction.

[0060] The upper part of the outer frame 2 is provided with a floor height adjustment mechanism. The floor height adjustment mechanism is made of crossb...

no. 3 example

[0071] Figure 5 It is a perspective view showing a multi-car elevator in which six elevator cars 18a to 20a and 18b to 20b circulate in the hoistway 17 . The elevator cars 18a to 20a are elevator cars with a floor height adjustment mechanism described in the first embodiment. It is also possible to use a non-illustrated elevator car with a floor height adjustment mechanism according to the second embodiment.

[0072] The floor height adjustment stroke of the floor height adjustment mechanism is set above the maximum deviation of the elevator car from the floor of the destination floor. A pair of elevator cars 18a, 18b are connected in a bucket shape by main ropes 21, 22, and are positioned so that when one of the elevator cars 18a reaches the uppermost floor, the other elevator car 18b reaches the lowermost floor. The main ropes 21, 22 are provided at the front and back of the elevator car 18a, and the elevator car 18a is fixed by two main rope fixing portions 23a, 24a inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com