Self-adaptive lubrication coating used in wide temperature ranges and preparing method thereof

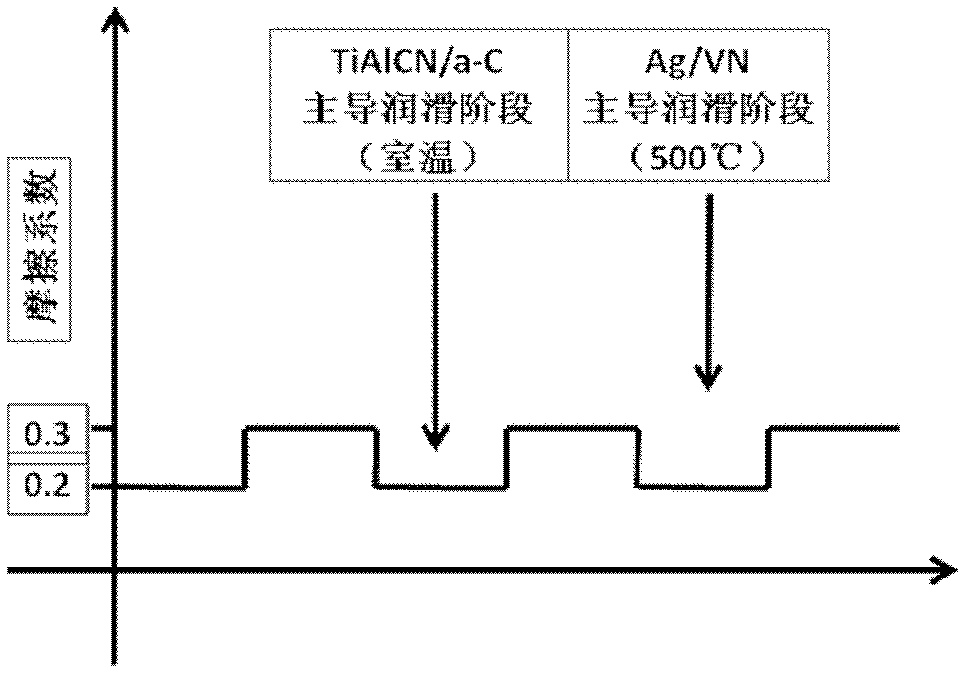

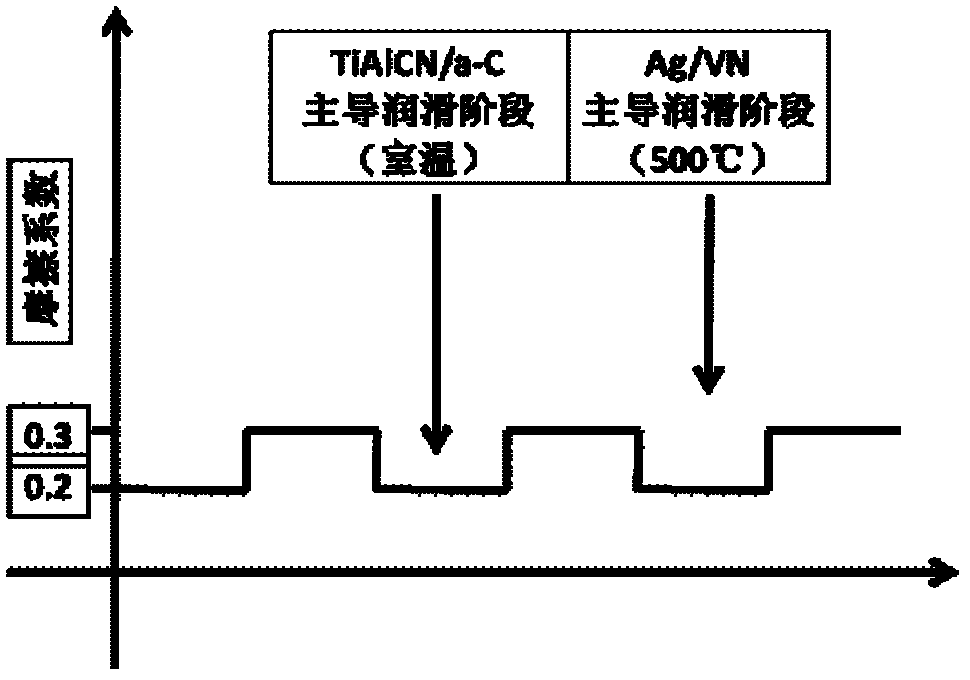

A lubricating coating, self-adaptive technology, applied to the surface of mechanical parts, can solve problems such as many lubricating phases, poor wear resistance, coating lubrication performance can not meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

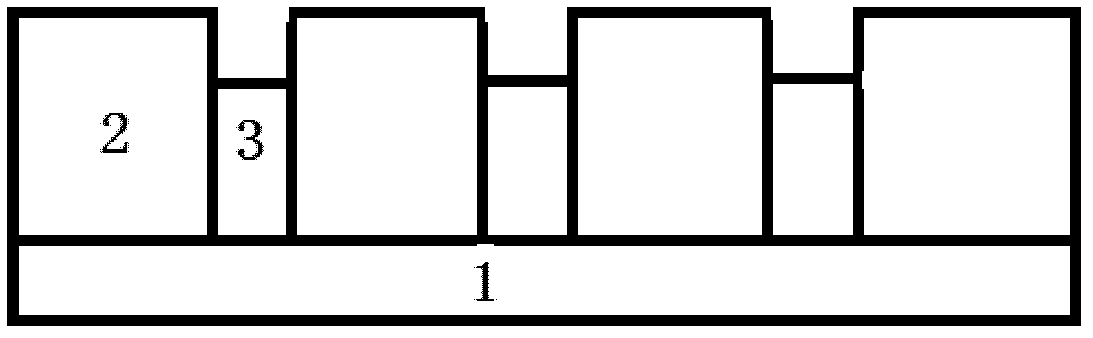

[0030] A wide temperature range adaptive lubricating coating for the surface of mechanical parts: the coating is composed of an intermediate layer on the substrate and an adaptive lubricating coating on the intermediate layer; the self-adapting lubricating coating The thickness is 0.5-200 microns. The self-adaptive lubricating coating is a nano-microstructure formed by interlacing the low-temperature lubricating unit coating and the high-temperature lubricating unit coating in a checkerboard shape. The low-temperature lubricating unit coating is TiAlCN phase / amorphous carbon phase composite, the high-temperature lubricating unit coating is Ag single phase / VN phase composite; the intermediate layer is Ti or Cr with a thickness of 50nm-200nm. In the TiAlCN phase, the atomic ratio of Ti and Al is 1:1.1, the percentage of C in TiAlCN is 16%, and the content of Ag in the Ag / VN composite phase is 30%.

[0031] The preparation method is as follows: the surface of the Si-based microme...

Embodiment 2

[0033]A wide temperature range adaptive lubricating coating for the surface of mechanical parts: the coating is composed of an intermediate layer on the substrate and an adaptive lubricating coating on the intermediate layer; the self-adapting lubricating coating The thickness is 0.5-200 microns. The self-adaptive lubricating coating is a nano-microstructure formed by interlacing the low-temperature lubricating unit coating and the high-temperature lubricating unit coating in a checkerboard shape. The low-temperature lubricating unit coating is TiAlCN phase / amorphous carbon phase composite, the high-temperature lubricating unit coating is Ag single phase / VN phase composite; the intermediate layer is Ti or Cr with a thickness of 50nm-200nm. In the TiAlCN phase, the atomic ratio of Ti and Al is 1:1, the percentage of C in TiAlCN is 26%, and the content of Ag in the Ag / VN composite phase is 40%. Si is added to the TiAlCN phase with a content of 0.5%.

[0034] First, clean the su...

Embodiment 3

[0036] A wide temperature range adaptive lubricating coating for the surface of mechanical parts: the coating is composed of an intermediate layer on the substrate and an adaptive lubricating coating on the intermediate layer; the self-adapting lubricating coating The thickness is 0.5-200 microns. The self-adaptive lubricating coating is a nano-microstructure formed by interlacing the low-temperature lubricating unit coating and the high-temperature lubricating unit coating in a checkerboard shape. The low-temperature lubricating unit coating is TiAlCN phase / amorphous carbon phase composite, the high-temperature lubricating unit coating is Ag single phase / VN phase composite; the intermediate layer is Ti or Cr with a thickness of 50nm-200nm. In the TiAlCN phase, the atomic ratio of Ti and Al is 1:1.1, the percentage content of C in TiAlCN is 16%, and the content of Ag in the Ag / VN composite phase is 5%-60% (this embodiment can be 30% and 40%). The TiAlCN phase adds Nb and Cr e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap