Slide bearing joint in well with adjustable wellhead

A sliding bearing and adjusting bearing technology, which is applied to sliding contact bearings, bearing components, shafts and bearings, etc., can solve the problems of reduced life of downhole tools, time-consuming and labor-intensive problems in bearing sections, and improve work efficiency and increase continuous working time. , the effect of reducing the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

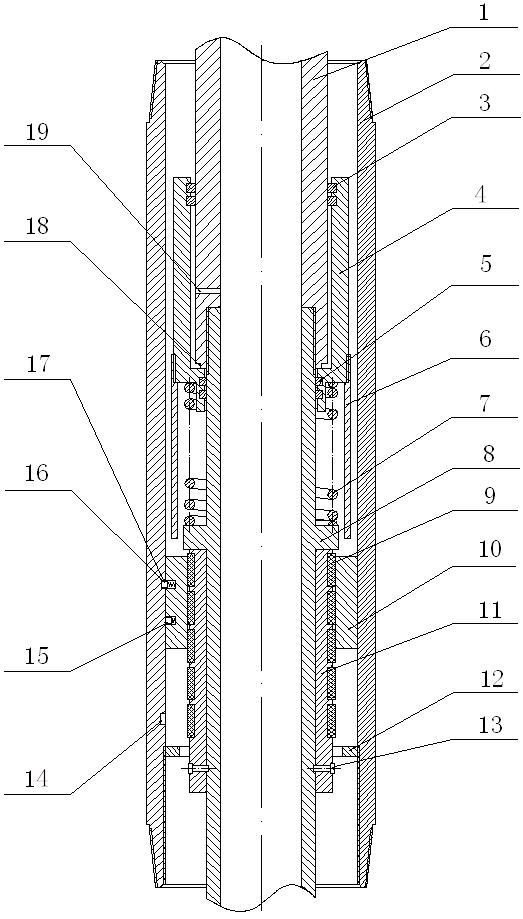

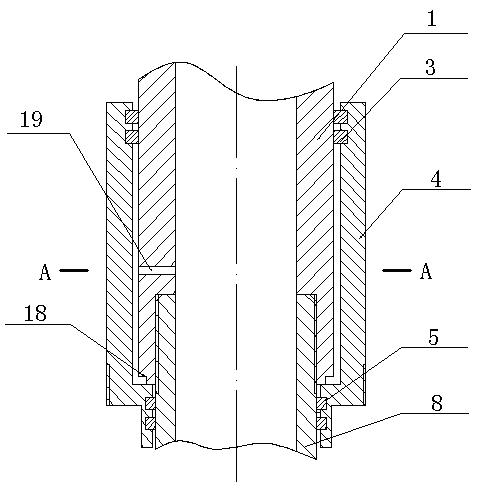

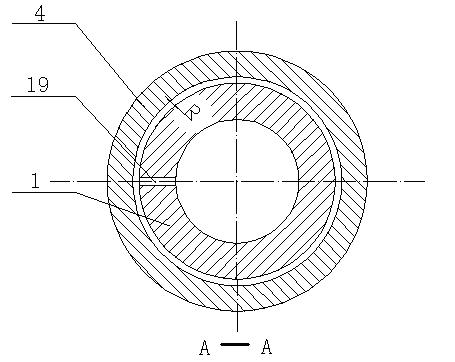

[0013] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a wellhead adjustable downhole sliding bearing section of the present invention is mainly composed of upper rotating shaft 1, shell 2, upper sealing ring 3, sliding sleeve 4, lower sealing ring 5, thrust sleeve 6, spring 7, and lower rotating shaft 8. Self-lubricating layer 9, sliding bearing outer ring 10, sliding bearing inner ring 11, positioning baffle 12, and locking screw 13. The upper rotating shaft 1 is a hollow shaft and the lower rotating shaft 8 is connected by threads; the lower part of the upper rotating shaft 1 is provided with a liquid guide hole 19, which guides the drilling fluid flowing through the upper rotating shaft 1 In the gap between the rotating shaft 1 and the sleeve 4; a boss 18 is provided at the lower end of the upper rotating shaft 1 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com