Air charging device of oxidation starting groove

An inflatable device and gas head technology, applied in container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve problems affecting the reaction in the tank, uneven gas supply, and affecting oxidation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

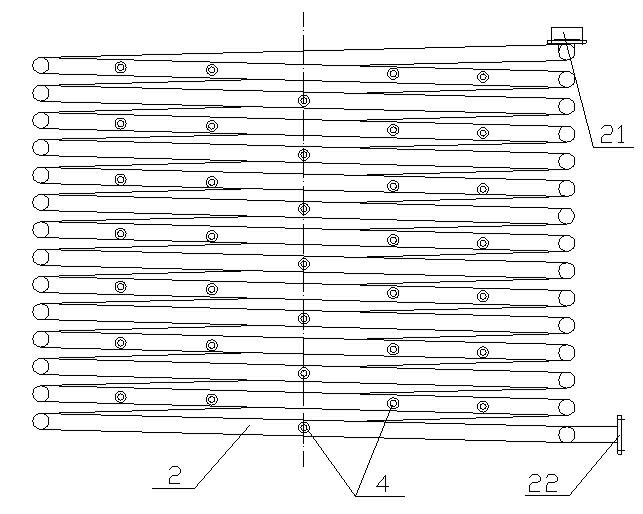

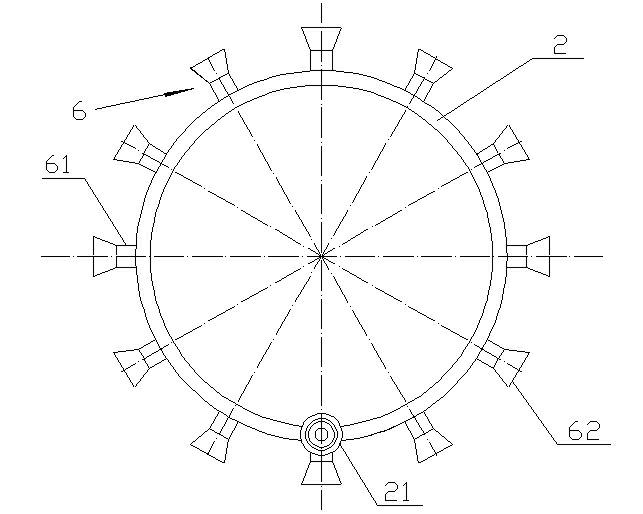

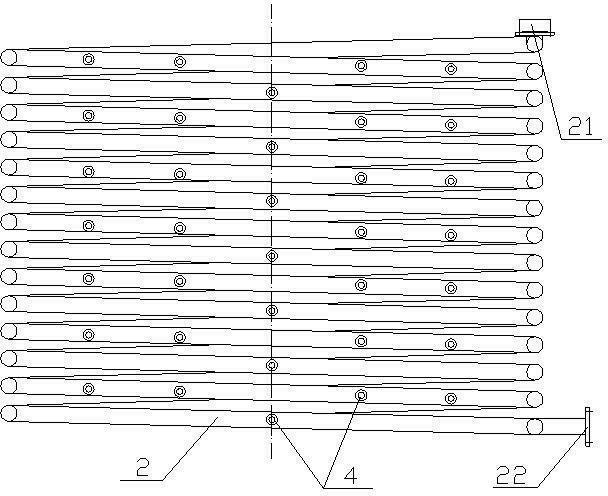

[0017] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0018] An embodiment of the present invention, a kind of oxidation start tank charging device, such as Figure 1-2 As shown, it includes a circular spiral air inlet pipe 2, and an air outlet 4 positioned on the wall of the air inlet pipe 2. The two ends of the air inlet pipe 2 are open, and one end is an air inlet end 21, which extends along the axis of the spiral body. It is connected with the air pump, and the other end is the air outlet end 22, which extends along the direction of the spiral tangent. The helical body of the intake pipe 2 rotates one circle in the circumferential direction to form a layer, and the intervals between each lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com