Gas-liquid separator with heat-returning function and application method thereof to air conditioning unit

A gas-liquid separator and air-conditioning unit technology, which is applied in the field of air-conditioning, can solve problems such as increased manufacturing costs, increased compressor power consumption, and increased compressor resistance, and achieves cost optimization, cost reduction, and cost realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

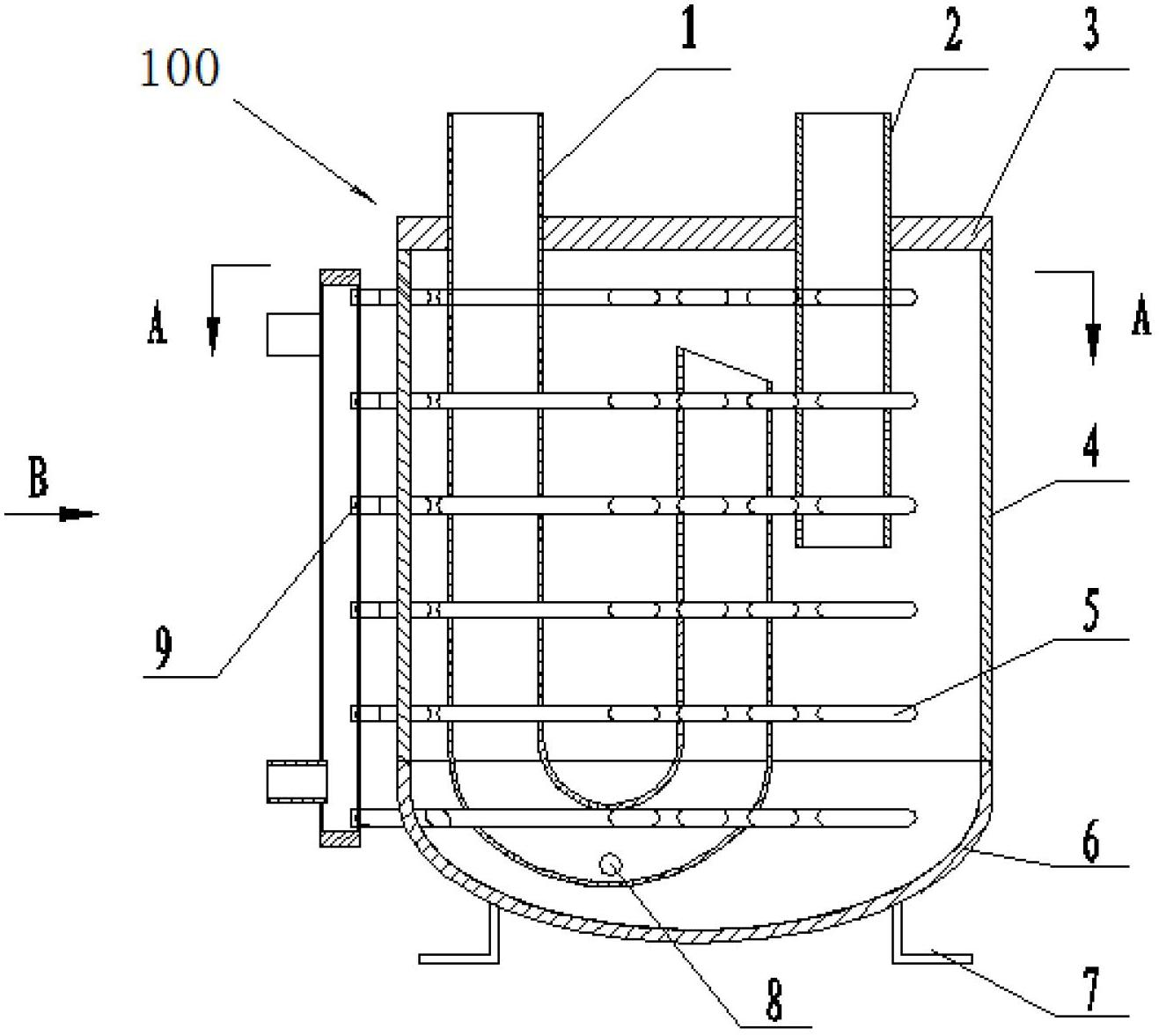

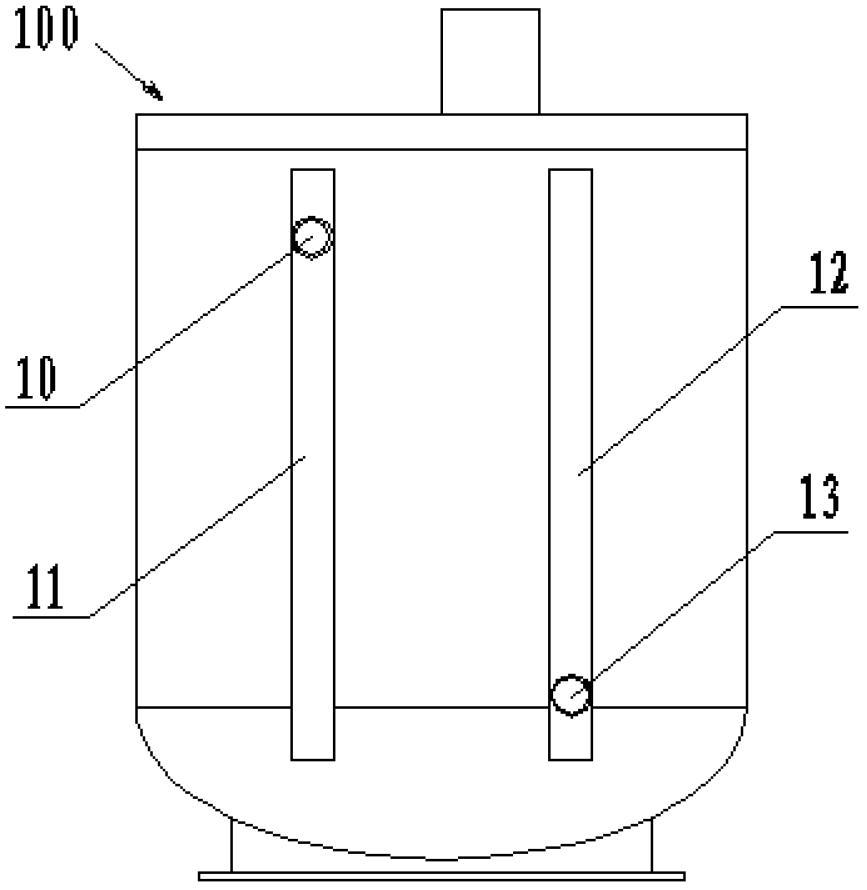

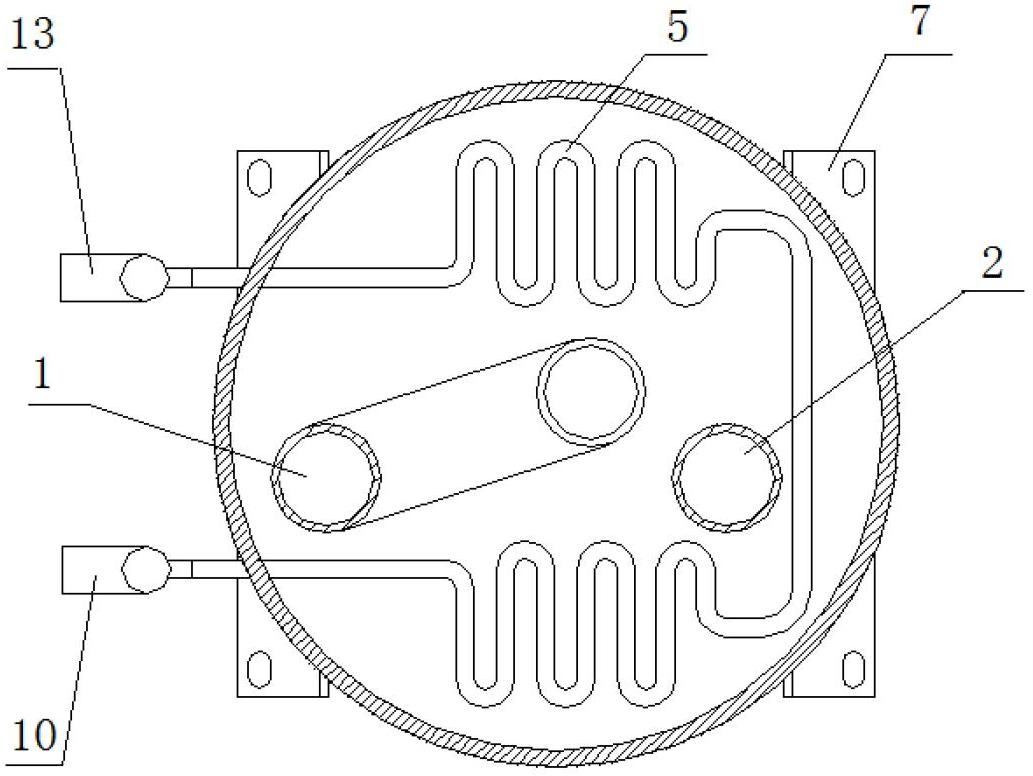

[0028] figure 1 , figure 2 and image 3 An embodiment of the gas-liquid separator with heat recovery function according to the present invention is shown. The gas-liquid separator 100 according to the present invention includes a superheating passage and a subcooling passage, and the superheating passage has an inlet pipe 2 for introducing refrigerant vapor into the gas-liquid separator 100 and an outlet pipe 1 for discharging refrigerant vapor out of the gas-liquid separator 100 The subcooling passage has one or more subcooling tubes 5 located in the gas-liquid separator 100 , and the refrigerant liquid flows through the subcooling tubes 5 and exchanges heat with the refrigerant vapor introduced into the gas-liquid separator 100 .

[0029] The subcooling passage also has a liquid uniform pipe 11, one end of the supercooled pipe 5 is connected to the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com