Condensing unit, liquid spraying control method and control device thereof and air conditioner

A technology of condensing unit and control method, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems that the liquid injection solenoid valve cannot control the injection amount, the compressor stops, and the compressor is damaged. Wide range of liquid volume control, improved reliability, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

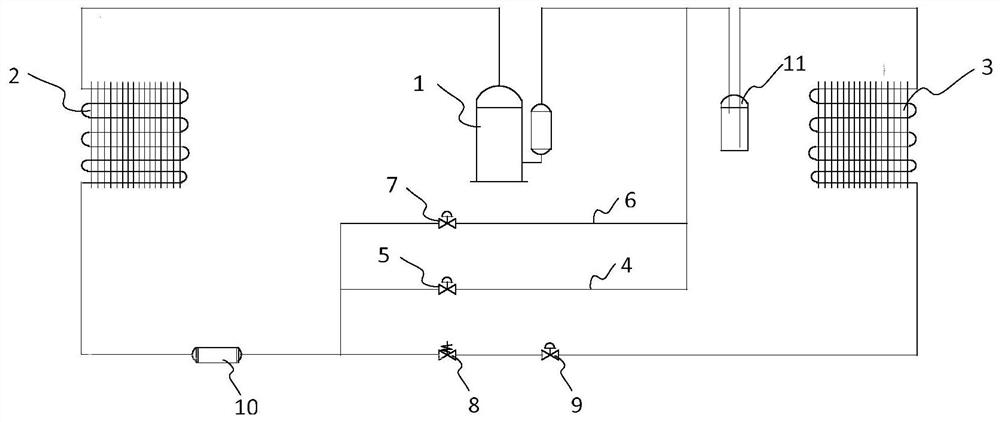

[0033] like figure 1 As shown, this embodiment provides a condensing unit, including: a compressor 1; a condenser 2; at least two liquid injection branches for cooling the compressor, and the at least two liquid injection branches are connected in parallel to the compressor Between the suction port of the compressor and the outlet of the condenser, each liquid injection branch is provided with at least one regulating valve, which is used to adjust the liquid injection amount for cooling the compressor.

[0034] The condensing unit of this embodiment includes a compressor 1, a condenser 2 and at least two liquid injection branches, and the at least two liquid injection branches are connected in parallel between the suction port of the compressor 1 and the outlet of the condenser 2, and each injection branch At least one regulating valve is arranged on the liquid branch. The condensing unit provided in this embodiment can adopt the control method of double-channel liquid sprayi...

Embodiment 2

[0036] In Embodiment 1, further, as figure 1 As shown, at least two liquid spraying branches include: a main liquid spraying branch 4, on which a first regulating valve 5 is arranged; an auxiliary liquid spraying branch 6, which is provided with a The second regulating valve 7 . Both the first regulating valve 5 and the second regulating valve 7 are electronic expansion valves.

[0037] The condensing unit provided in this embodiment includes a compressor 1, a condenser 2 and at least two liquid injection branches. The at least two liquid injection branches include a main liquid injection branch 4 and an auxiliary liquid injection branch 6. The main liquid injection branch A first regulating valve 5 is arranged on the channel 4, and a second regulating valve 7 is arranged on the auxiliary liquid injection branch 6. The first regulating valve 5 and the second regulating valve 7 are both used for regulating the amount of liquid spraying. Two regulating valves are used. Jointly...

Embodiment 3

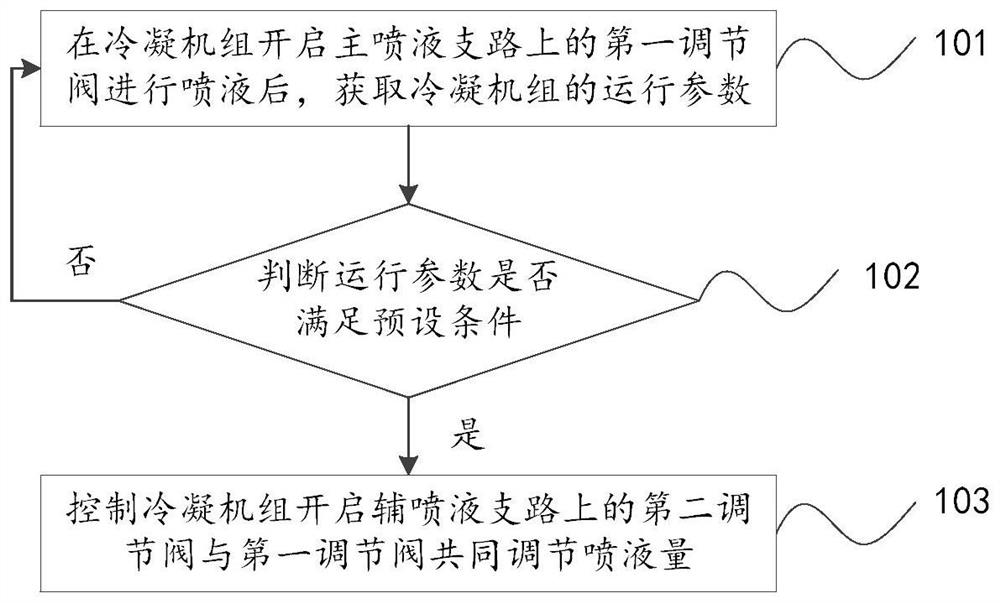

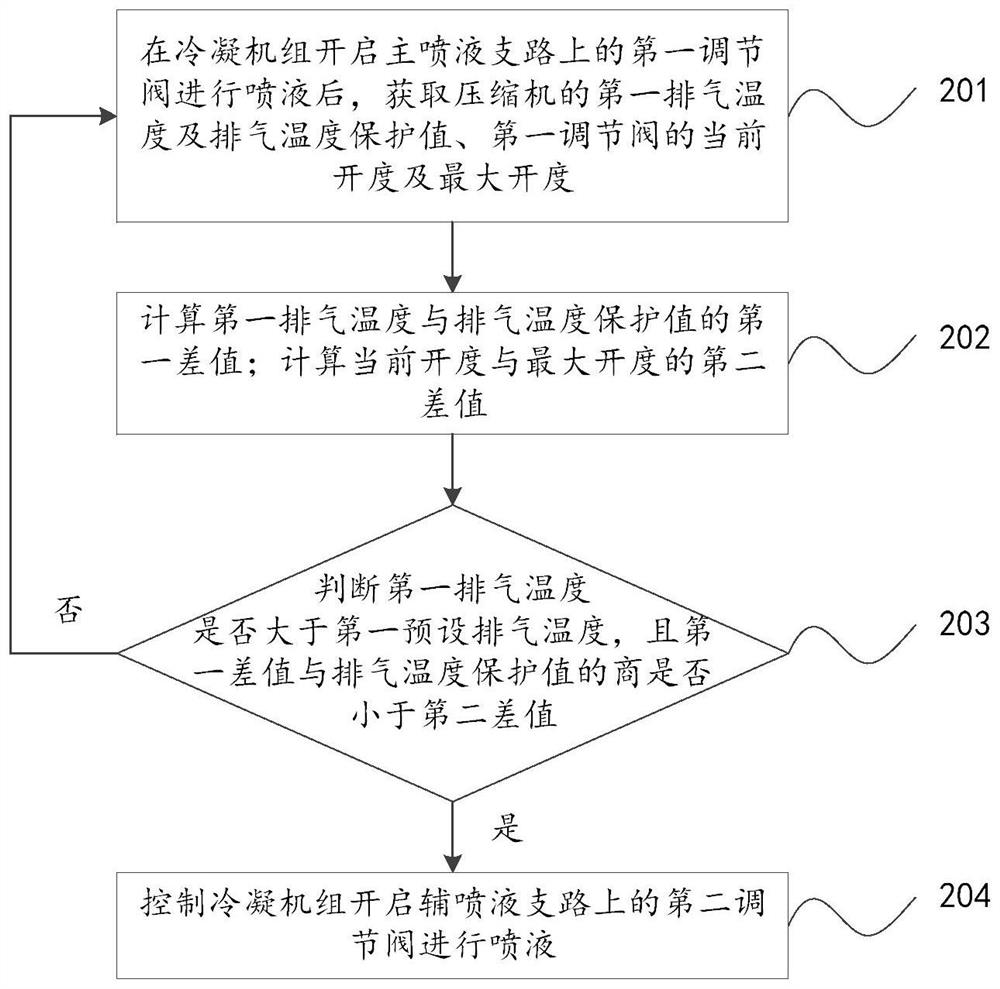

[0042] figure 2 A schematic flowchart of the liquid injection control method of the condensing unit of the present embodiment is shown. like figure 2 As shown, the control method includes:

[0043] Step 101, after the condensing unit opens the first regulating valve on the main liquid injection branch to spray liquid, obtain the operating parameters of the condensing unit;

[0044] Step 102, determine whether the operating parameters meet the preset conditions; if yes, go to Step 103; if not, return to Step 101;

[0045] Step 103: Control the condensing unit to open the second regulating valve on the auxiliary liquid injection branch to adjust the liquid injection amount together with the first regulating valve.

[0046] In the liquid injection control method of the condensing unit provided in this embodiment, after the condensing unit opens the first regulating valve on the main liquid injection branch for liquid injection, the operating parameters of the condensing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com