A device for removing siloxane from biomass gas

A biomass gas and siloxane technology, which is used in gas fuel, lighting and heating equipment, liquefaction, etc., can solve the problem of blocking heat exchange tubes, affecting system stability and safety, and high suction superheat of compressors, etc. problems, to avoid thermal shock and pressure shock, reduce ineffective working time, and extend the defrost cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

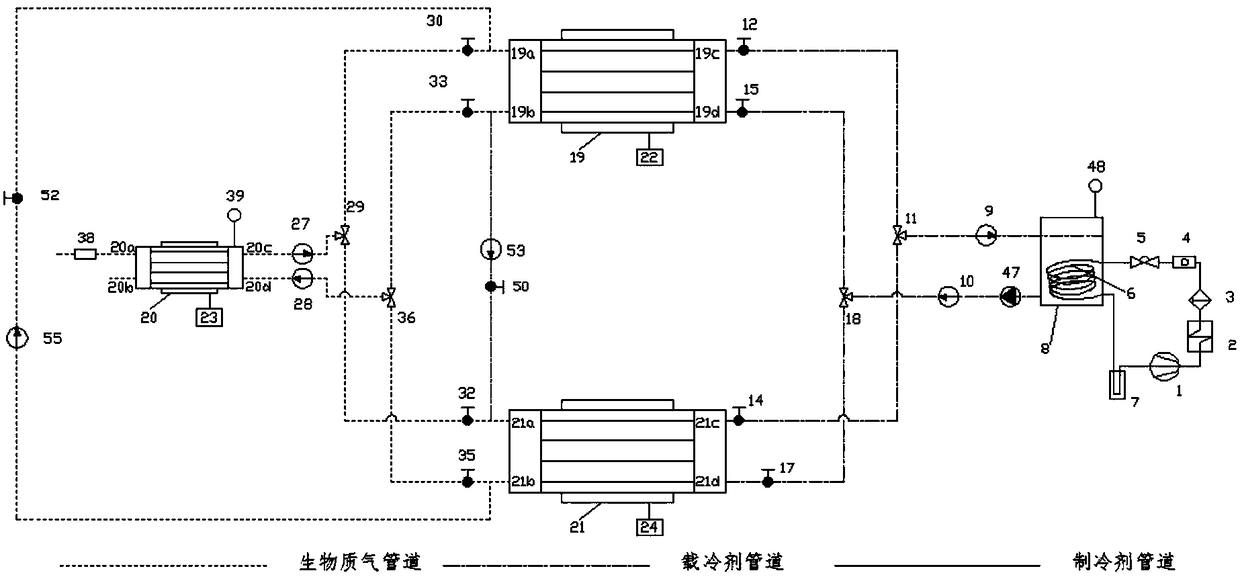

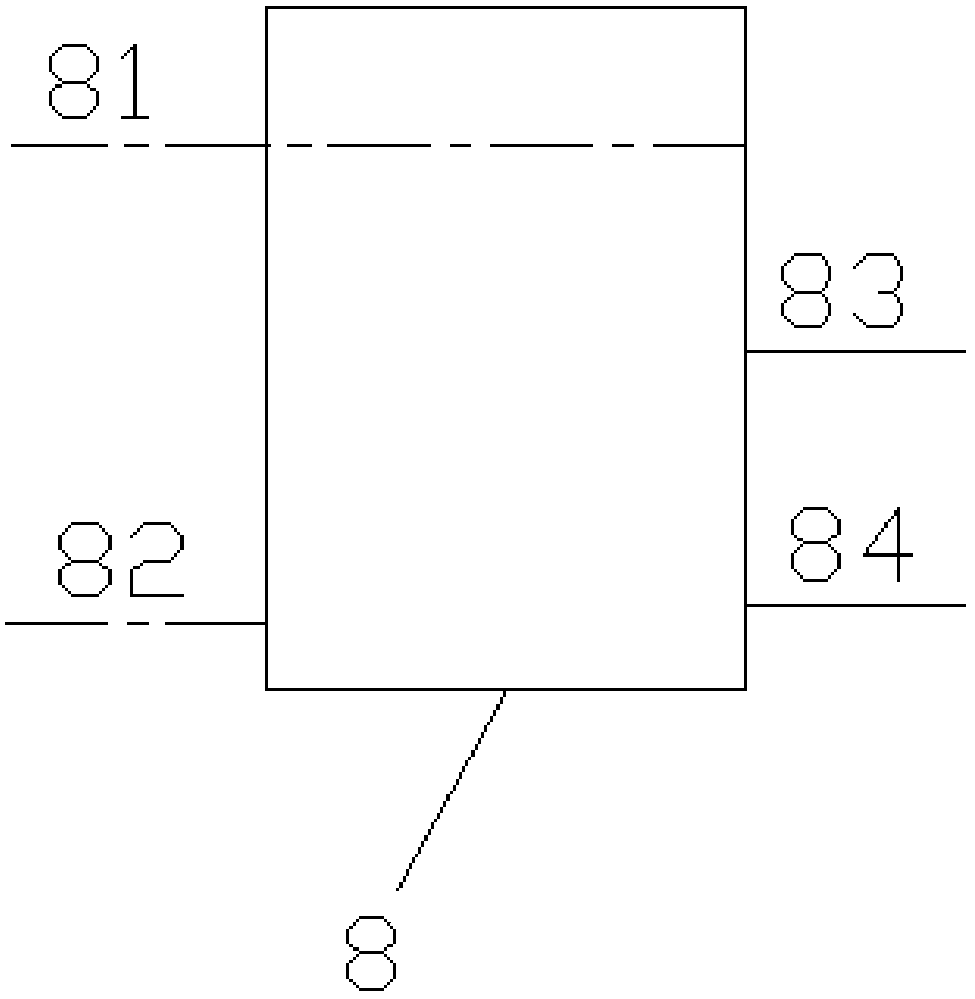

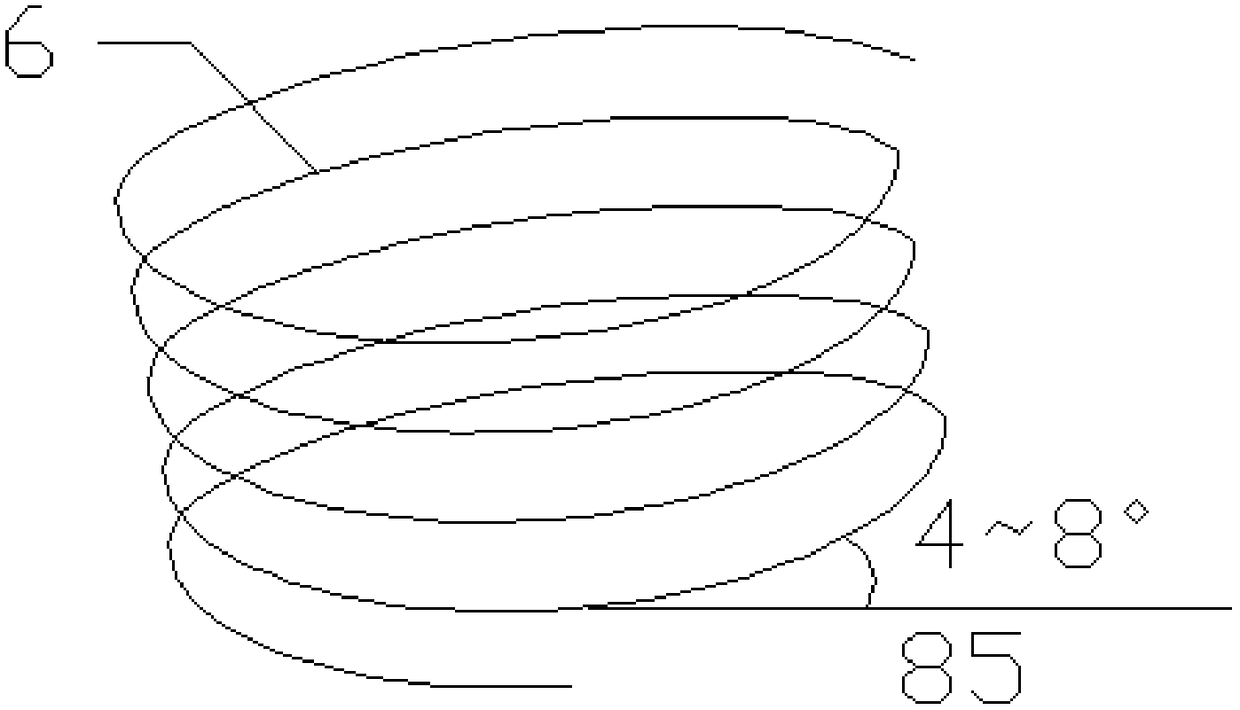

[0037] The cold storage device for removing siloxane in biomass gas of the present invention includes a refrigeration cycle unit, a refrigerant cycle unit and a biomass gas siloxane removal cycle unit. The present invention includes pipelines of three kinds of substances, which are respectively refrigerant pipelines, brine pipelines and biomass gas pipelines. The working principle is as follows: the refrigeration cycle unit is a simple refrigeration system, which releases cooling energy to the external refrigerant through the evaporating coil, and the refrigerant absorbs the cooling energy released by the evaporating coil and enters the silicon through the refrigerant circulation unit. The inflow gas of the oxane removal cycle unit is cooled and removed, and the first thing in the siloxane removal cycle unit is to pre-cool and homogenize the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com