Array base plate, preparation method of array base plate and liquid crystal display

An array substrate and a substrate technology, applied in the field of array substrates and their preparation, can solve the problems of poor Ion characteristics, slow charging speed, low brightness, etc., and achieve the effects of improving brightness, speeding up charging speed, and improving Ion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

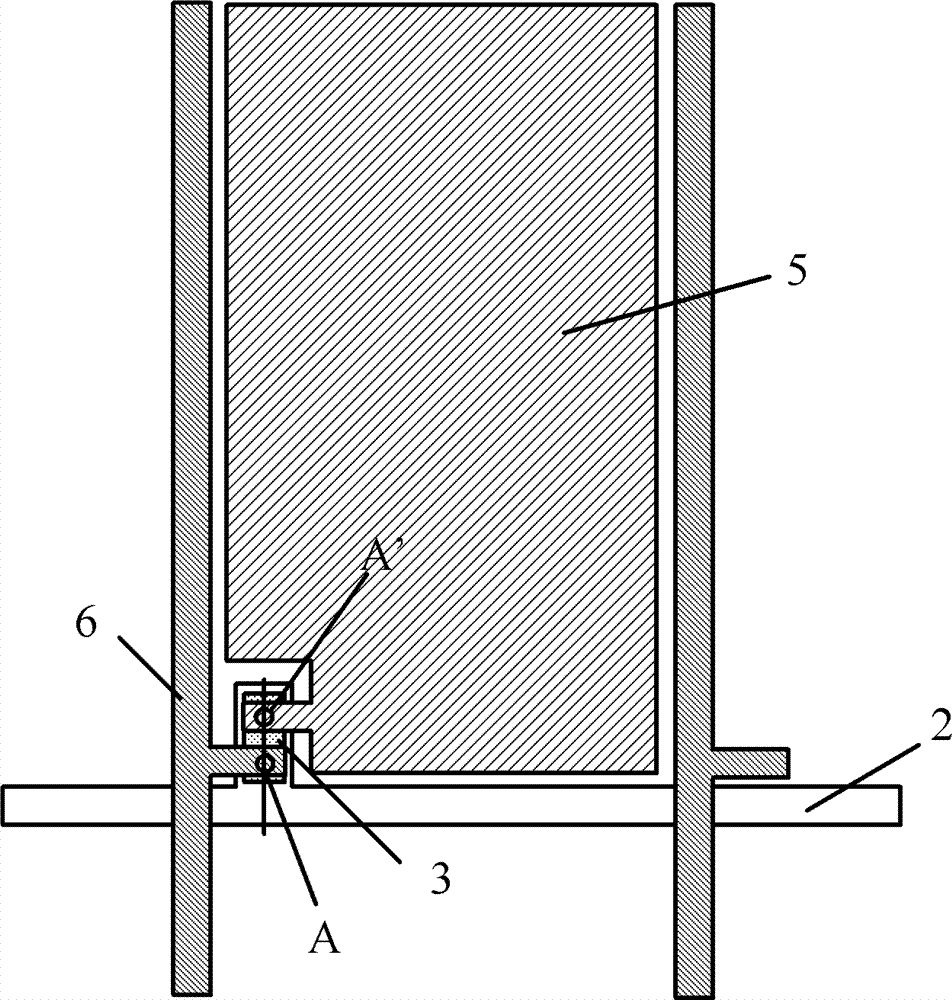

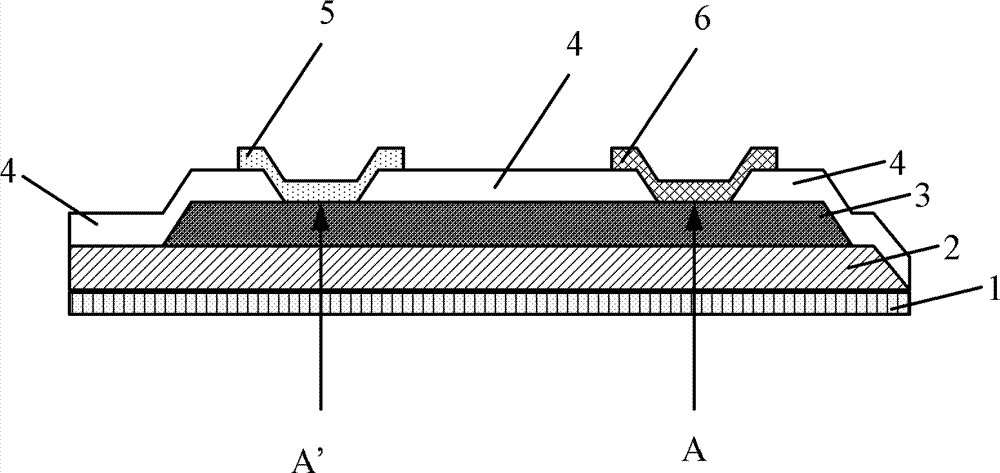

[0030] Embodiment 1 of the present invention provides an array substrate, and the structure diagram of the array substrate is as follows: figure 1 as shown, figure 1 A schematic structural diagram of a pixel region in the array substrate is specifically shown in . The array substrate for figure 1 A schematic cross-sectional view of a pixel region shown in figure 2 shown.

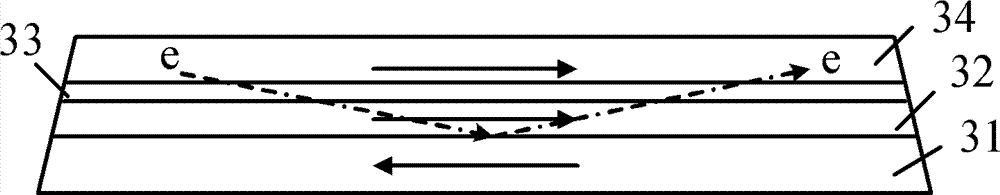

[0031] The array substrate includes a substrate 1, on which a control electrode layer 2, a giant magnetoresistance layer 3, an insulating layer 4, a pixel electrode layer 5 and a signal electrode layer 6 are sequentially deposited in a direction from close to the substrate 1 to away from the substrate 1, Wherein, the control electrode layer 2 , the giant magnetoresistance layer 3 and the insulating layer 4 together form a giant magnetoresistance active matrix.

[0032] For each pixel area, the insulating layer 4 is provided with two via holes, the signal electrode layer 6 is connected to the giant magne...

Embodiment 2

[0049] Embodiment 2 of the present invention provides a method for preparing an array substrate, such as Figure 4 Shown is the step flowchart of this method, and this method comprises:

[0050] Step 101, forming a control electrode layer.

[0051] This step includes: depositing a transparent conductive film on the substrate, forming a control electrode layer pattern on the transparent conductive film, and crystallizing the control electrode layer pattern, that is, crystallizing the control electrode layer pattern.

[0052] Preferably, the material of the transparent conductive film can be indium tin oxide ITO, and the transparent conductive film can be deposited by magnetron sputtering on the cleaned substrate, and formed on the transparent conductive film through the exposure etching process. Control the pattern of the electrode layer, and crystallize the pattern of the control electrode layer through an annealing process.

[0053] Step 102, forming a giant magnetoresistan...

Embodiment 3

[0069] Embodiment 3 of the present invention also provides a liquid crystal display including the array substrate provided in Embodiment 1 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com