Kettlebell and method of manufacturing the same

A technology for kettlebells and counterweights, applied in the direction of dumbbells, heavy objects, etc., can solve the problems of easy slipping, difficult processing, slipping handles or handles, etc., and achieve the effect of increasing the contact area, good sweat absorption effect, and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

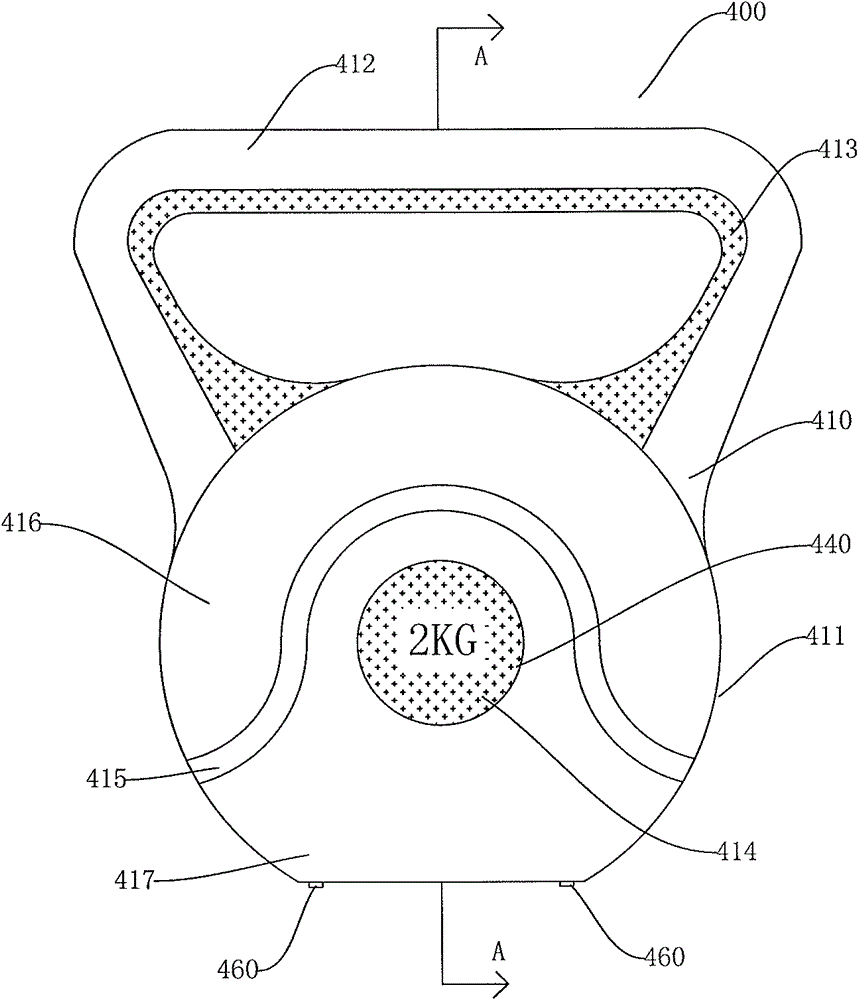

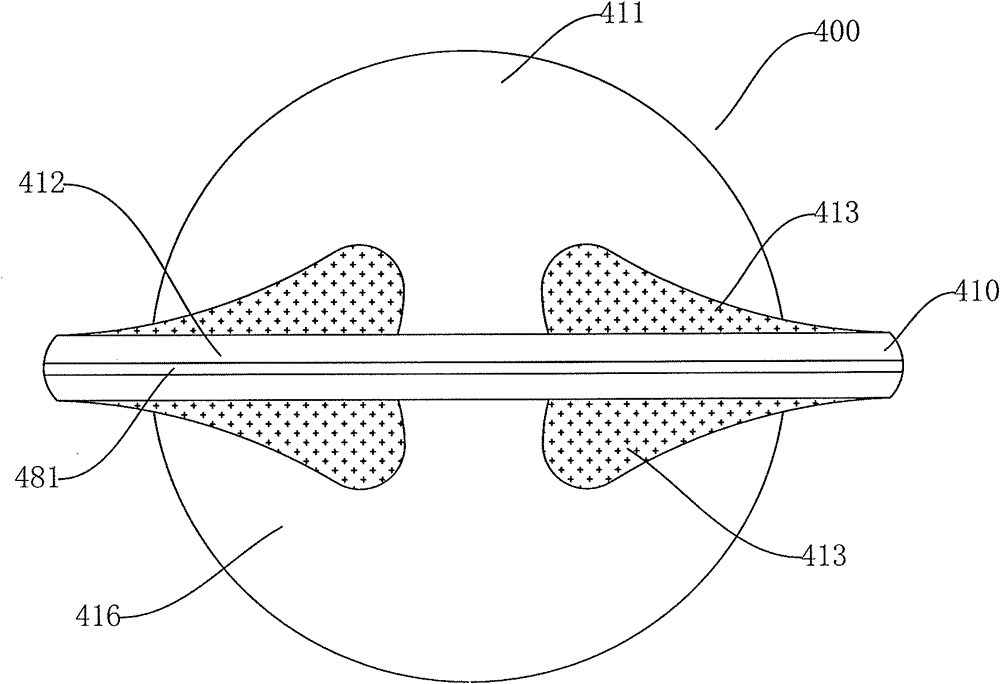

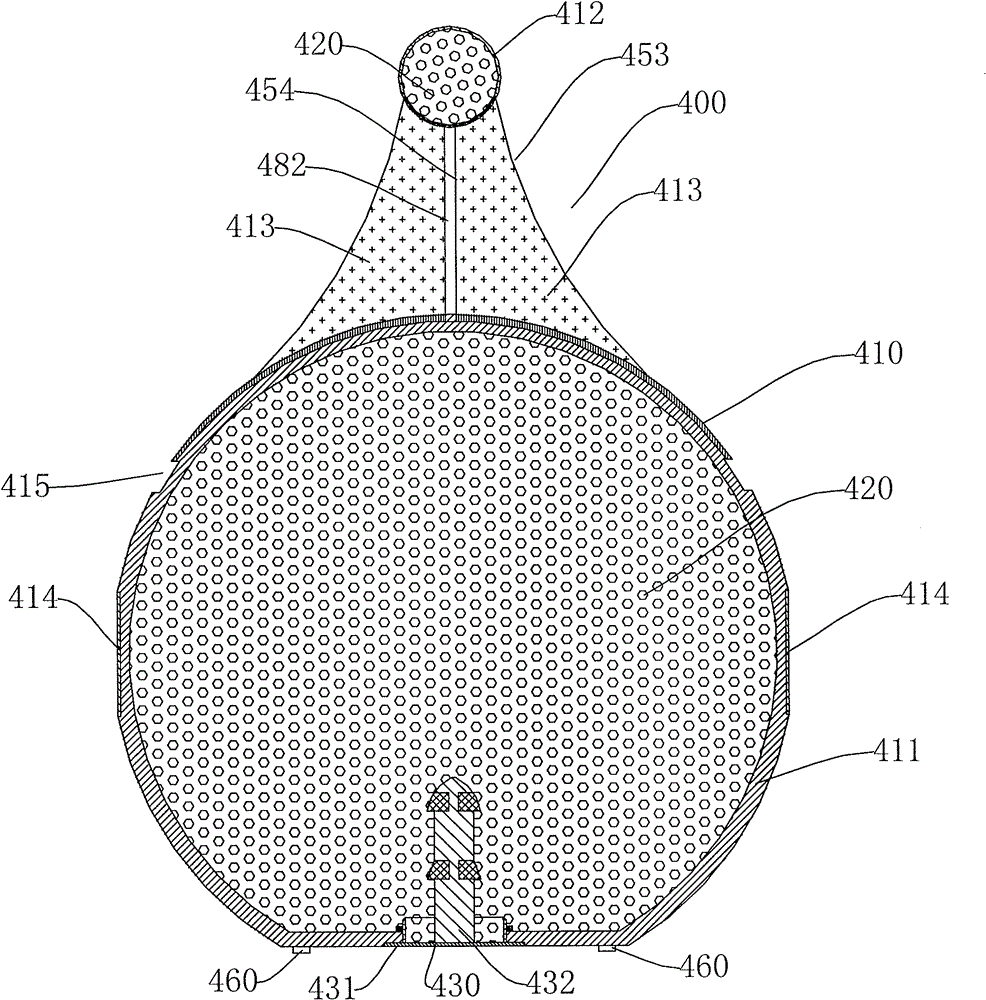

[0134] figure 1 Shown is a front view of a kettle dumbbell. figure 2 for figure 1 Top view of a kettle-style dumbbell. image 3 for figure 1 A-A section view. The dumbbell in this embodiment is symmetrical about the axis of the A-A section line. Such as figure 1 , figure 2 with image 3 As shown, the dumbbell 400 has a kettle shape. The front view and the rear view are symmetrical. The dumbbell 400 structure includes a shell 410 and a counterweight 420 filled in the shell. The housing 410 includes a dumbbell body housing 411 and a handle housing 412. The handle shell 412 is disposed above the dumbbell body shell 411, and its gripping part is cylindrical, and both ends are connected to the dumbbell body shell 411. The dumbbell body shell 411 and the handle shell 412 are integrally formed. The handle housing 412 is used for holding. The housing 410 is blow molded. During the blow molding process of the housing 410, an outer clamping line 481 and an inner clamping line 482...

Embodiment 2

[0143] Picture 11 This is the front view of the dumbbell in Example 2. Such as Picture 11 As shown, the dumbbell is composed of a shell and a weight filled in the shell. The dumbbell shell includes a handle shell 601 and two dumbbell head shells (602, 603). Two dumbbell head shells (602, 603) are respectively arranged at two ends of the handle shell 601. The handle housing 1 and the dumbbell head housings (602, 603) are an integral structure. The handle housing 601 is cylindrical. The grip portion of the handle housing 601 is provided with six piles 611 (three pieces are shown in the figure) evenly spaced along the circumferential direction. The thickness of the fleece 611 is 0.5 mm. The fleece 611 is arranged on the insert. The insert is arranged on the handle housing 601. An opening is provided at the end of the dumbbell head 603, and the counterweight is filled into the cavity of the housing through the opening. After filling, use the lid 430 to seal the opening.

[...

Embodiment 3

[0148] Figure 14 Shown is a schematic diagram of the lid structure in Example 3. Figure 15 It is a cross-sectional view of the cover A-A in Example 3. Such as Figure 14 , 15 As shown, the cover 430 includes a circular bottom plate 431. The thickness of the bottom plate 431 is the same as the height of the step 419. A cylinder wall 434 is provided on the bottom plate 431. The cylinder wall 434 is arranged in a circle around the pillar 432. The bottom plate 431 and the cylinder wall 434 form a cylinder. The cross-sectional area enclosed by the cylinder wall 434 is smaller than the cross-sectional area of the bottom plate 431. The upper end of the cylinder wall 434 has an inclined surface 4341. The outer peripheral surface of the cylinder wall 434 is provided with a flange 435 protruding from the cylinder wall 434. The side wall 4351 of the flange 435 is arc-shaped. The flange 435 is separated from the bottom plate 431 by a set distance, and a slot 436 is formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com