Automatic-cleaning shot blasting machine of inner wall of large tower tube

An automatic cleaning and shot blasting machine technology, which is applied in the direction of abrasive jet machine tools, grinding/polishing equipment, used abrasive processing devices, etc., can solve the problem of large waste of resources, susceptibility to pneumoconiosis, and low production efficiency, etc. problems, to achieve reasonable structure, improve working environment, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

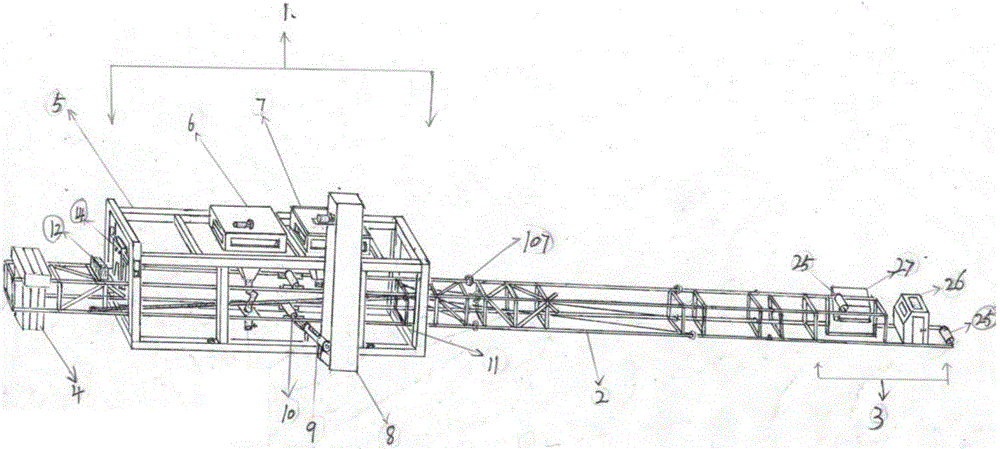

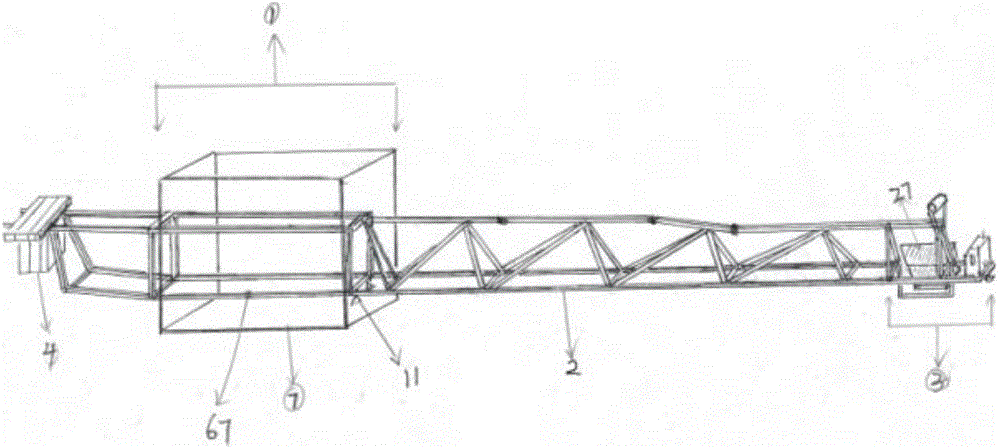

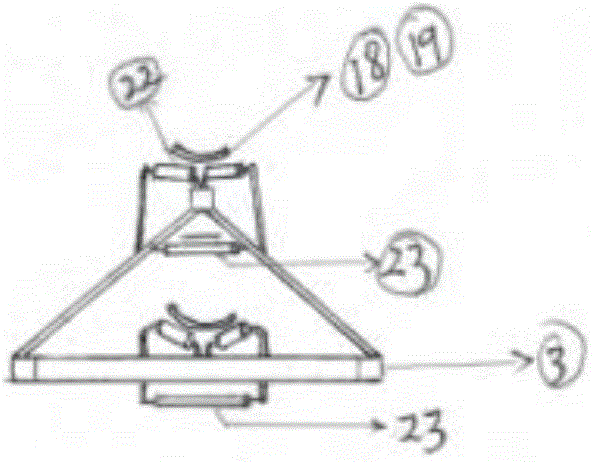

[0054] An automatic shot blasting machine for the inner wall of a large tower such as a wind power tower, its embodiment is composed of a support part 1, a balance arm 2, a throwing head part 3, and a counterweight part 4 ( figure 1 ).

[0055] Support part 1 ( figure 1 , 3 ), which consists of a square frame support mechanism 5, a dust removal system 6, a sand material box 7, a bucket elevator system 8, and a screw conveyor system 9.

[0056] The balance arm 2 can adopt a square frame type balance arm and an isosceles triangle frame type balance arm, both of which include a conveyor belt roller power machine system 10, and the conveyor belt pulley power machine system 10 is located in the balance arm below the sand 7, and the fulcrum 11 is located on the beam 34 in the front, middle and lower part of the support, the hydraulic station 12 is located on the balance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com