Method for producing oxalate through catalytic coupling reaction of carbon monoxide

A technology of gas catalysis and coupling reaction, applied in the direction of carbon monoxide or formate reaction preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the difficulty of temperature control, oxalate selection Low performance and other problems, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

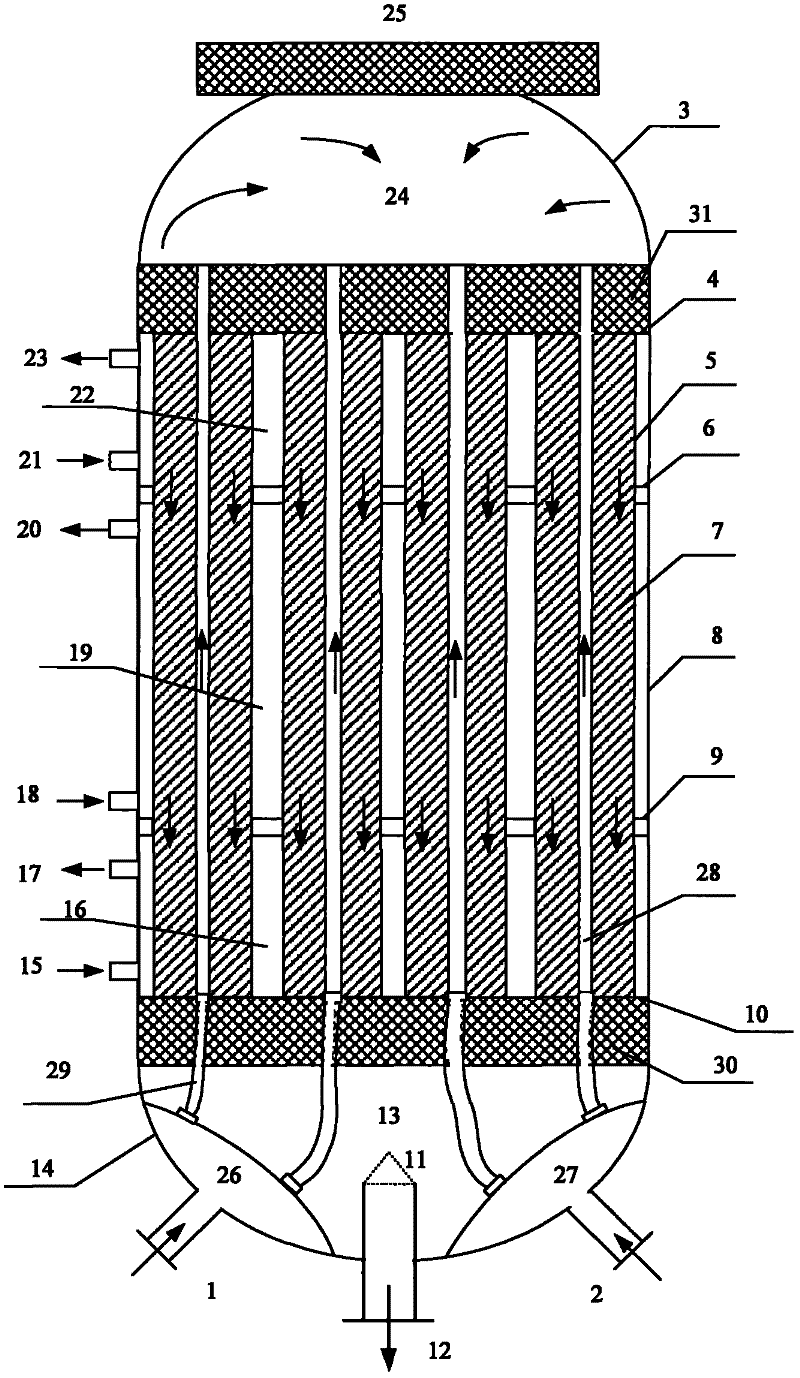

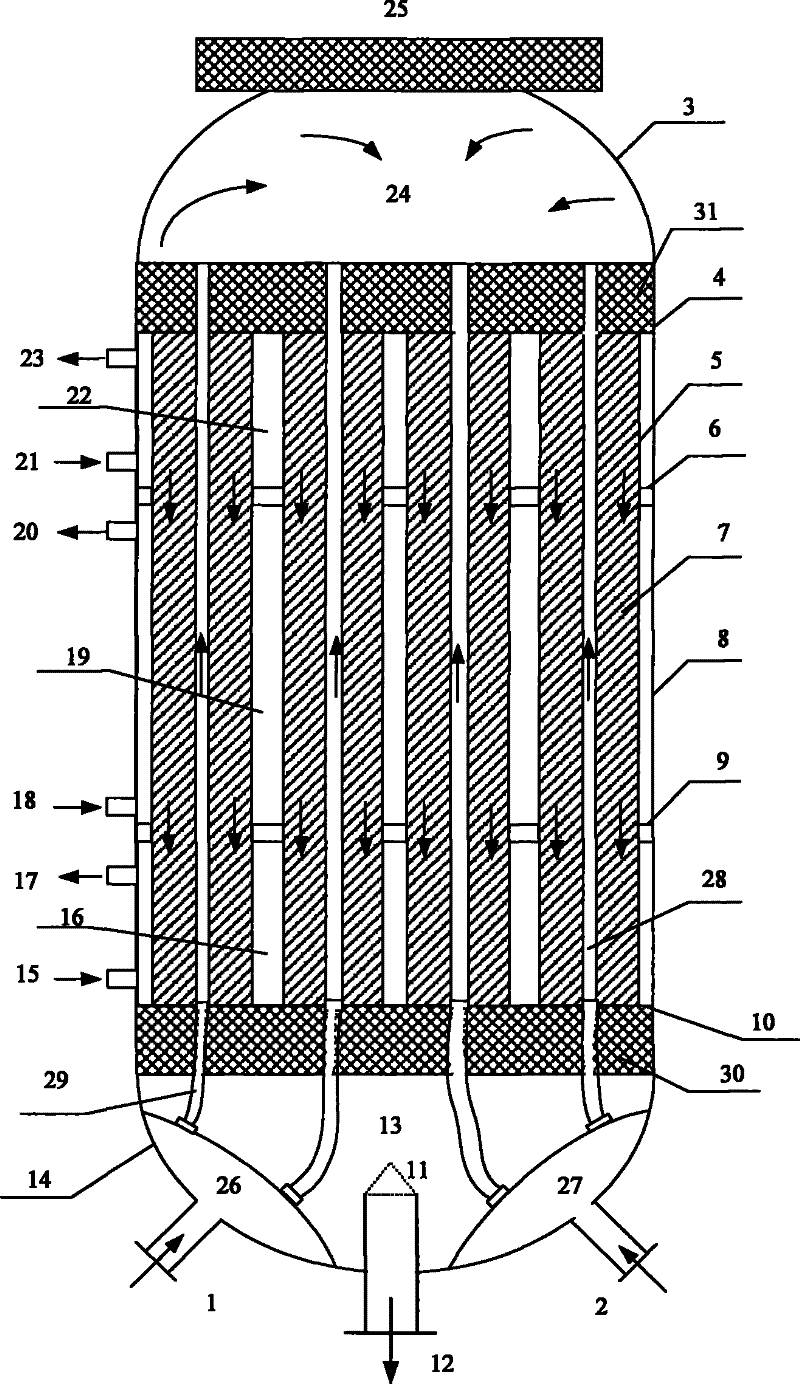

[0021] use figure 1 The reactor shown in the figure is a composite reactor with a sleeve structure of the inner tube and the outer tube and a hot spot distribution area to enhance heat transfer. The first, second and third heat exchange mediums all use saturated steam, but the pressure is different. , realize the temperature difference, so as to realize the control of the catalyst bed temperature of the reactor, the length of the first partition partition of the reactor from the reactor cover plate is 1 / 5 of the reactor length; The length under the partition is 1 / 6 of the reactor length. The height of the lower adiabatic catalyst layer of the reactor is 1 / 6 of the height of the isothermal catalyst bed; the height of the upper adiabatic catalyst layer is 1 / 10 of the height of the isothermal catalyst bed, and the palladium content is 0.5% palladium supported alumina catalyst as the catalyst , the molar ratio of CO and methyl nitrite is a mixed gas of 1.2:1 as a raw material, th...

Embodiment 2

[0023] use figure 1 The reactor shown in the figure is a composite reactor with a sleeve structure of the inner tube and the outer tube and a hot spot distribution area to enhance heat transfer. The first, second and third heat exchange mediums all use saturated steam, but the pressure is different. , to realize the temperature difference, so as to realize the control of the catalyst bed temperature of the reactor, the distance between the first partition partition of the reactor and the reactor cover is 1 / 8 of the length of the reactor; the distance between the second partition partition and the first partition The length under the partition is 1 / 5 of the reactor length. The height of the lower adiabatic catalyst layer of the reactor is 1 / 15 of the height of the isothermal catalyst bed; the height of the upper adiabatic catalyst layer is 1 / 15 of the height of the isothermal catalyst bed, and the palladium content is 0.2% palladium-loaded alumina catalyst as the catalyst , us...

Embodiment 3

[0025] use figure 1 The reactor shown in the figure is a composite reactor with a sleeve structure of the inner tube and the outer tube and a hot spot distribution area to enhance heat transfer. The first, second and third heat exchange mediums all use saturated steam, but the pressure is different. , to realize the difference in temperature, so as to realize the control of the catalyst bed temperature in the reactor. The length under the partition is 1 / 3 of the reactor length. The height of the lower adiabatic catalyst layer of the reactor is 1 / 8 of the height of the isothermal catalyst bed; the height of the upper adiabatic catalyst layer is 1 / 6 of the height of the isothermal catalyst bed, and the palladium content is 0.2% palladium-loaded alumina catalyst as the catalyst , the molar ratio of CO and methyl nitrite is a mixed gas of 1.3:1 as a raw material, the reaction temperature is 150 ° C, and the reaction volume space velocity is 5000 hours -1 , under the condition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com