Method for contacting lighting device, tool for performing the method and connection element for attachment on lighting device

A technology for lighting devices and connecting components, which is applied to the components of lighting devices, lighting devices, independent lighting devices, etc., can solve the problems of cost and flexibility, and achieve the effects of compact shape, improved sealing degree, and simplified contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

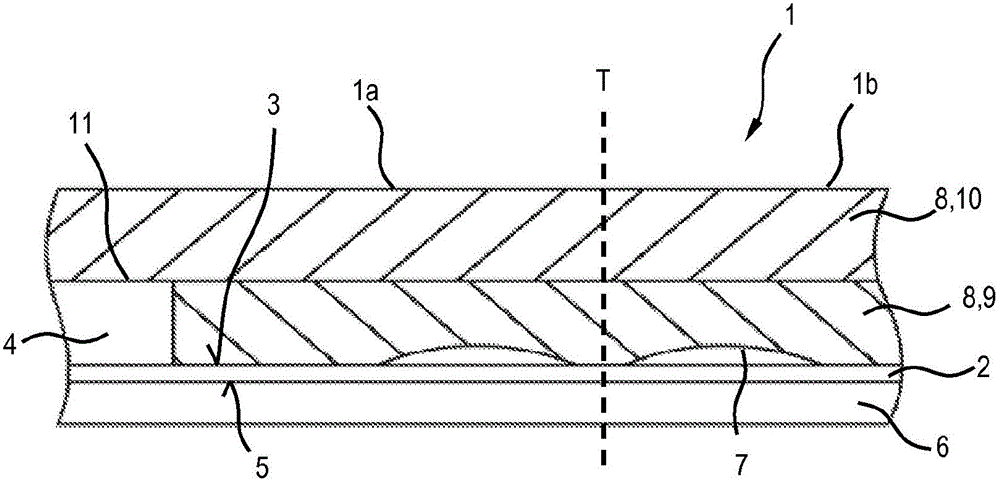

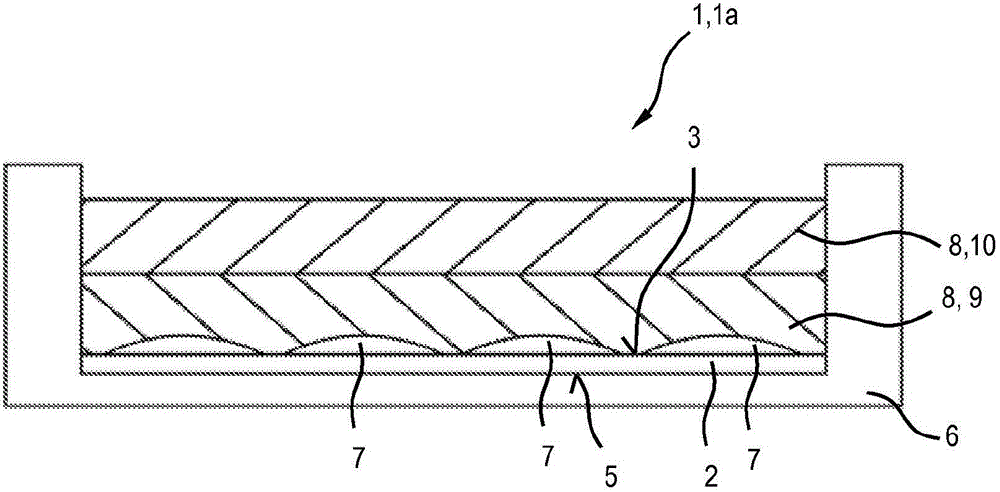

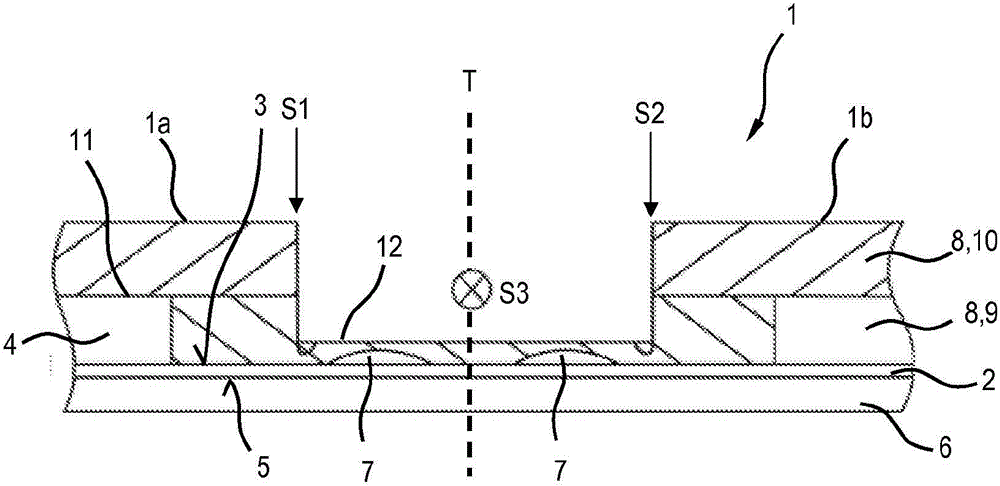

[0045] figure 1 A section through the lighting strip 1 according to the invention is shown in side view as a section. figure 2 The lighting strip 1 is shown in front view as a section.

[0046] refer to figure 1 and figure 2 , the lighting device in the form of a lighting strip 1 has a strip-shaped, flexible printed circuit board 2 , the upper or front side 3 of which is equipped with light-emitting diodes 4 arranged in rows. The rear side 5 of the circuit board 2 is fixed on the bottom of an elongated, U-shaped profile 6 in cross section (see figure 2 ). The profile 6 can have silicone as base material in order to be able to at least partially preserve the flexibility of the lighting strip 1 . The profile 6 can in particular be produced from an opaque material. The light-emitting diodes 4 radiate upwards from the open side of the profile 6 , wherein the profile 6 rises above the mounted printed circuit board 2 , 4 .

[0047]On the front side 3 of the circuit board 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com