Front structure of vehicle

A front structure and vehicle technology, applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., can solve problems such as difficult to ensure parting accuracy, difficult to ensure accuracy, and reduced sealing performance of headlights, so as to reduce layer difference The dispersion, type accuracy improvement, and the effect of reducing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

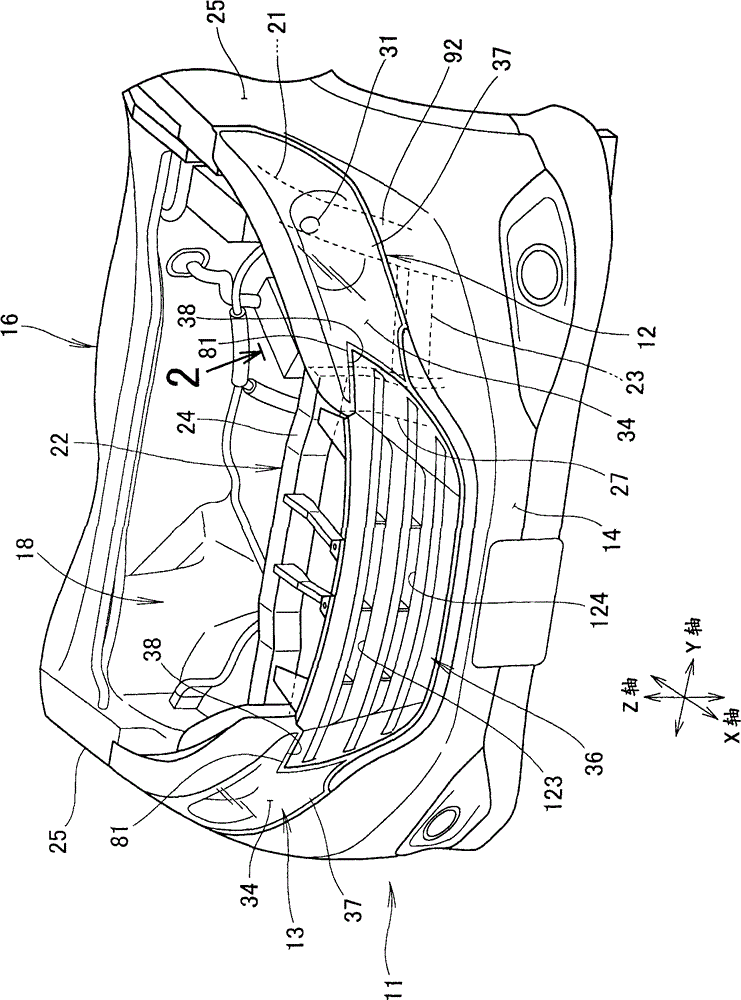

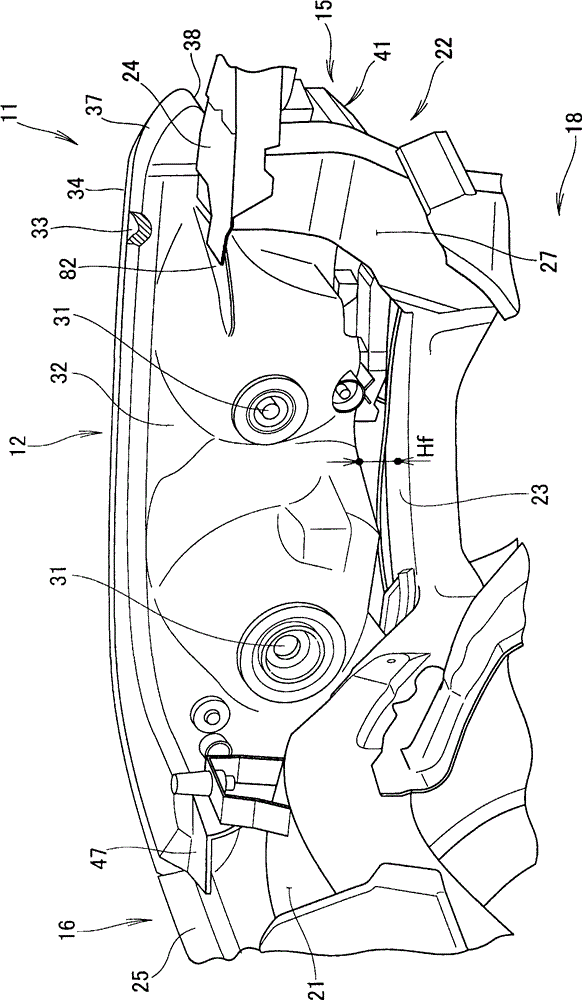

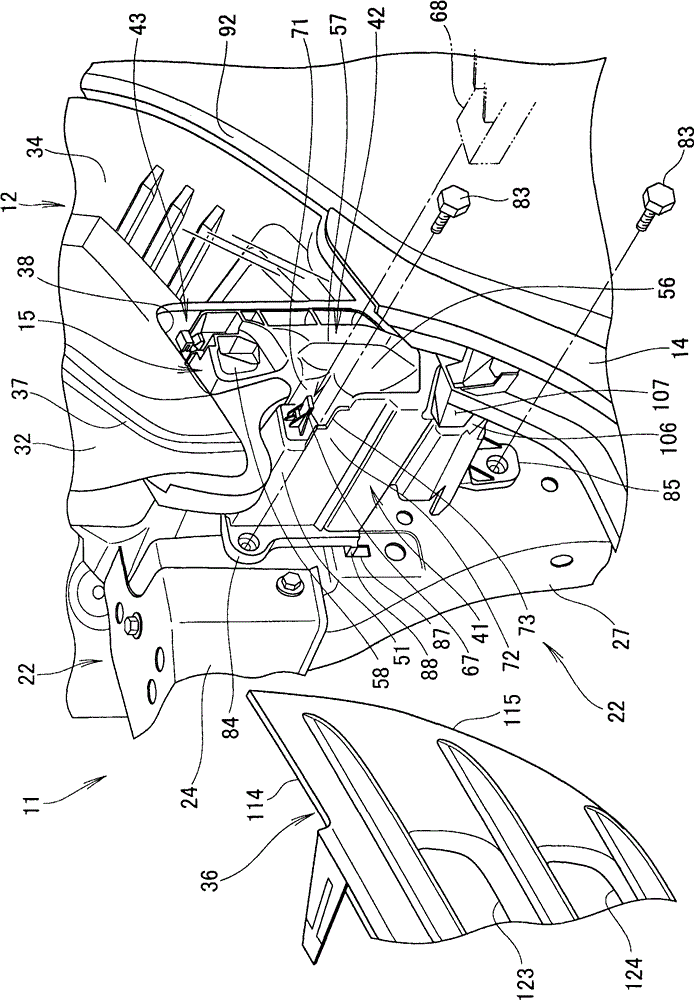

[0055] The vehicle front structure 11 of embodiment, as figure 1 , figure 2 As shown, a lamp fixing member 15 is used for fixing the headlights 12 and 13 and the front bumper exterior member 14 . The lamp fixing member 15 is mounted on a vehicle body 16 .

[0056] Body 16 has a front body 18 .

[0057] Here, front, rear, left, and right are defined from the perspective of the driver, and the vehicle front and rear direction is the X-axis direction, the vehicle width direction (vehicle left-right direction) is the Y-axis direction, and the vehicle up-down direction is the Z-axis direction.

[0058] The front body 18 has an upper member 21 , a bulkhead 22 , a bulkhead side frame 23 , a bulkhead rack 24 , and a front fender 25 .

[0059] One end of the partition side frame 23 is joined to the lower portion of the upper member 21 and the other end is joined to the partition vertical frame 27 of the partition panel 22 , and the partition side frame 23 is arranged substantially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com