Method for preparing catechol from lignin

A catechol, lignin technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as low selectivity and non-renewable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

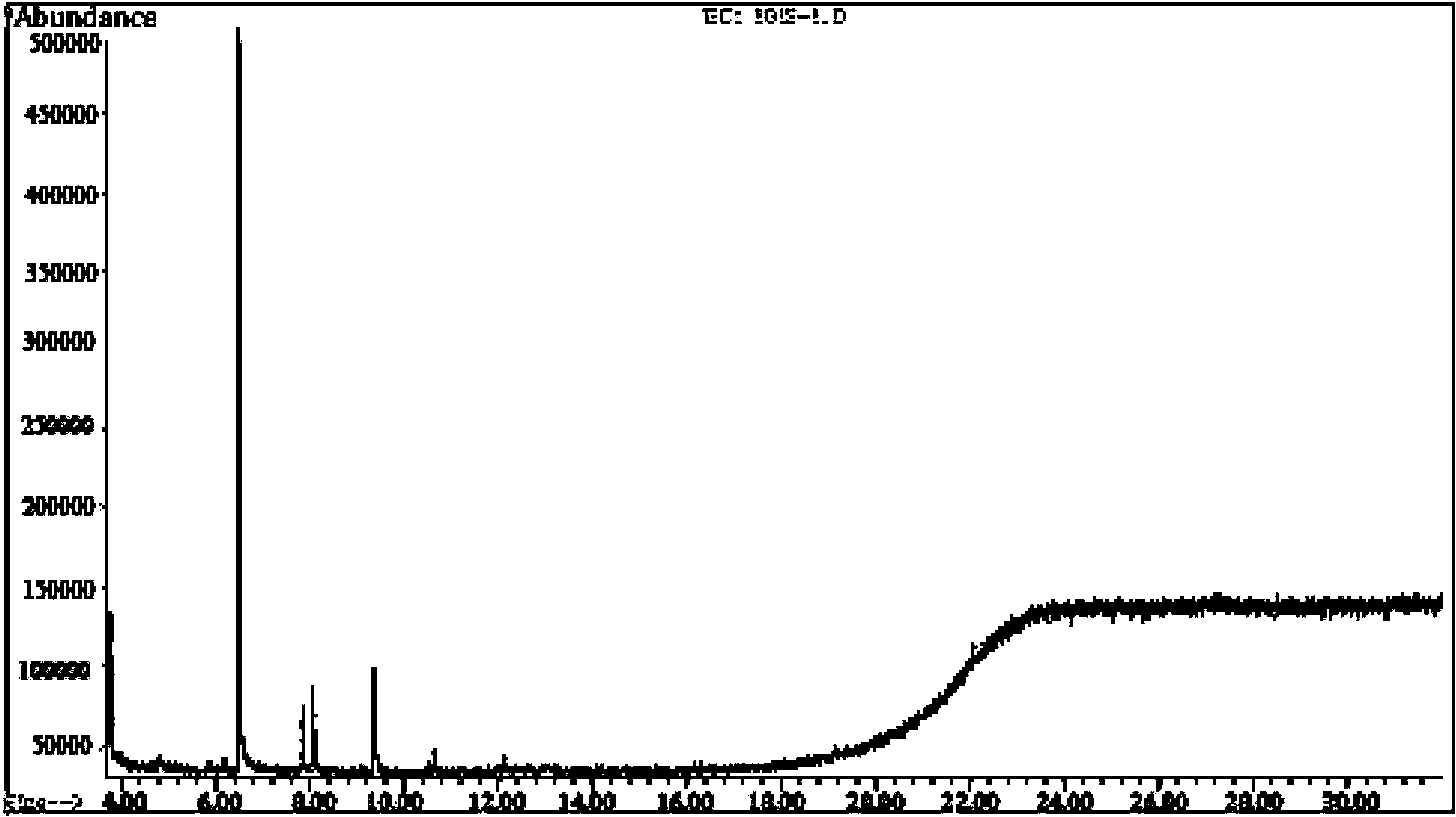

Image

Examples

Embodiment 1

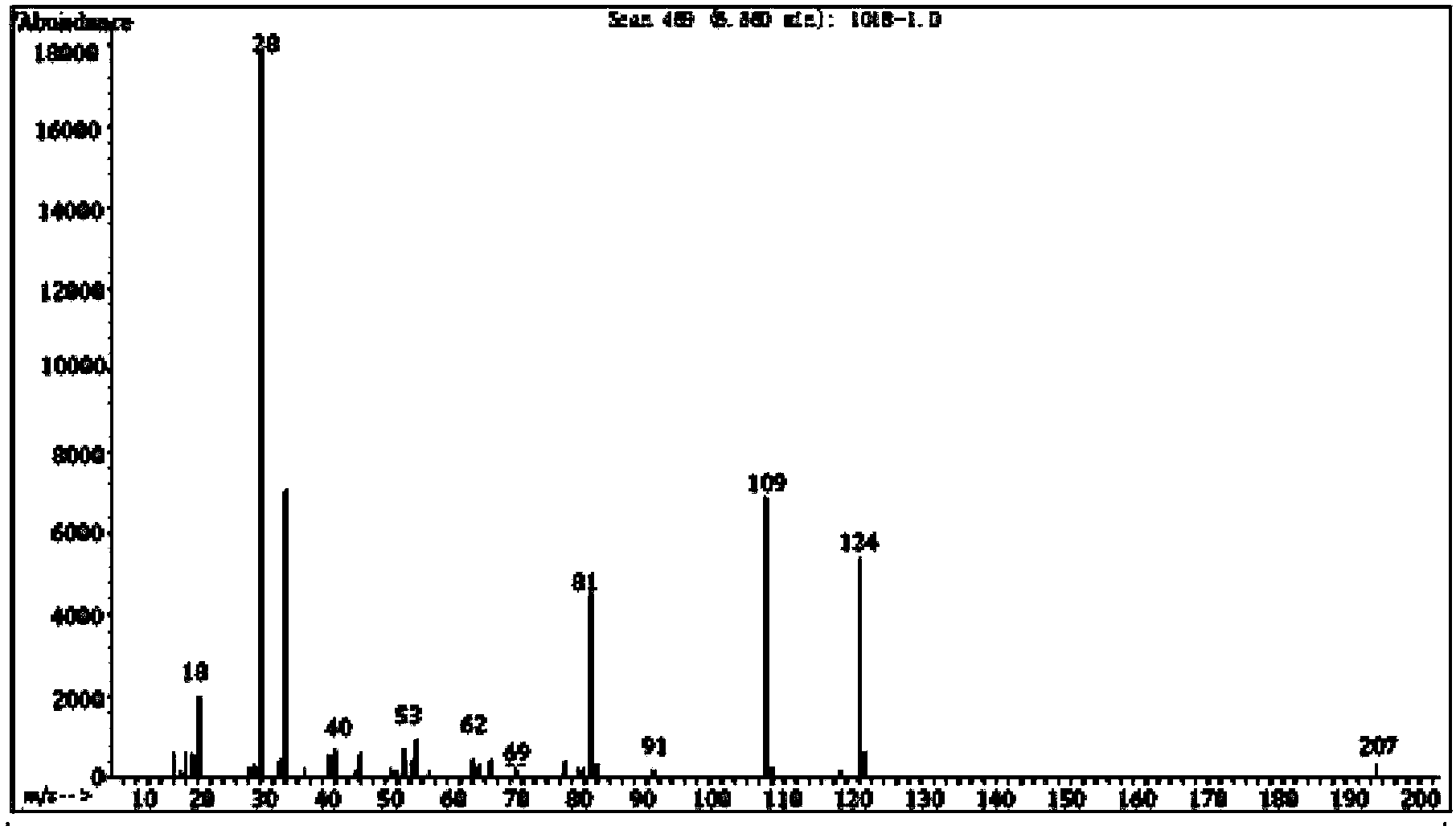

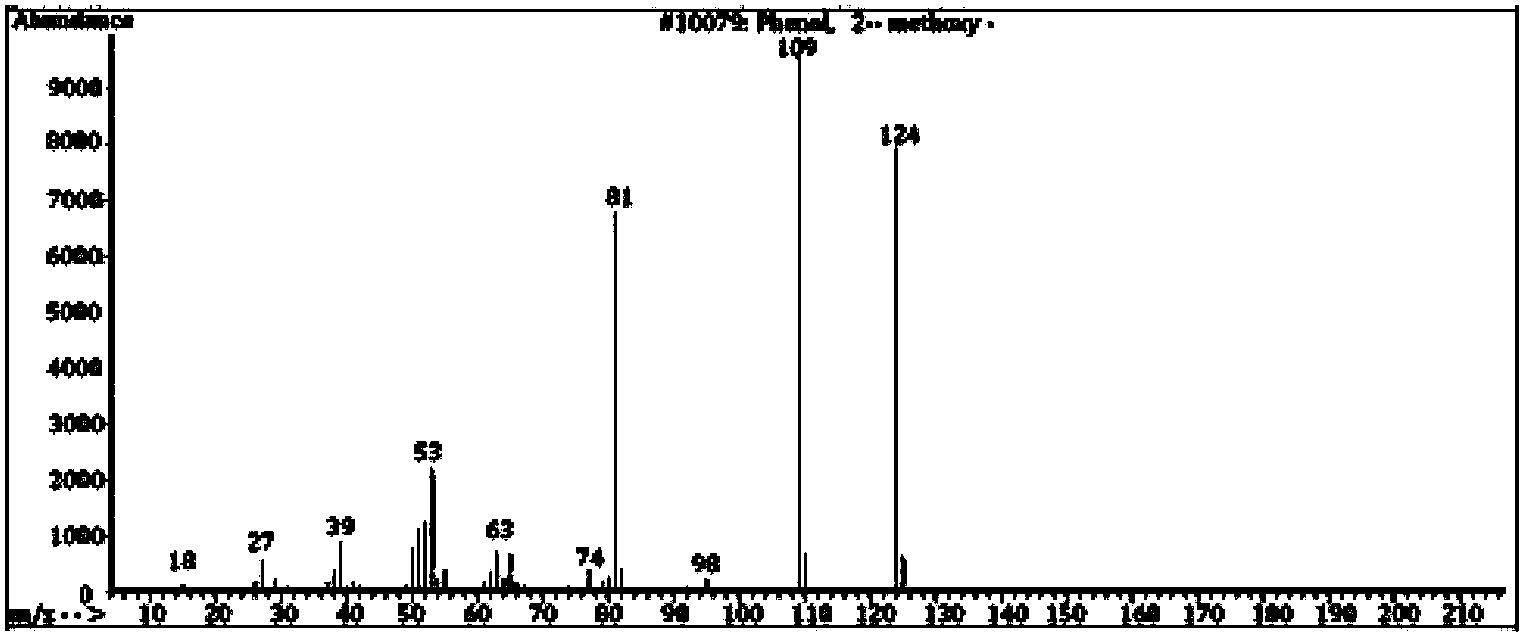

[0027] First, mix 0.5g of alkali lignin with 70mL of deionized water, put it into the autoclave, protect it with nitrogen, make the initial pressure in the autoclave 0 MPa, raise the temperature to 250°C, and stir for 5 hours. After the reaction, pump filtered, extracted with dichloromethane, and then rotary evaporated to obtain o-methoxyphenol;

[0028] Add 0.5g of o-methoxyphenol and 70mL of aqueous hydrochloric acid solution with pH=1.8 into the reaction kettle, when the reaction atmosphere is H 2 , the initial pressure is 1MPa, the temperature is raised to 280°C, the reaction time is 3h, the conversion rate of o-methoxyphenol is 100%, and the yield of catechol is 90%.

Embodiment 2

[0030]First, mix 0.5g of alkali lignin with 70mL of deionized water, put it into the autoclave, protect it with nitrogen, make the initial pressure in the autoclave 0MPa, raise the temperature to 350°C, stir and react for 3h, after the reaction, pump filtered, extracted with dichloromethane, and then rotary evaporated to obtain o-methoxyphenol;

[0031] Add 0.5g of o-methoxyphenol and 70mL of aqueous hydrochloric acid solution with pH=1.5 into the reaction kettle, when the reaction atmosphere is H 2 , the initial pressure is 0.5MPa, the temperature is raised to 280°C, the reaction time is 3h, the conversion rate of o-methoxyphenol is 93%, and the yield of catechol is 84%.

Embodiment 3

[0033] First, mix 0.5g of alkali lignin with 70mL of deionized water, put it into the autoclave, protect it with nitrogen, make the initial pressure in the autoclave 0 MPa, raise the temperature to 300°C, and stir for 4 hours. After the reaction, pump filtered, extracted with dichloromethane, and then rotary evaporated to obtain o-methoxyphenol;

[0034] Add 0.5g of o-methoxyphenol and 70mL of aqueous hydrochloric acid solution with pH=1.8 into the reaction kettle, when the reaction atmosphere is H 2 , the initial pressure is 0 MPa, the temperature is raised to 300° C., the reaction time is 1 h, the conversion rate of o-methoxyphenol is 83%, and the yield of catechol is 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com