Mechanical power device taking spring as power source

A mechanical power and power source technology, applied in the field of mechanical power equipment and mechanical power devices, can solve the problems of large energy storage self-loss, low efficiency, and small energy storage capacity, and achieve reasonable structural design, overcome internal friction, and reliable mechanical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

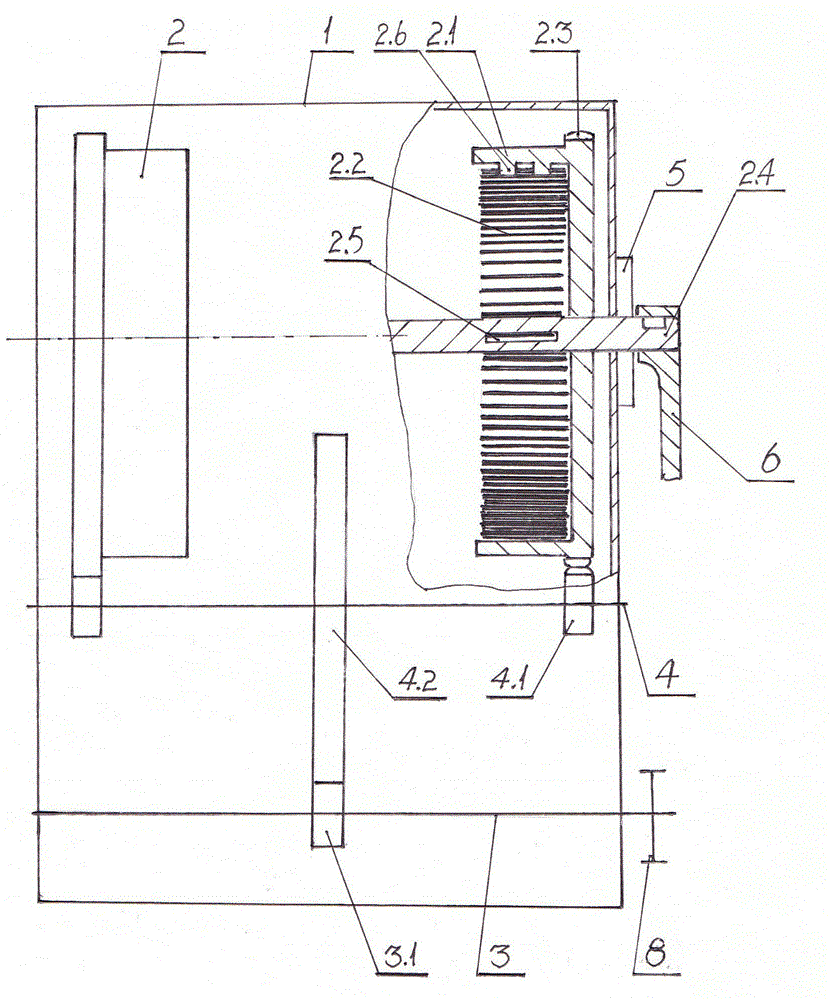

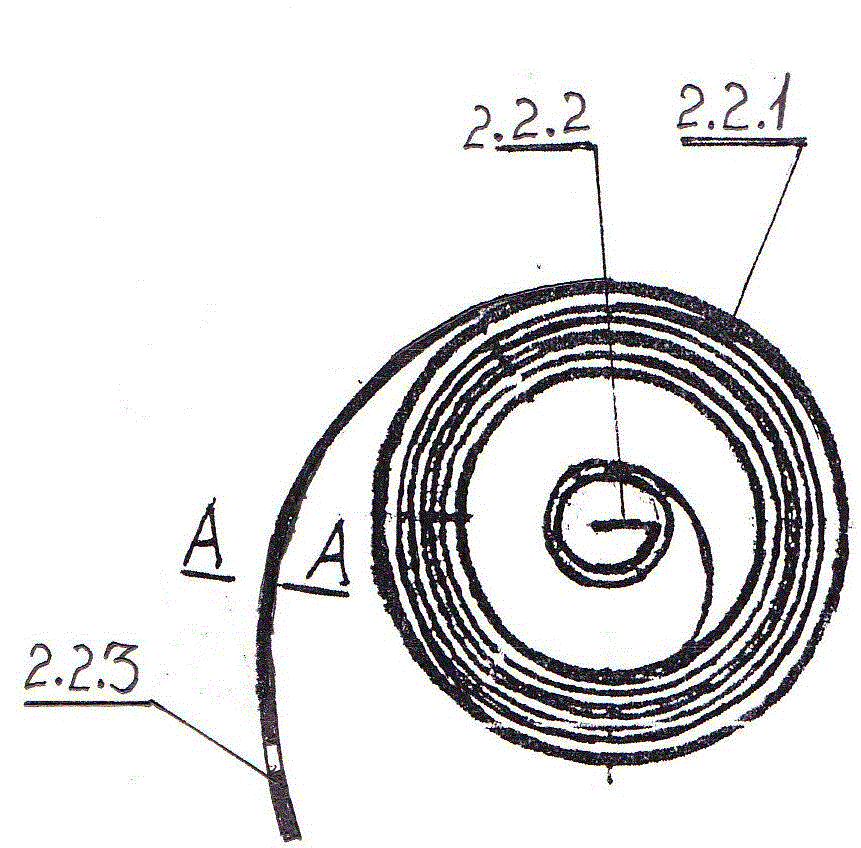

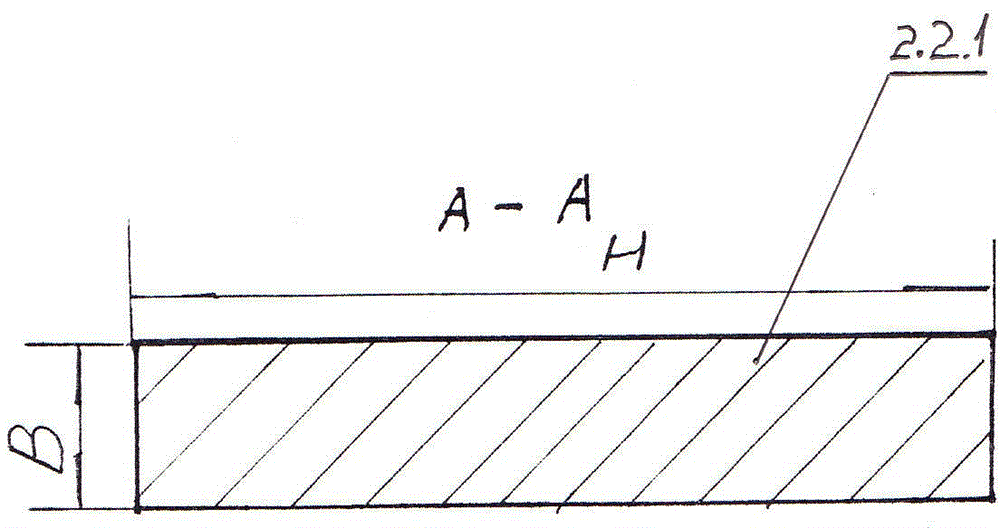

[0034] A mechanical power device using a spring as a power source according to Embodiment 1 of the present invention (see figure 1 , figure 2 , image 3 ), it is based on the premise of developing a mechanical power bicycle on the basis of existing ordinary bicycles. The power used by the mechanical power bicycle is a mechanical power device using a spring as a power source. It includes a frame 1, which is installed on the frame. The power converter group 2 and the power output shaft 3 on the 1, the mechanical power device is a power converter group 2 composed of two power converters composed of a winding motive power spring 2.2 in series. The transmission gear 2.3 of the power converter is meshed and connected with the transition gear 4.1 coaxially arranged on the transition shaft 4, respectively, and the transmission gear 4.2 on the transition shaft 4 is meshed with the power input gear 3.1 on the power output shaft 3. Connected; the power conversion The device is compos...

Embodiment 2

[0041] A mechanical power device using a spring as a power source according to Embodiment 2 of the present invention (see image 3 , Figure 4 , Figure 5 ), it is based on the premise of developing a mechanical power motorcycle on the basis of existing ordinary motorcycles. The power used by the mechanical power motorcycle is a mechanical power device using a clockwork as a power source. It includes a frame 1, a mounting The power converter group 2 and the power output shaft 3 on the frame 1, the mechanical power device is a power converter group 2 composed of two power converters composed of a winding prime force spring 2.2 connected in series, The power converter group 2 is a main power converter 21 and an auxiliary power converter 22. The transmission gear 2.3 of the main power converter 21 is meshed with the power input gear 3.1 on the power output shaft 3. The auxiliary power converter 22 There is no transmission gear 2.3, the end of the barrel 2.1 is provided with a w...

Embodiment 3

[0050] A mechanical power device using a spring as a power source according to Embodiment 3 of the present invention (see image 3 , Figure 4 , Figure 5 , Image 6 ), it is based on the premise of satisfying the development of the fan in the existing mining machinery and equipment. The power used by the fan in the mining machinery and equipment is a mechanical power device using a clockwork as a power source. It includes a frame 1, installed in the The power converter group 2 and the power output shaft 3 on the frame 1, the mechanical power device is a power converter group 2 composed of three power converters composed of a winding prime power spring 2.2 in series. The transmission gears 2.3 of the three power converters are respectively meshed with the transition gears 4.1 arranged coaxially on the transition shaft 4, and the transmission gear 4.2 on the transition shaft 4 is meshed with the power input gear 3.1 on the power output shaft 3. There is a power converter gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com