Internal structure of automatic ice falling equipment of ice machine

An ice machine and automatic technology, which is applied in ice making, lighting and heating equipment, ice storage/distribution, etc., can solve the problems that automatic ice dropping cannot be realized, and achieve a small and beautiful body, not easy to stick, and smooth ice dropping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

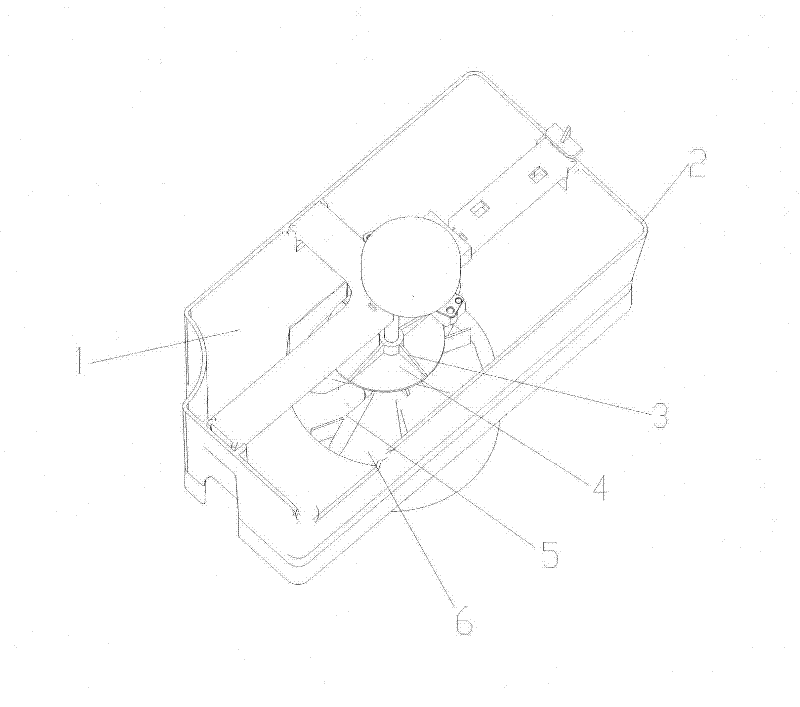

[0011] like figure 1 As shown, the internal structure of the automatic ice removal device for the ice machine includes an ice storage box 2 and a main turntable 6, a sliding plate 1 is provided inside the ice storage box, and a main drive shaft is provided at the center of the ice storage box. A main turntable 6 and an auxiliary turntable 4 are respectively installed on the main drive shaft, and a main ice stirring impeller 5 is arranged above the main turntable.

[0012] The sliding plate 1 is arranged around the ice storage box, and a sliding wall is formed inside the ice storage box, and the inclination range of the surrounding sliding wall can reach 0-180 degrees.

[0013] The height of the main ice stirring impeller 5 is 0.5-100mm, and the width is 0.5-15mm.

[0014] The height of the ice stirring impeller 3 is 0.5-60mm, and the width is 0.5-15mm.

[0015] When working, the inner sliding plate can easily send the ice cubes into the two turntables, and the turntables are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com