Method for fabricating waveguide type surface plasma resonance sensor chip

A surface plasmon and resonance sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve problems such as production difficulties, achieve low cost, and meet the effect of preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, prepare the patterned convex film, waveguide ink, and gold ink. Among them, the waveguide ink has a viscosity of 11-15 s and contains a waveguide polymer with a mass fraction of 10%-25%. In this embodiment, the waveguide ink is a fluorinated polyimide solution with a mass fraction of 10% and a viscosity of 11s. The gold ink is a gold suspension with a mass fraction of 10%. .

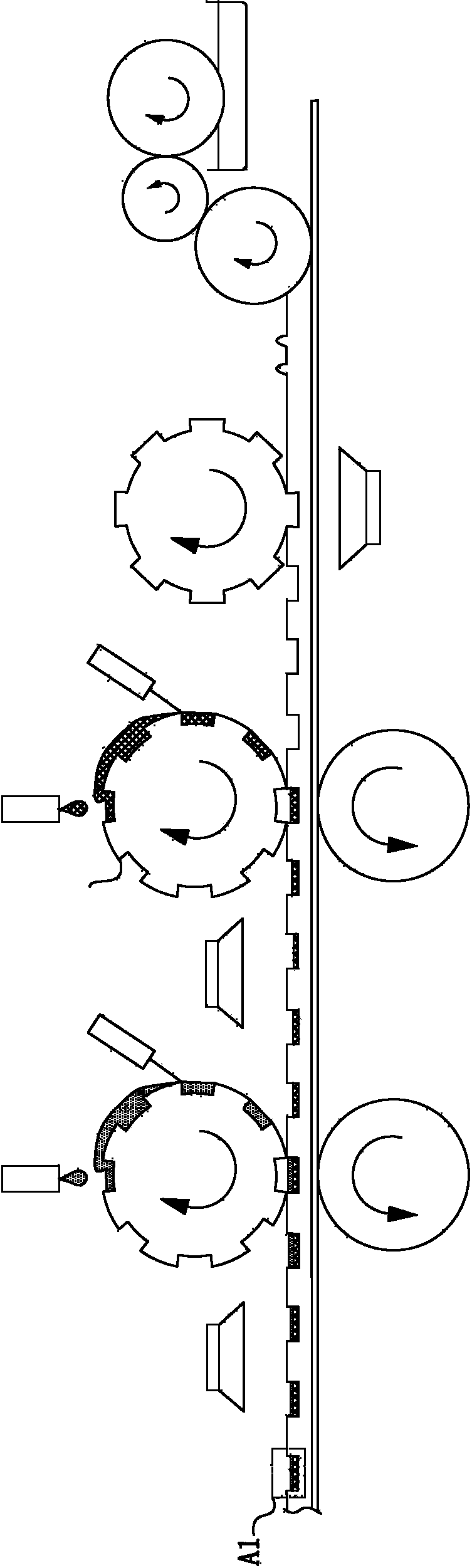

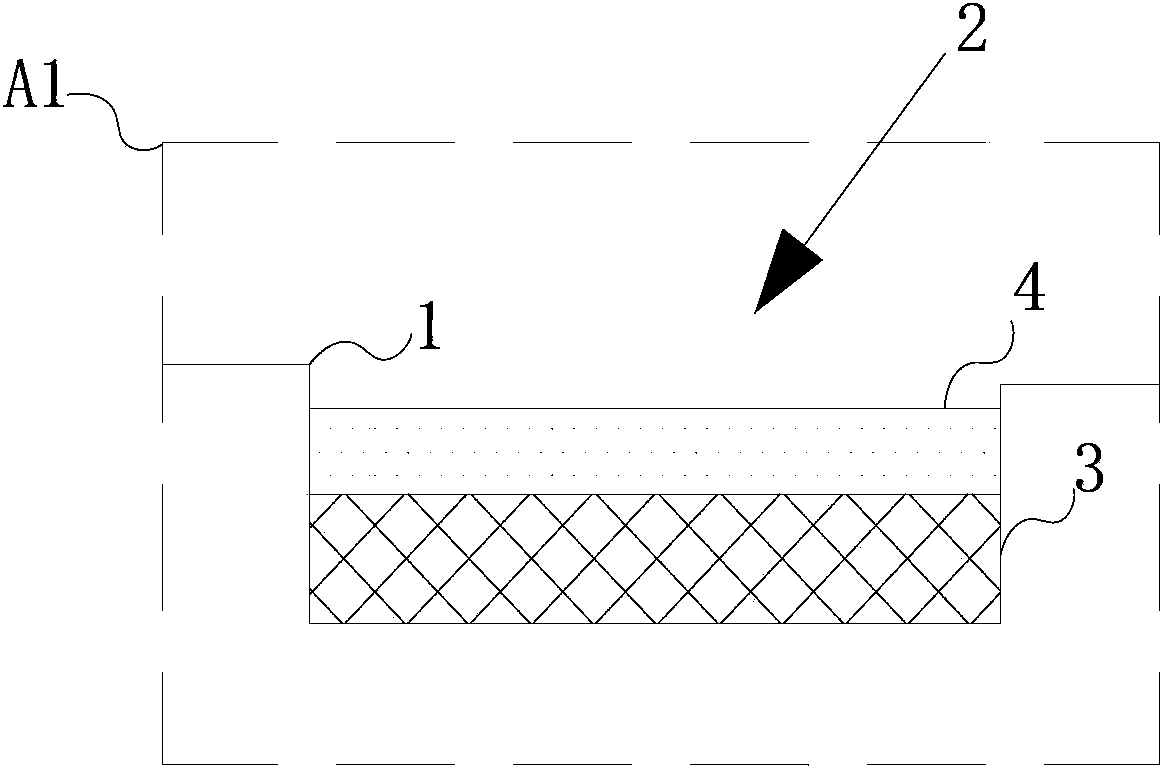

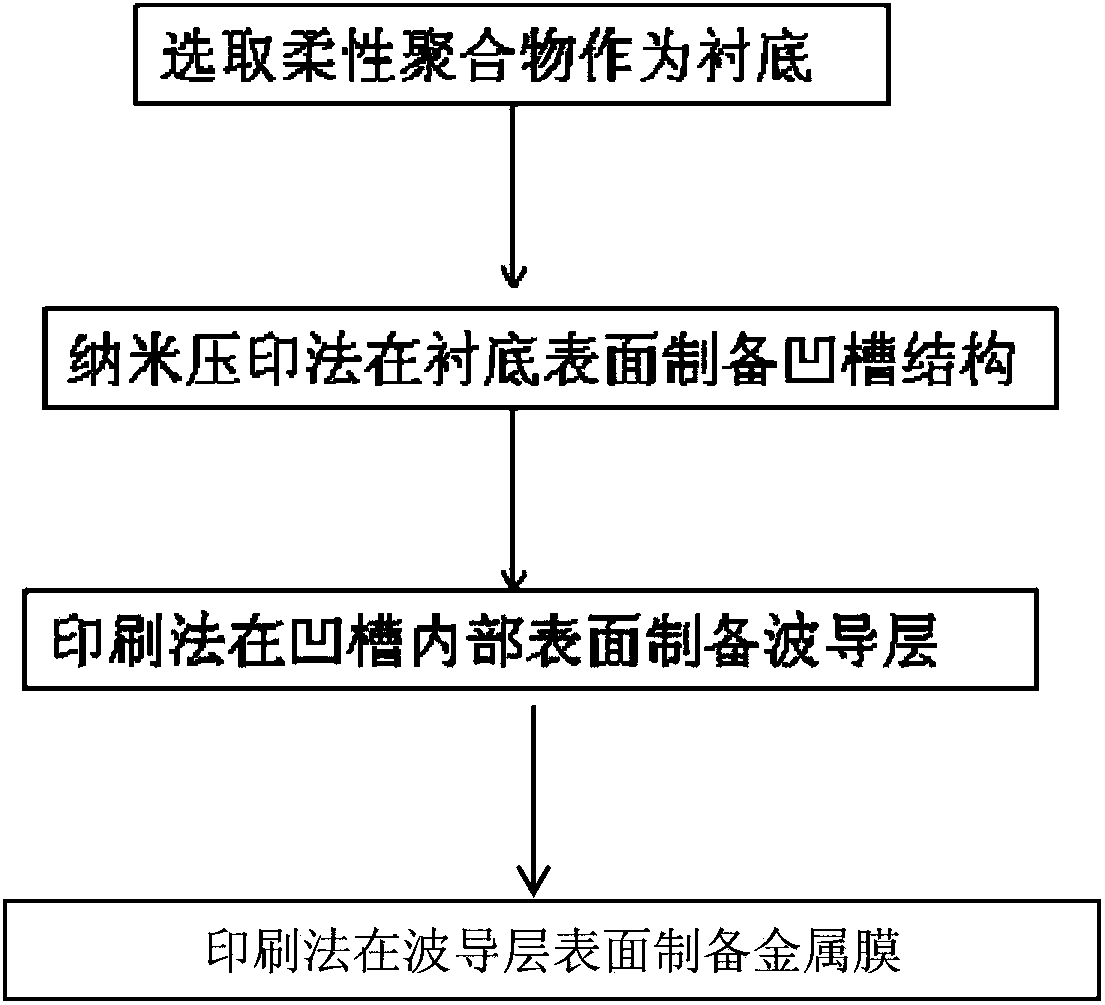

[0028] In the second step, in this embodiment, the roll-to-roll roller imprinting method commonly used in the nanoimprinting method is used to make the groove 2 . The pattern of the convex membrane is imprinted onto the flexible substrate 1 by a nanoimprint method. The groove 2 of the SPR sensor of this embodiment is formed on the flexible substrate 1 . The pattern of the groove 2 is complementary to the pattern of the convex film.

[0029] The third step is the manufacturing process of the waveguide layer 3 . This step is to uniformly print a layer of waveguide material on the bottom ...

Embodiment 2

[0033] The manufacturing steps of this embodiment are different from those of Embodiment 1 in that: in the second step, a planar embossing method is used to manufacture the groove 2 . And polyethylene terephthalate (PET) is selected as the material of the flexible substrate 1 .

[0034] The third step is to use perfluorinated cyclobutyl (PFCB) aryl ether solution with a mass fraction of 12% and a viscosity of 15s as the material of the waveguide ink, and make it into the groove 2 by gravure printing to form a uniform layer A waveguide layer with a thickness of 20 μm.

[0035] The fourth step is to use one of the aluminum suspensions with a mass fraction of 13% as a metal ink to print and form a film. In this embodiment, a metal film 4 made of aluminum with a thickness of 50 nm is formed by accurately spraying to the bottom of the groove 2 by means of gravure printing.

[0036] Please refer to Example 1 for the remaining preparation steps.

Embodiment 3

[0038] The manufacturing steps of this embodiment are different from those of Embodiment 1 in that: in the second step, a planar embossing method is used to manufacture the groove 2 . And polyethylene terephthalate (PEN) is selected as the material of the flexible substrate 1 . The third step is to use a halogenated polyacrylate solution with a mass fraction of 15% and a viscosity of 13s as the waveguide ink, and make it into the groove 2 by aerosol jet printing to form a uniform waveguide layer with a thickness of 30 μm. . The fourth step is to use the copper suspension with a mass fraction of 15% as the metal ink to print the film. In this embodiment, aerosol spray printing is used to accurately print to the bottom of the groove 2 to form a copper metal film 4 with a thickness of 70 nm.

[0039] Please refer to Example 1 for the remaining preparation steps.

[0040] In other embodiments, the flexible substrate 1 is made of some high refractive index organic polymers, such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com