Fully automatic paving and planting combination machine of multiline grass square lattice sand barriers

A fully automatic and combined machine technology, applied in botany equipment and methods, horticulture, applications, etc., can solve problems such as high operating costs, inconvenience, and lack of economical, efficient, and reliable technology and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

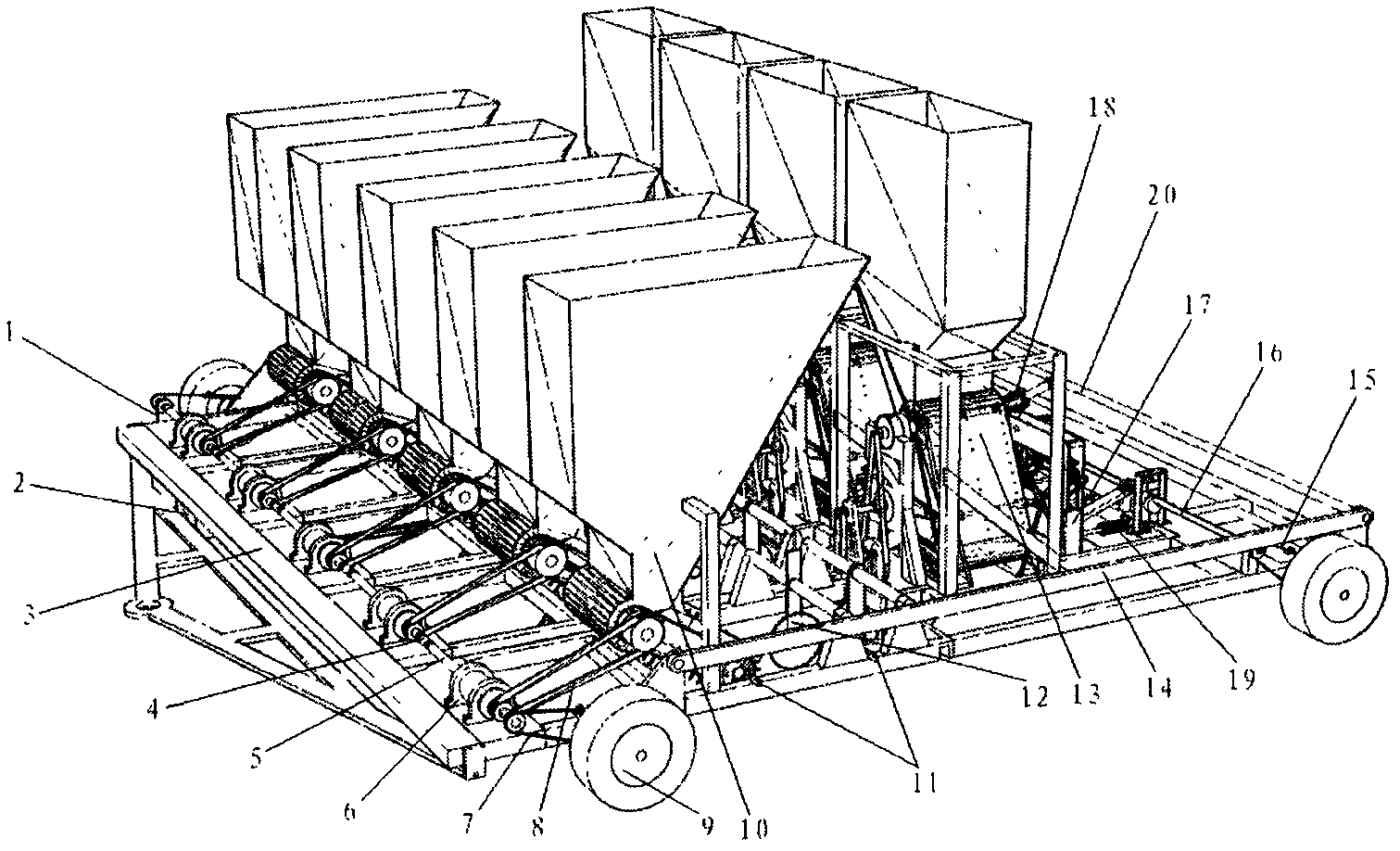

[0023] Example 1: Combining Figure 1-Figure 7 , the present invention is a multi-row grass square sand barrier fully automatic laying and planting combined machine, which is composed of a walking and supporting system, a longitudinal grass laying-planting system, a horizontal grass laying system, a horizontal shovel pressure planting system, a detection and synchronous booster system and The frame is composed of a walking and supporting system, a longitudinal grass laying-planting system, a horizontal grass laying system, a horizontal shovel pressure planting system, and a detection and synchronous assist system.

[0024] The present invention also has the following technical characteristics:

[0025] The walking and supporting system comprises a supporting walking wheel lifting linkage device (14), a supporting walking wheel (9) and a supporting walking wheel lifting power cylinder (18), and the supporting walking wheel lifting and falling linkage device (14) is installed on...

Embodiment 2

[0033] Example 2: Combining Figure 1 to Figure 7 , the present invention is driven by a large tractor. In this embodiment, there are 5 vertical grass-planting systems, 4 horizontal grass-laying systems and 4 horizontal shovel pressure planting systems, and the specific numbers of the above-mentioned three systems are determined by the actual working conditions and the selected traction machinery. Among them, 5 longitudinal grass-laying devices are connected to each other through the drive shaft coupling of the longitudinal grass-laying device; 4 horizontal grass-laying systems are connected to each other through the drive transmission of the horizontal grass-laying device; The device offset slider crank mechanism and the cam mechanism drive shaft are connected with each other.

[0034] The vertical laying and planting process of the grass grid is as follows:

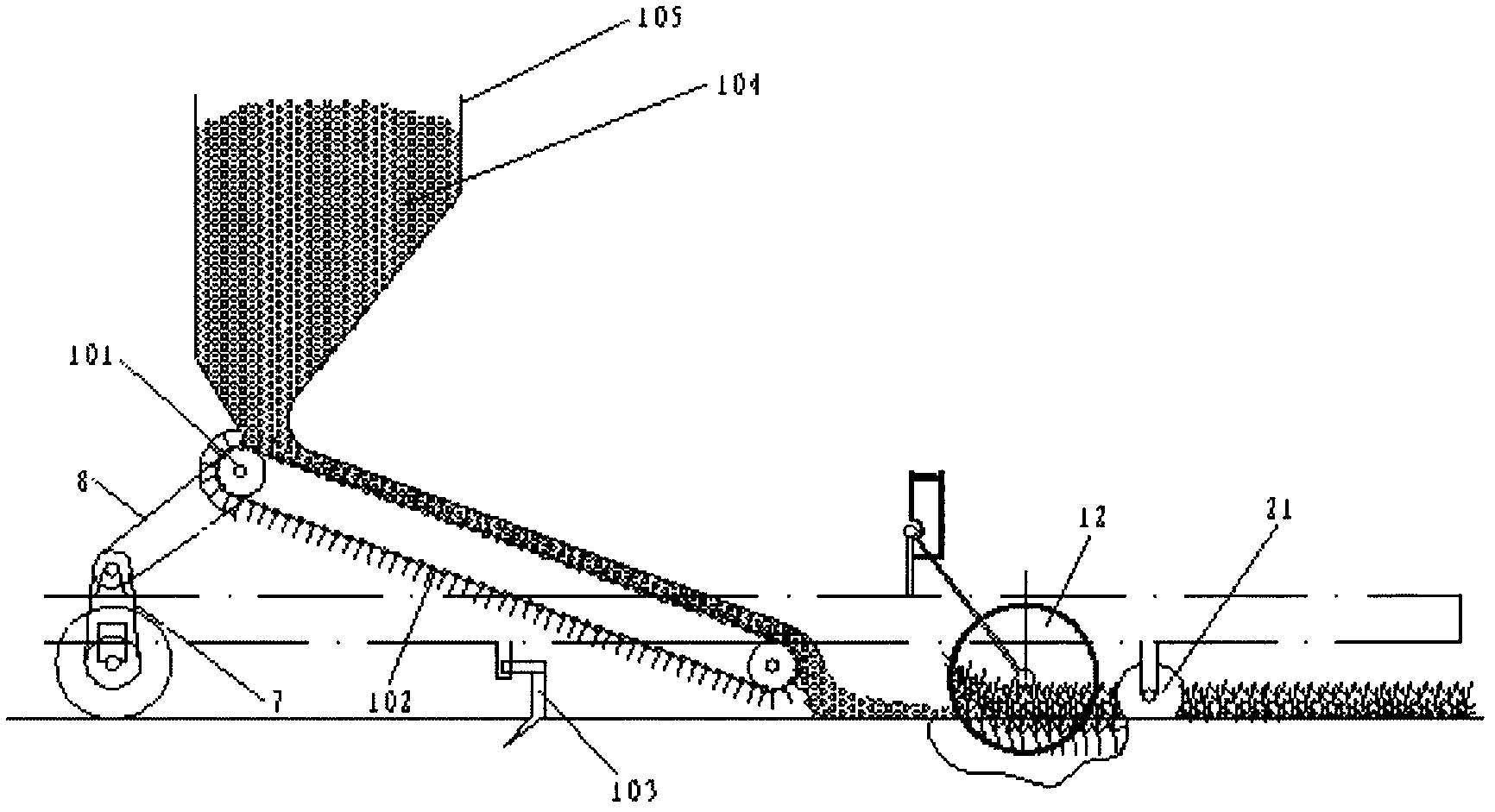

[0035] The longitudinal grass-laying device (10) obtains the grass-laying drive sprocket (101) from the supporting ...

Embodiment 3

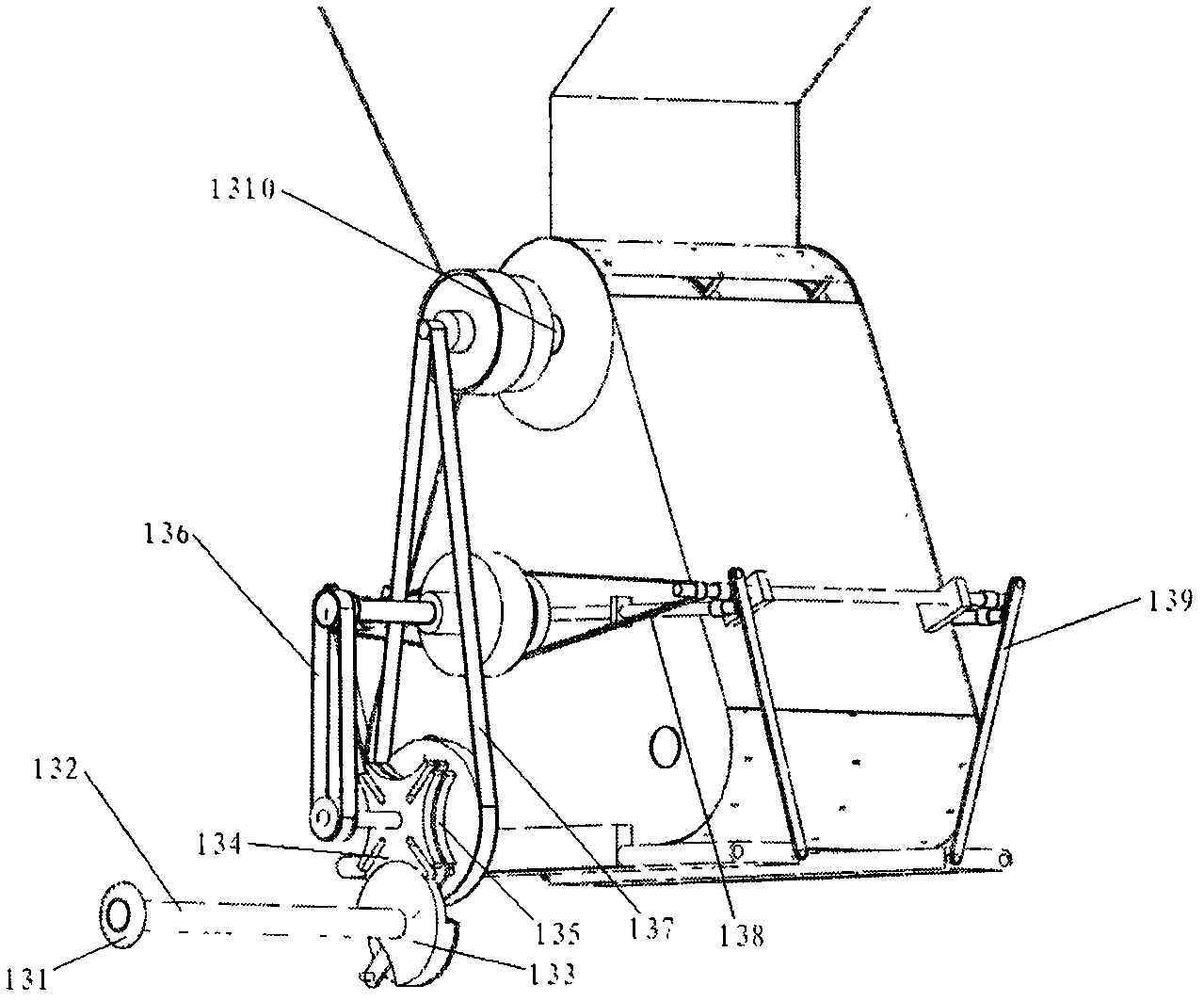

[0051] Example 3: Binding Figure 1-Figure 7, the present invention is a multi-row grass grid sand barrier fully automatic laying-planting technology and combined machine, the so-called "multi-row" means at least two rows, there is no requirement for the maximum number of rows, any number can be selected according to actual working conditions and Depends on the traction machinery. The offset crank slider mechanism (174) reciprocates on the slideway (175) at a certain speed under the drive of the drive shaft (16). Guarantee that horizontal grass laying device (17) is zero with ground relative velocity in working stroke. The described transverse grass-laying device (13) reasonably distributes the power to the transverse grass-laying device through the power-driven sheave sets (133), (134), (135) transmitted through the drive force distribution shaft (29) of the transverse grass-laying mechanism. Grass laying drive sprocket (1310) and grass falling mechanism (139), both of them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com