Preparation method and application of MgO (111) load nickel-base catalyst

A catalyst and nickel-supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of catalyst bed pressure rise, insufficient stability, and catalyst Deactivation and other problems, to achieve the effect of prolonging catalyst life, preventing sintering, and resisting carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

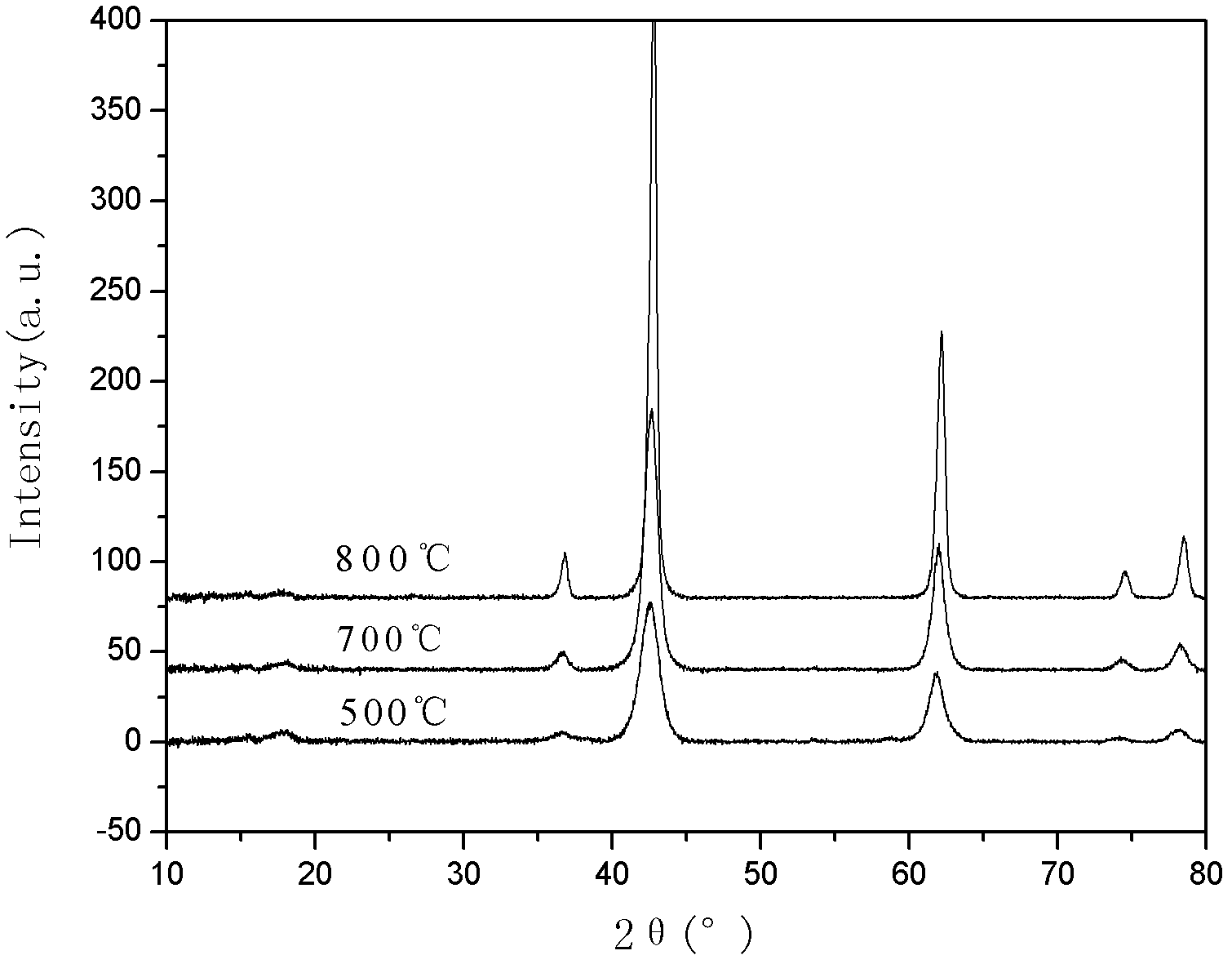

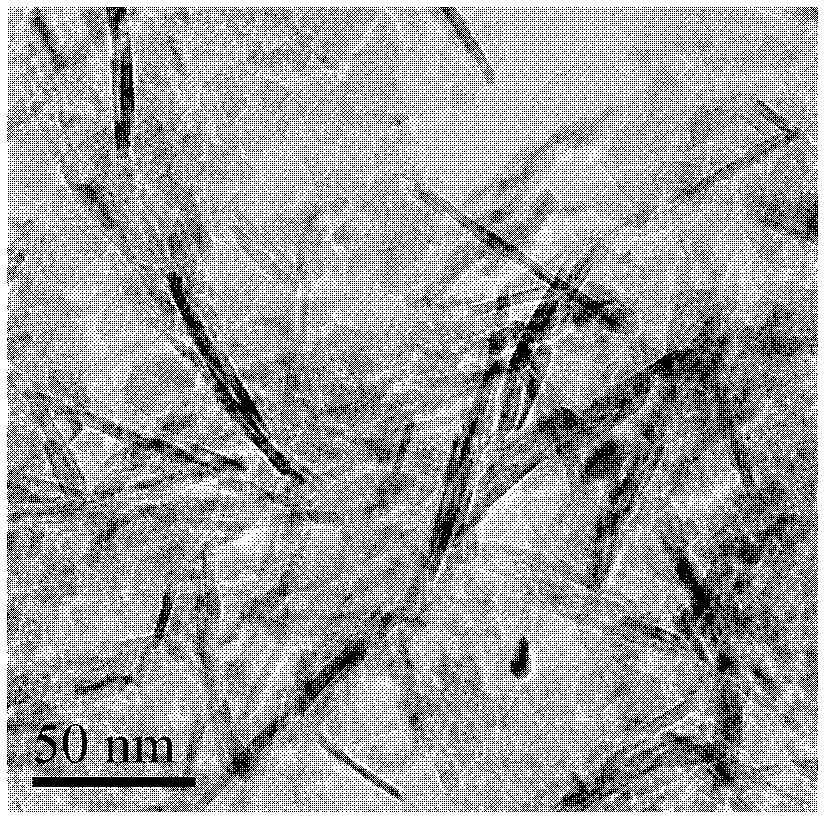

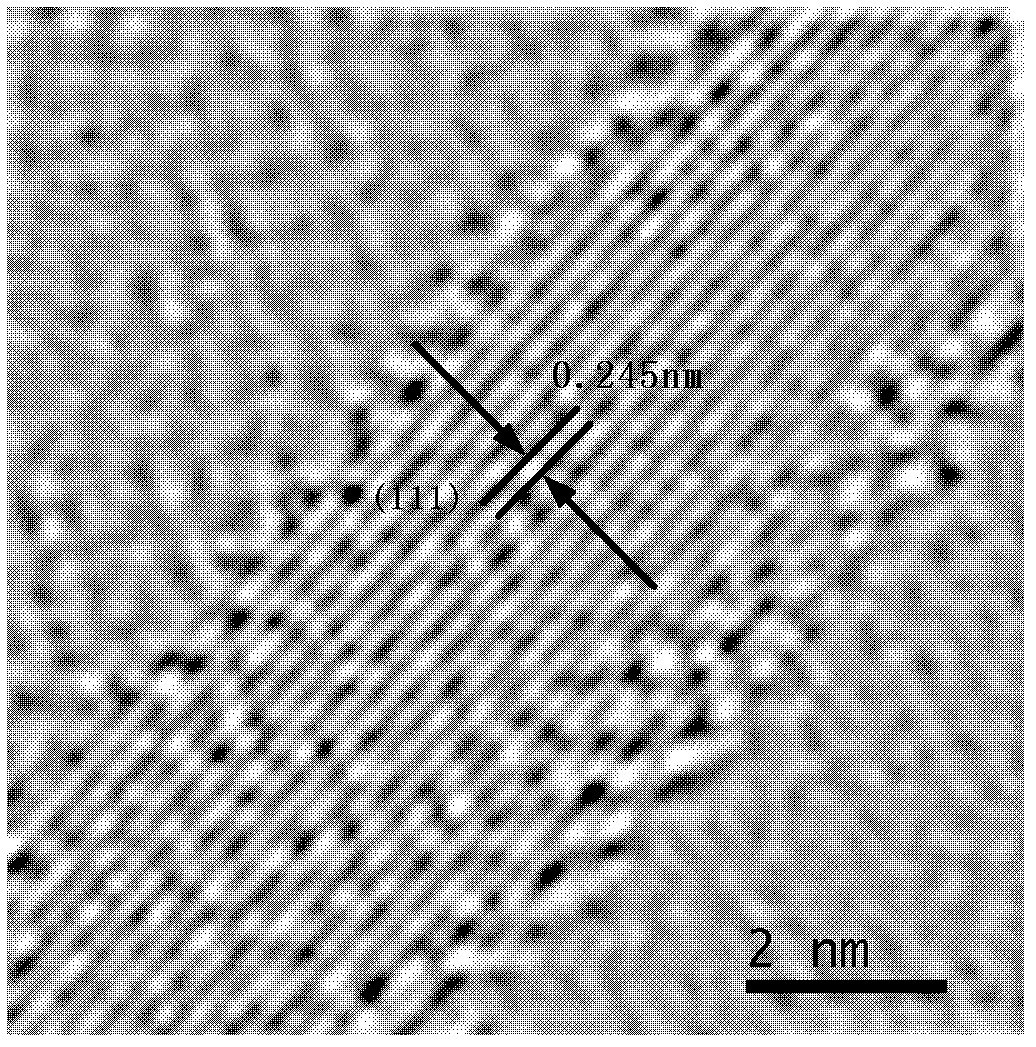

[0026] Embodiment 1, 2 is the embodiment prepared by MgO(111) supported nickel-based catalyst;

[0027] Embodiment 3, 4 is the embodiment that the catalyst prepared by investigating embodiment 1, 2 is used for methane carbon dioxide reforming reaction activity under different temperatures;

Embodiment 5

[0028] Example 5 is an example of the service life of the catalyst prepared in Example 1 for the carbon dioxide reforming reaction of methane at 750° C.;

Embodiment 6

[0029] Example 6 (comparative example) is an example for investigating the service life of commercial MgO-supported nickel-based catalysts for the carbon dioxide reforming reaction of methane catalyzed at 750°C.

[0030] Example 1

[0031] A preparation method of MgO(111) supported nickel-based catalyst, the steps are as follows:

[0032] (1) Synthesis of MgO(111) carrier:

[0033] Dissolve 3.6g of magnesium strips in 159mL of anhydrous methanol, then add 10.36g of structure-directing agent p-methoxybenzyl alcohol, stir for 5h, then add water-in-methanol solution (formed by mixing 5.4g of water and 110mL of methanol) dropwise ), stirring at the same time to make the magnesium methoxide hydrolyze, continue to stir for 12h after the dropwise addition, then put it into a high-pressure reactor, first feed argon to exhaust the air in the kettle, and then continue to feed argon until the pressure in the kettle is 1.0MPa , heated to 265°C and reacted under supercritical conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com