Universal corrugated lining plate for horizontal mill

A mill and liner technology, which is applied in grain processing, etc., can solve the problems affecting the output of the mill table, and achieve the effect of improving the grinding effect, increasing the output, and simplifying the processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

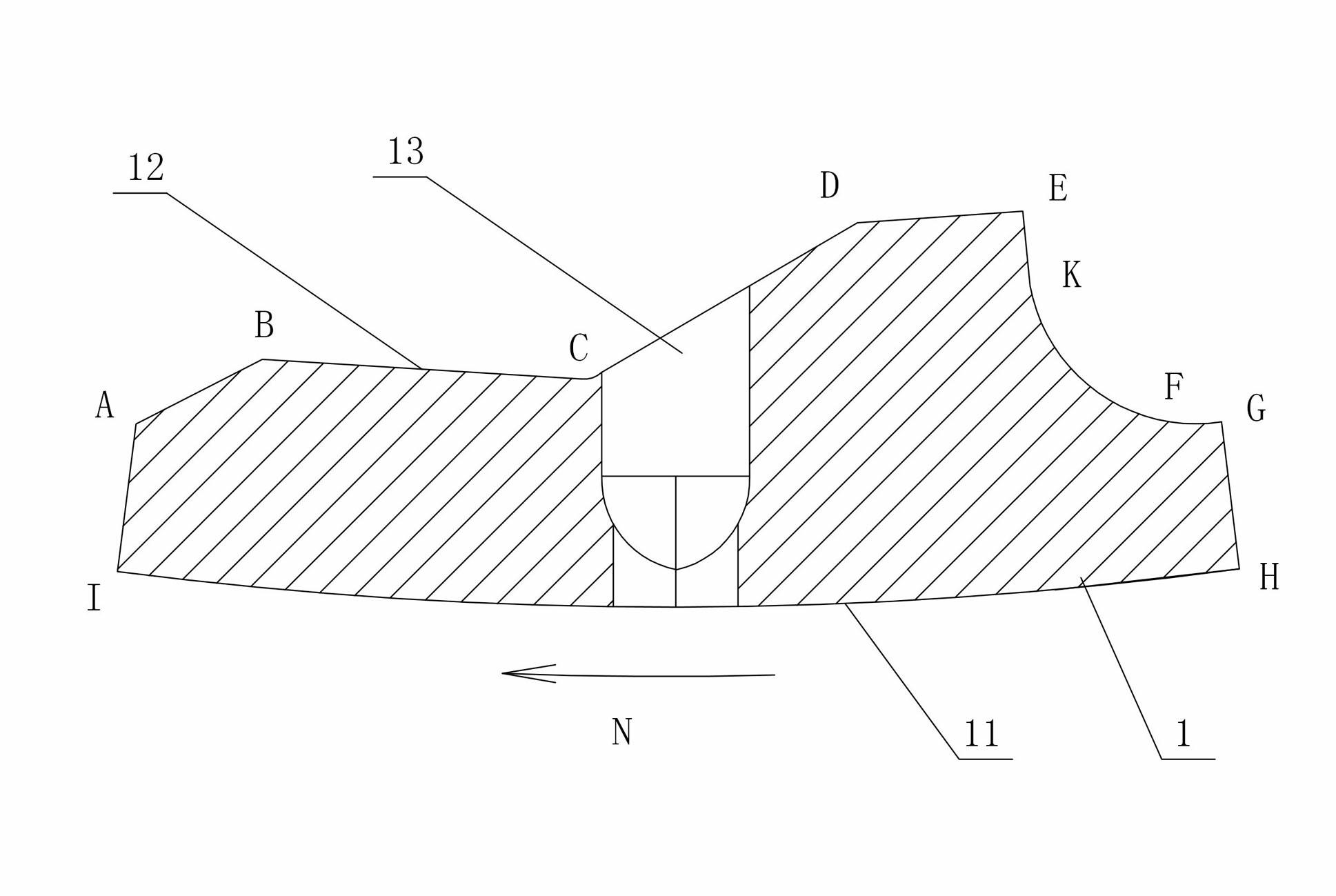

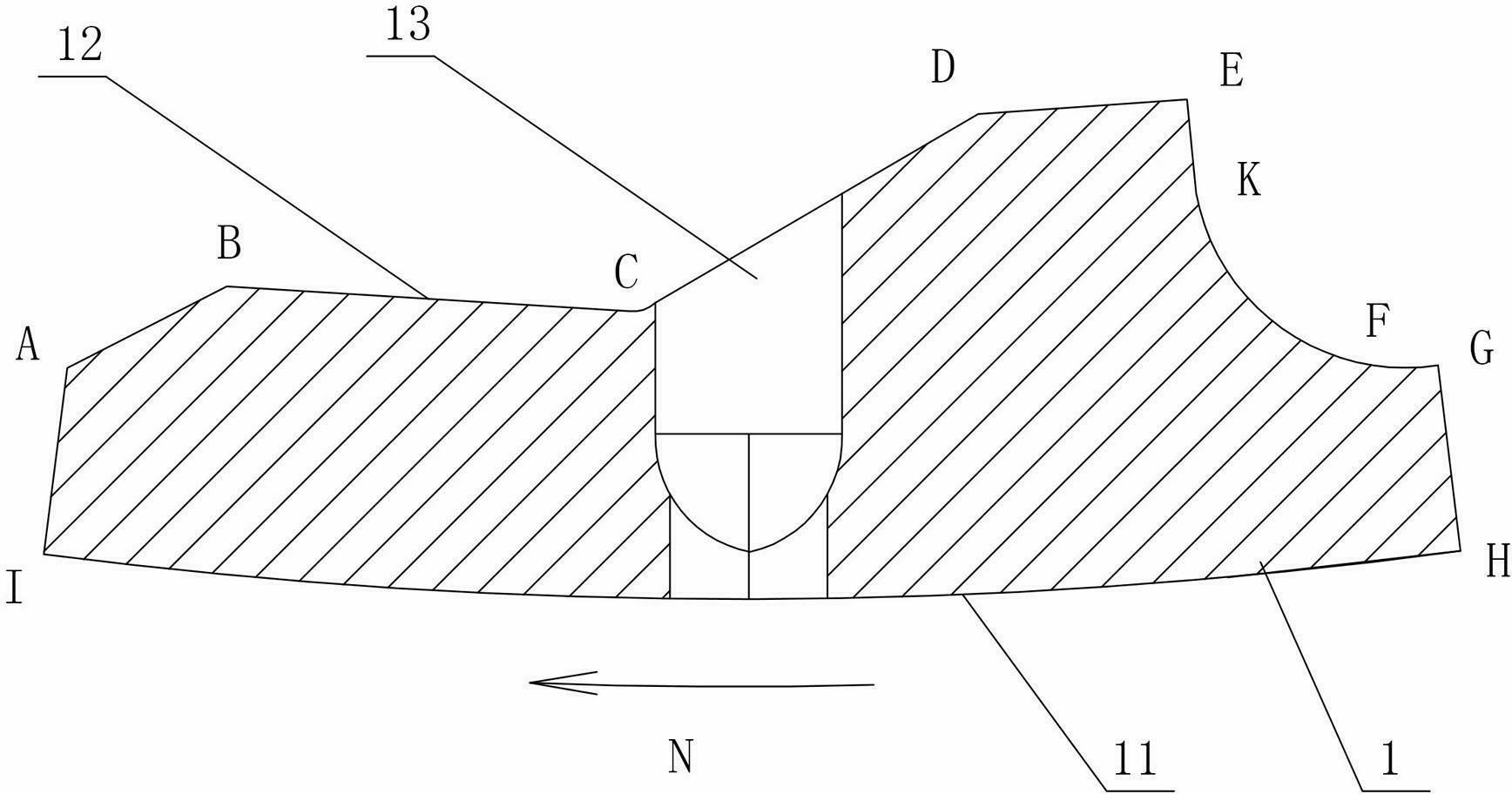

[0014] like figure 1 As shown, the universal corrugated liner for horizontal mills of the present invention includes a liner body 1, and a mounting hole 13 is opened on the liner body 1. One end of the liner body 1 is a mounting surface 11, and the other end is a grinding working surface. 12. The installation surface 11 and the grinding working surface 12 are two opposite surfaces. The grinding working surface 12 is the working surface facing the rotation center of the mill and directly in contact with the material to be ground and the medium. The installation surface 11 and the grinding working surface 12 Opposite to and facing the barrel wall of the mill, it is used to install the liner body 1. The HI section shown in the figure is the installation surface, which is in the shape of an arc, and the radius of the arc is compatible wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com