Contact force real-time control system for airbag polishing

A real-time control system and airbag polishing technology, which is applied to surface polishing machine tools, grinding/polishing equipment, and automatic grinding control devices, etc., can solve the problem that the polishing contact force cannot be controlled in real time and on-line, so as to improve the polishing effect and polishing Accuracy, stable contact force, real-time control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

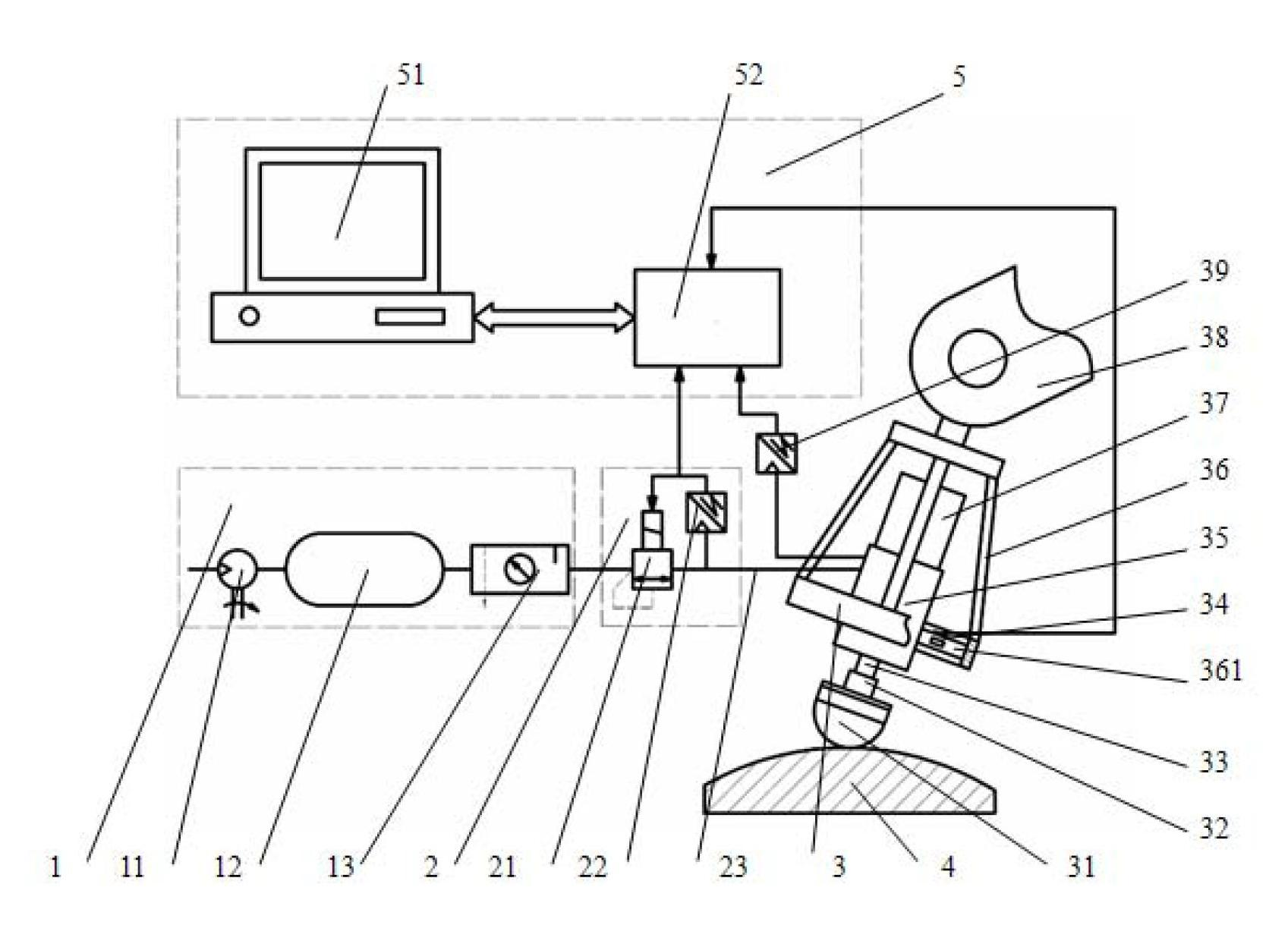

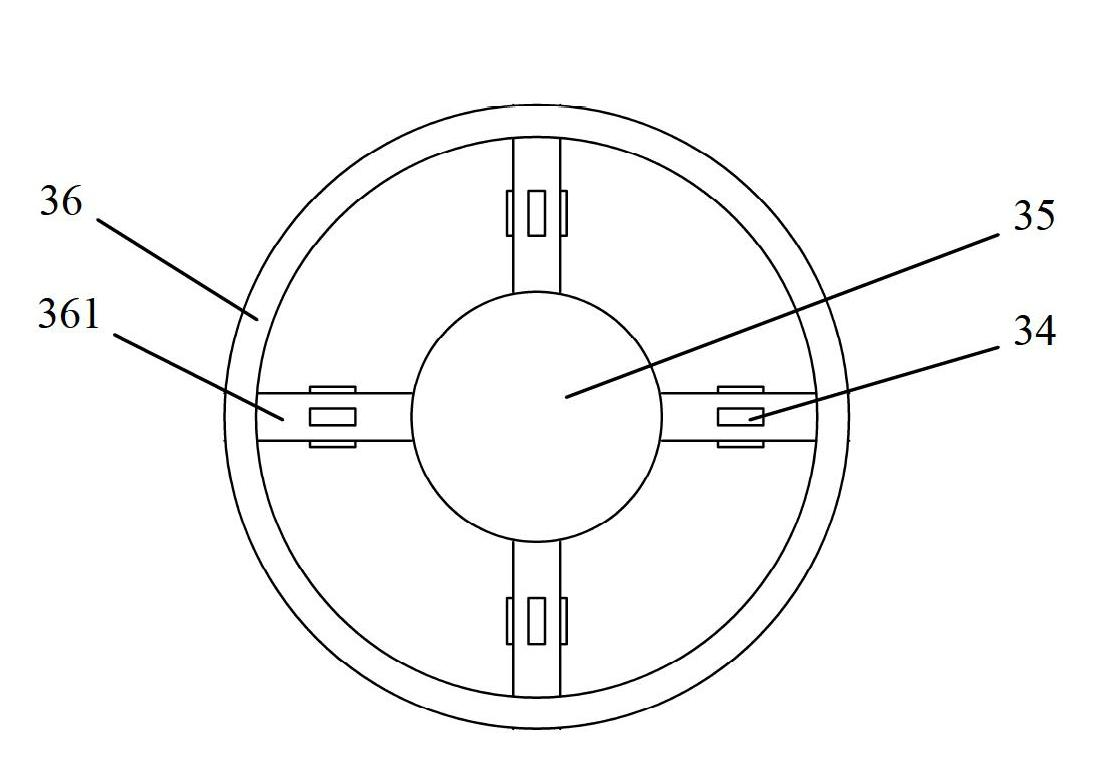

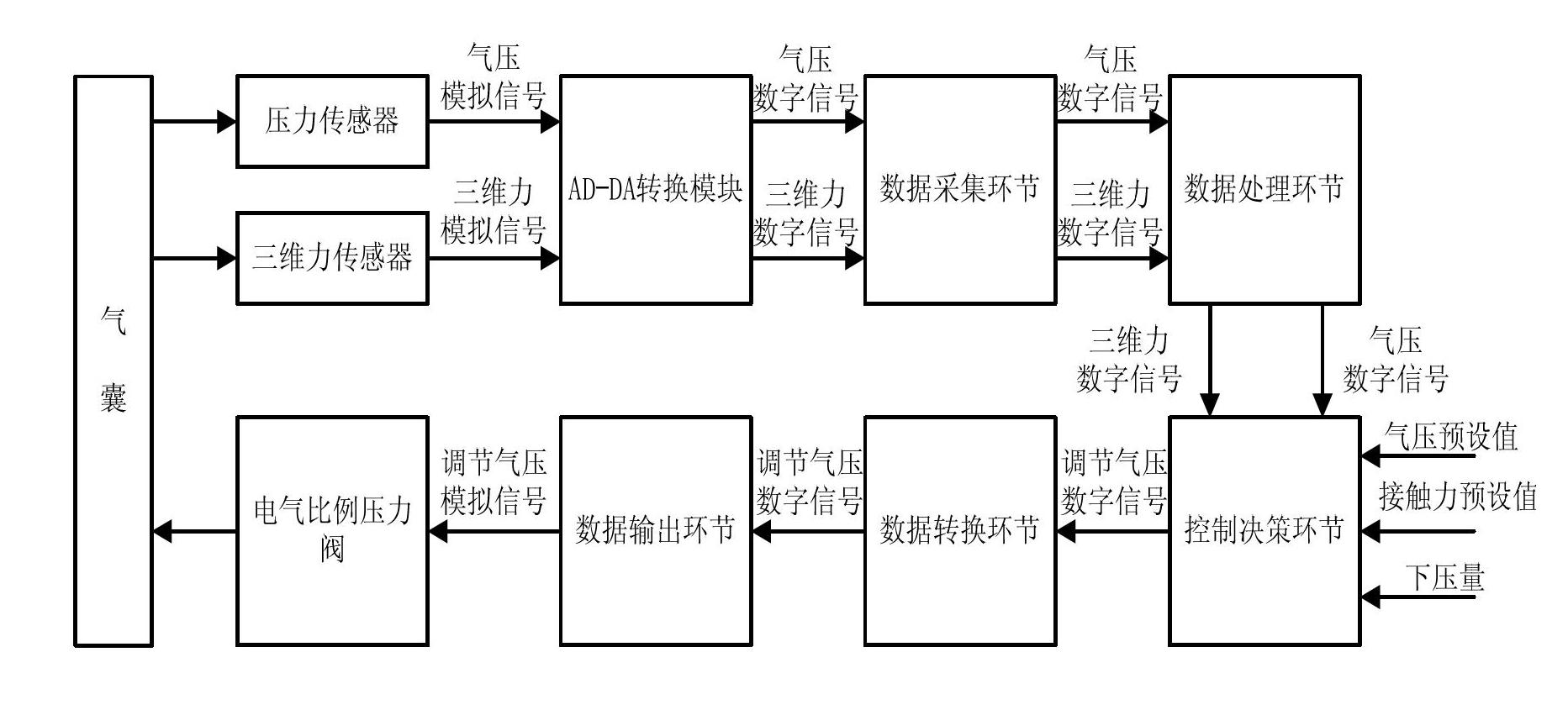

[0025] refer to Figure 1 to Figure 3 , a contact force real-time control system for airbag polishing, comprising an airbag polishing device 3, a gas source 1, an air pressure regulating device 2, and a control system 5 for real-time adjustment of the gas pressure entering the airbag; the airbag polishing device 3 includes The air bag 31 which plays a polishing role and the air chamber 35 communicated with the air source 1, the air bag 31 is fixed on a holder 32, and the holder 32 is linked with a motor 37 through a main shaft 33, and the The main shaft 33 of the main shaft is provided with the air channel that communicates with the air bag 31 and the air chamber 35; the pressure sensor 39 that detects the actual air pressure in the air chamber 35 is installed on the described air chamber 35, and the described pressure sensor 39 is connected with the described air chamber 35. The control system 5 is connected, and the air chamber 35 is connected to the end of the industrial ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com