Preparation method for hydrophobic large-size bulk nanometer porous SiO2 aerogel

An airgel and wet gel technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reducing the performance of airgel, restricting the extensiveness, and unsatisfactory thermal insulation effect, etc., and achieving easy Recycling, cost reduction, good effect of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) 10ml of pure industrial grade water glass (the substance ratio of the solution: n (Na 2 O):n(SiO 2 )=1:3.1), add 40ml of deionized water to dilute, and at room temperature, the diluted solution is passed through an exchange column (diameter 2cm×height 50cm) filled with strong acid styrene cation exchange resin to remove sodium ions and other cations in water glass . The pH value of the treated solution was 3.0, and then 1 mol / L sodium hydroxide solution was added to adjust the pH value to 6.0;

[0054] (2) After stirring for 30 min, pour the silica sol into a polyethylene mold and let it stand to form a wet gel. Cover the surface of the wet gel with 10ml of deionized water, the volume is 1 / 5 of the wet gel, and let it age at room temperature for about 5 hours;

[0055] (3) Soak the wet gel in 100 ml of absolute ethanol for 24 hours, during which the ethanol is replaced at least twice, and the volume ratio of the wet gel to absolute ethanol is 1:2.

[0056] (4) T...

Embodiment 2

[0060] (1) 5ml pure water glass (the substance ratio of the solution: n (Na 2 O):n(SiO 2 ) = 1: 3.1), add 35ml of deionized water to dilute, and at room temperature, pass the diluted solution through an exchange column (diameter 2cm×height 50cm) filled with strong acid styrene cation exchange resin to remove sodium ions and other cations in the water glass . The pH value of the treated solution was 2.5, and 2 mol / L ammonia solution was added to adjust the pH value to 8.0.

[0061] (2) After stirring for 2 hours, pour the silica sol into a glass container and let it stand to form a wet gel. The surface of the wet gel was covered with 5 ml of deionized water and allowed to age at room temperature for about 7 hours.

[0062] (3) Soak the wet gel in 120 ml of methanol for 24 hours, during which the methanol is replaced at least three times, and the volume ratio of the wet gel to methanol is 1:3.

[0063] (4) Then the SiO 2 The wet gel was immersed in a mixture of 17.5 ml of m...

Embodiment 3

[0067] (1) 5ml pure water glass (the substance ratio of the solution: n (Na 2 O):n(SiO 2 )=1:3.1), add 50ml of deionized water to dilute, and at room temperature, pass the diluted solution through an exchange column (diameter 2cm×height 50cm) filled with strong acid styrene cation exchange resin to remove sodium ions and other cations in water glass . The pH value of the treated solution was 2.0, and then 5 mol / L potassium hydroxide solution was added to adjust the pH value to 4.0,

[0068] (2) After stirring for 6 hours, pour the silica sol into a glass container and let it stand to form a wet gel. The surface of the wet gel was covered with 7 ml of deionized water and allowed to age at room temperature for about 8 hours.

[0069] (3) The wet gel was soaked in 55 ml of acetone for 48 hours, during which the acetone was replaced at least 4 times, and the volume ratio of the wet gel to acetone was 1:1.

[0070] (4) Then the SiO 2 The wet gel was immersed in a mixture of 10...

PUM

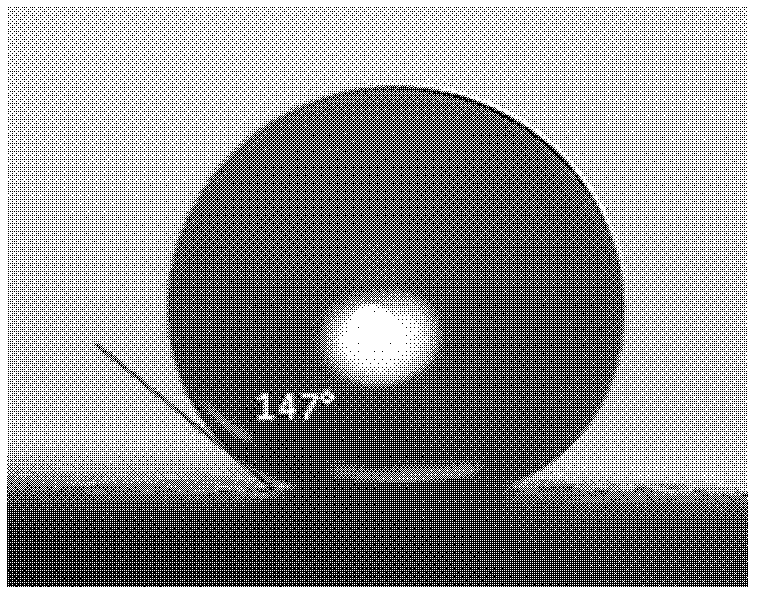

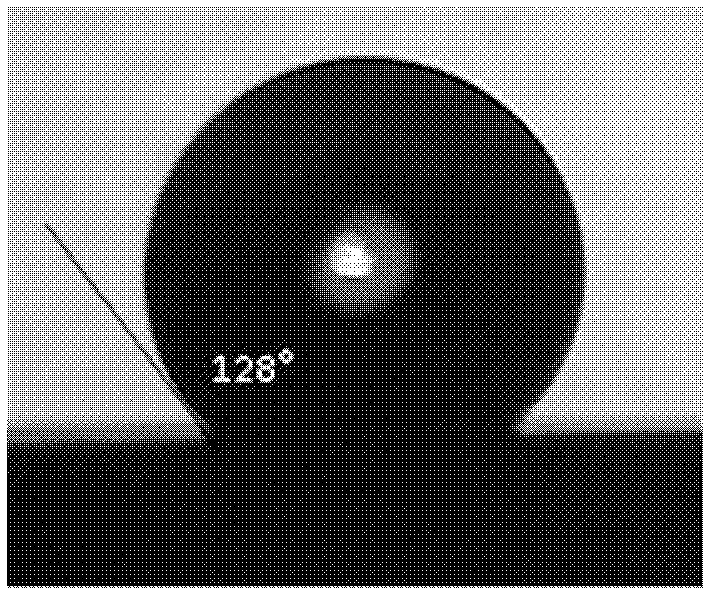

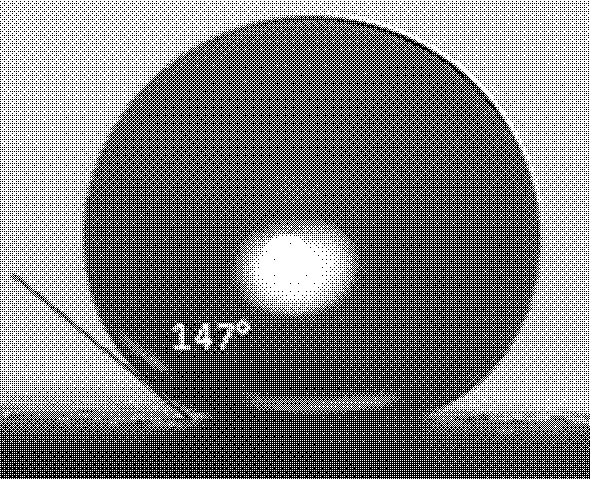

| Property | Measurement | Unit |

|---|---|---|

| Hydrophobic angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap